Desulfurization wastewater evaporation and concentration and heat recovery system

A desulfurization wastewater, evaporation and concentration technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problem of high concentration cost, achieve high heat recovery efficiency, improve combustion efficiency, heat source taste less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, further illustrate the present invention.

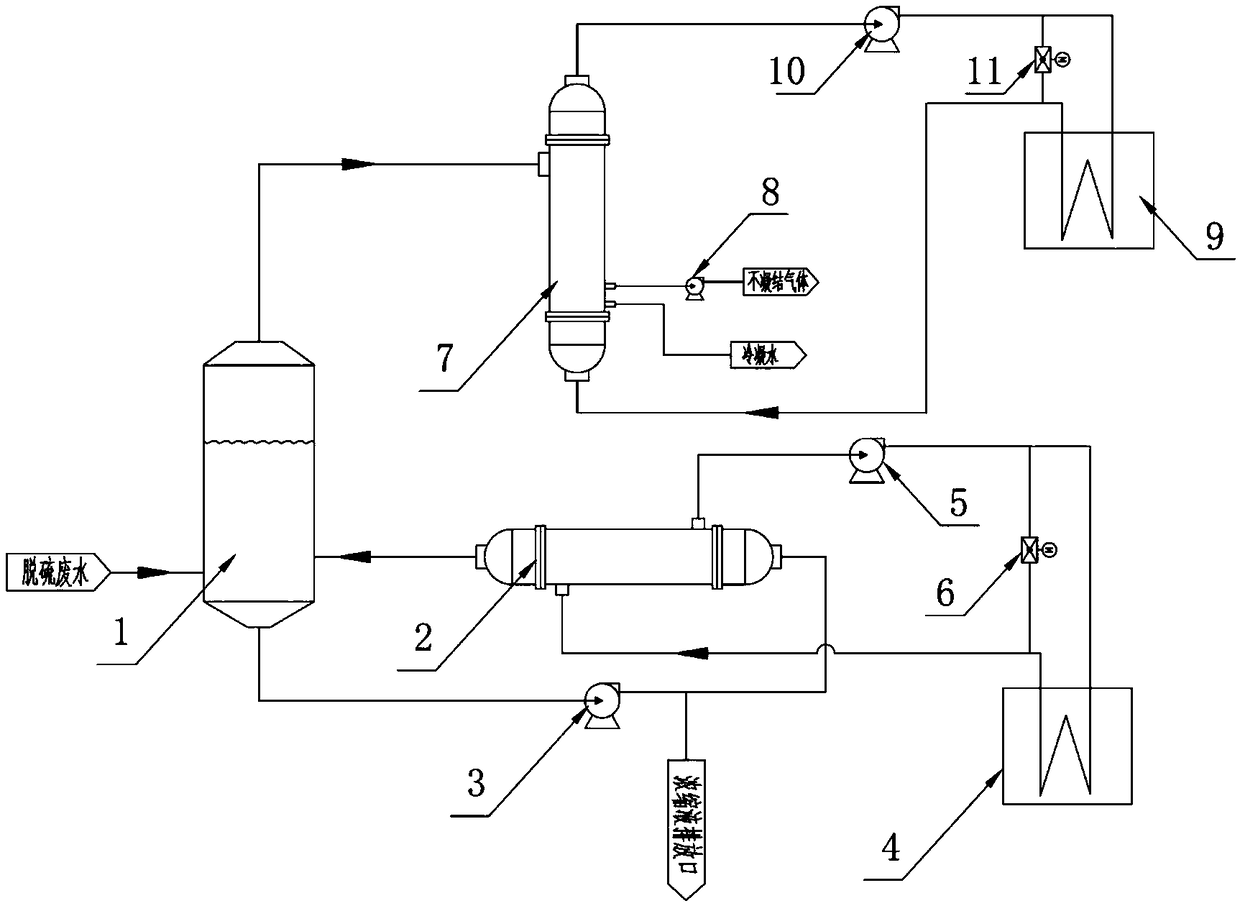

[0027] figure 1 The schematic diagram of the desulfurization wastewater evaporative concentration and heat recovery system provided in this embodiment, the desulfurization wastewater evaporative concentration and heat recovery system consists of a desulfurization wastewater evaporator 1, a desulfurization wastewater heater 2, a desulfurization wastewater circulation pump 3, a boiler flue gas discharge Heat cooler 4, heat medium water circulation pump 5, boiler flue gas exothermic cooler adjustment bypass 6, steam condenser 7, vacuum pump 8, boiler air supply and heat absorption heater 9, cooling water circulation pump 10, boiler air supply and heat absorption Heater adjustment bypass 11 and other components.

[0028] The desulfurization wastewater evaporation device 1, the desulfurization wastewater heater 2, and the desulfurization wastewater circulation pump 3 form the desulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com