A kind of submarine vacuum pipeline traffic system and push-push laying method thereof

A vacuum pipeline and transportation system technology, applied in tunnel systems, roads, tracks, etc., can solve problems such as difficult construction, curved pipelines, and slow progress, and achieve the effects of saving construction costs, low construction costs, and simple construction processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

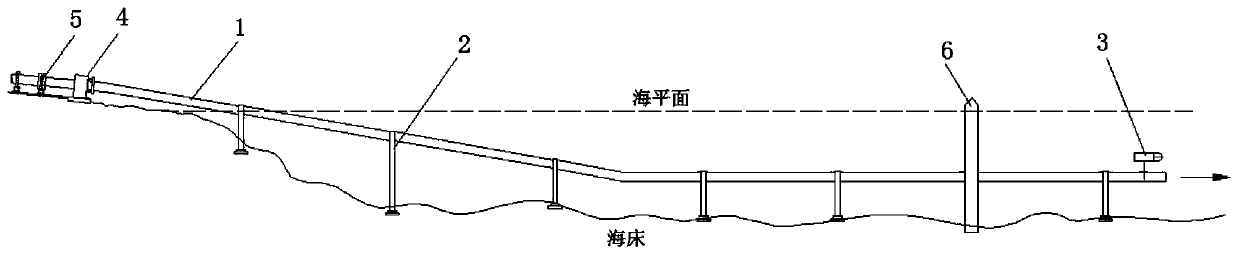

[0040] Such as figure 1 As shown, a submarine vacuum pipeline transportation system includes a pipe pier 2 built on the seabed, a pipe 1 is erected on the pipe pier 2, and the rear end of the pipe 1 located on the coast is connected with a pusher 4 and a welding platform 5. During construction, the welded pipeline 1 is pushed joint by joint by the pusher 4 and laid forward along the designed line direction; the middle part of the submarine vacuum pipeline is provided with a relay push station 6, and the pipeline 1 passes through the relay push station 6. The front end of the first section of the pipeline 1 is provided with a positioning and guiding submersible 3, through which the positioning and guiding submersible 3 ensures that the pipeline 1 accurately enters the erection position of the upper part of the pipe pier 2 that is pre-selected and fixed on the seabed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com