Positive and negative electrodes and high-energy solid-state vanadium battery using positive and negative electrodes

A technology of positive and negative electrodes and conductive agents, applied in the field of high-energy solid-state vanadium batteries, can solve the problems of electrolyte crystallization, low energy density, liquid leakage, etc., and achieve the effect of improving energy density, high conversion efficiency, and improving energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

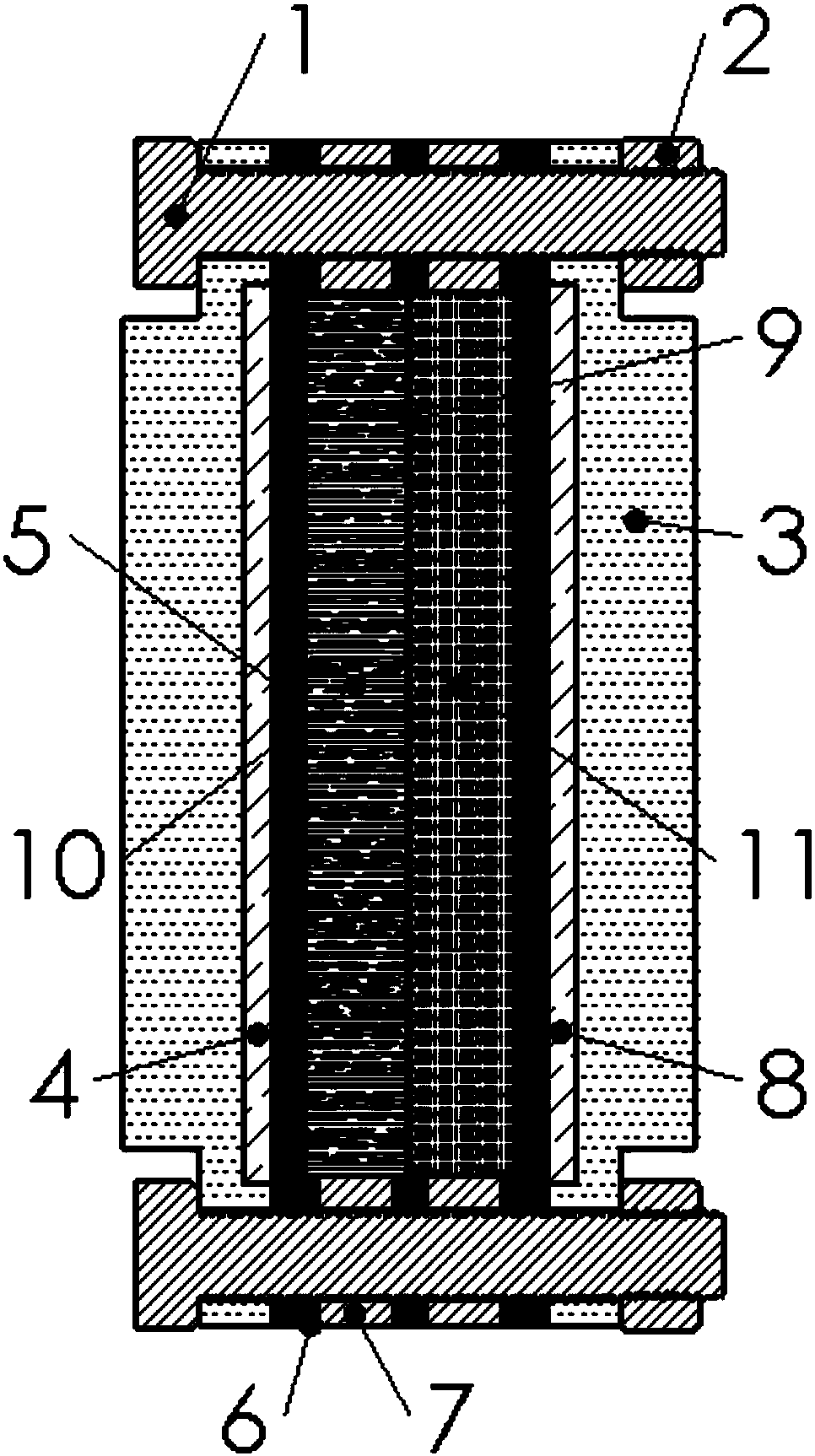

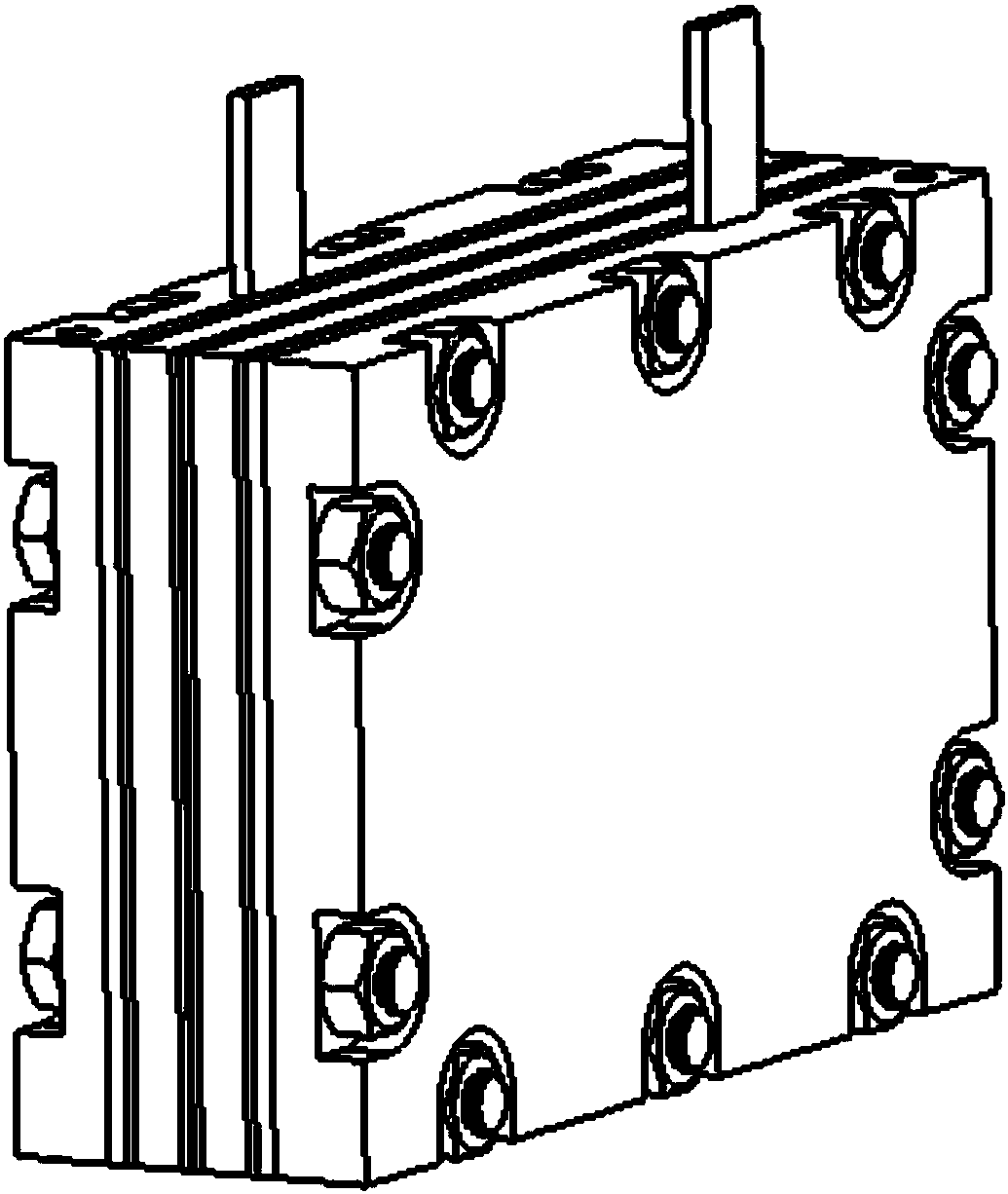

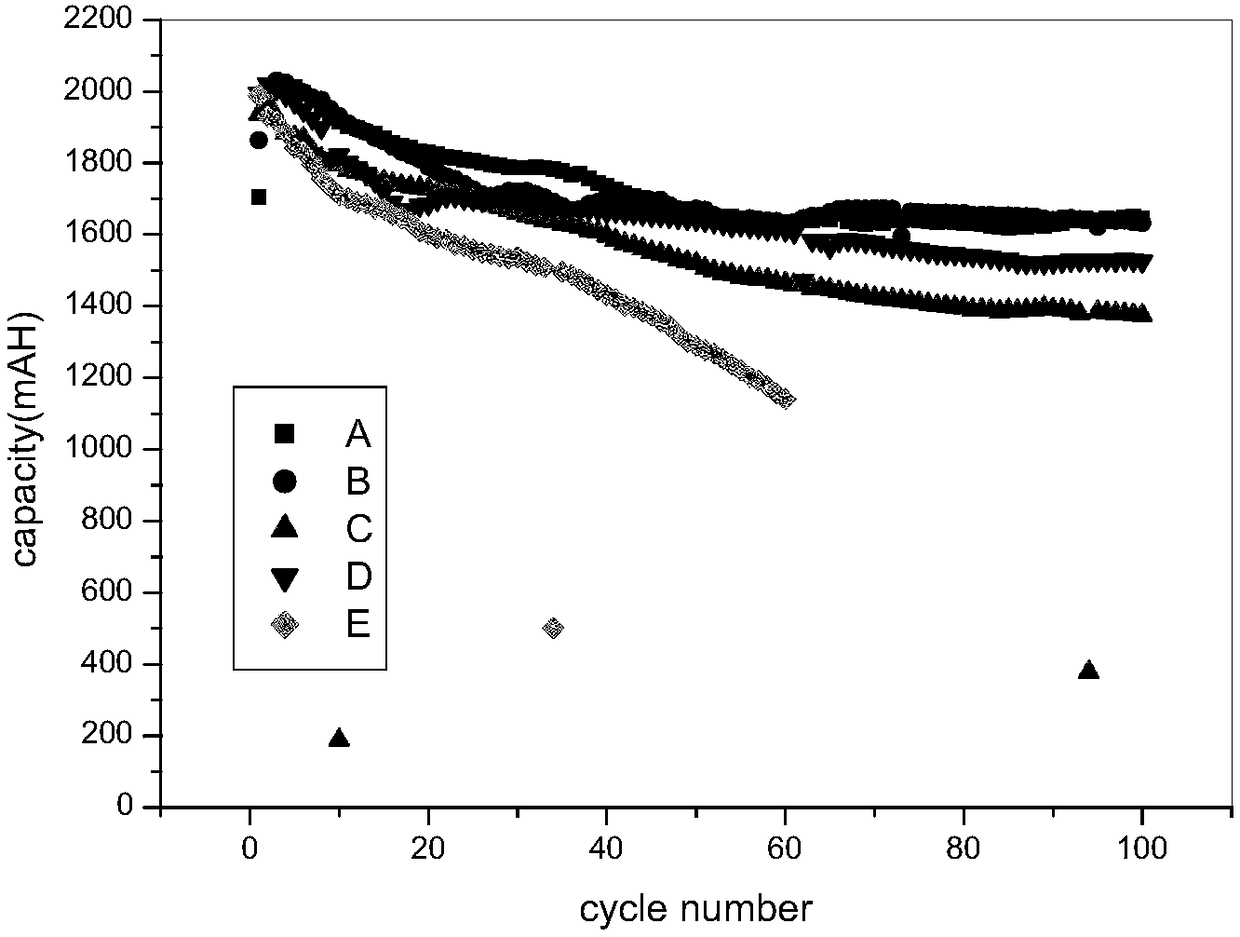

Embodiment 1

[0039] With respect to the conductive agent Ketjen black of 10wt% of vanadium electrolyte, the binder styrene-butadiene rubber of 2wt%, the dispersant SiO of 3wt% 2 After stirring evenly, add it to the vanadium electrolyte: 4.5M (vanadium ion concentration) + 5.0M (acidity), and then stir until a uniform solid substance is formed. Apply the solid substance to the positive and negative electrode seals respectively, and compact it According to the schematic diagram of the battery, the pole, the current collector, the positive electrode, the seal, the diaphragm (ion exchange membrane, Zhejiang Qianqiu Environmental Protection Water Treatment Co., Ltd.), the seal, the negative electrode, the current collector, etc. (Graphite plate, Shanghai Toyo Carbon Co., Ltd.), the pole is placed in the battery casing, and the casing is pressed tightly to make a vanadium solid-state vanadium battery 1.

Embodiment 2

[0041] With respect to the conductive agent graphite powder of 8wt% of vanadium electrolytic solution, the binding agent sodium carboxymethyl cellulose of 5wt%, the dispersant polyacrylamide of 5wt% is stirred evenly and joins vanadium electrolytic solution: 4.5M (vanadium ion Concentration) + 5.0M (acidity), then stir until a uniform solid substance is formed, apply the solid substance to the positive and negative electrode seals respectively, compact and flatten, and then form the positive and negative electrodes; according to the schematic diagram of the battery, sequentially The pole, current collector, positive electrode, seal, diaphragm (ion exchange membrane, Zhejiang Qianqiu Environmental Protection Water Treatment Co., Ltd.), seal, negative electrode, current collector (graphite plate, Shanghai Toyo Carbon Co., Ltd.), pole Put it in the battery casing, and press the casing tightly to make a vanadium solid-state vanadium battery 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com