A semi-rigid base material for expressway and its preparation process

A semi-rigid base layer and preparation process technology, applied in the field of highway semi-rigid base layer materials and preparation technology, can solve the problems of long-term use, corrosion, reduced service life, etc., achieve good expansion and warpage performance, enhance shrinkage resistance, The effect of improving shrinkage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

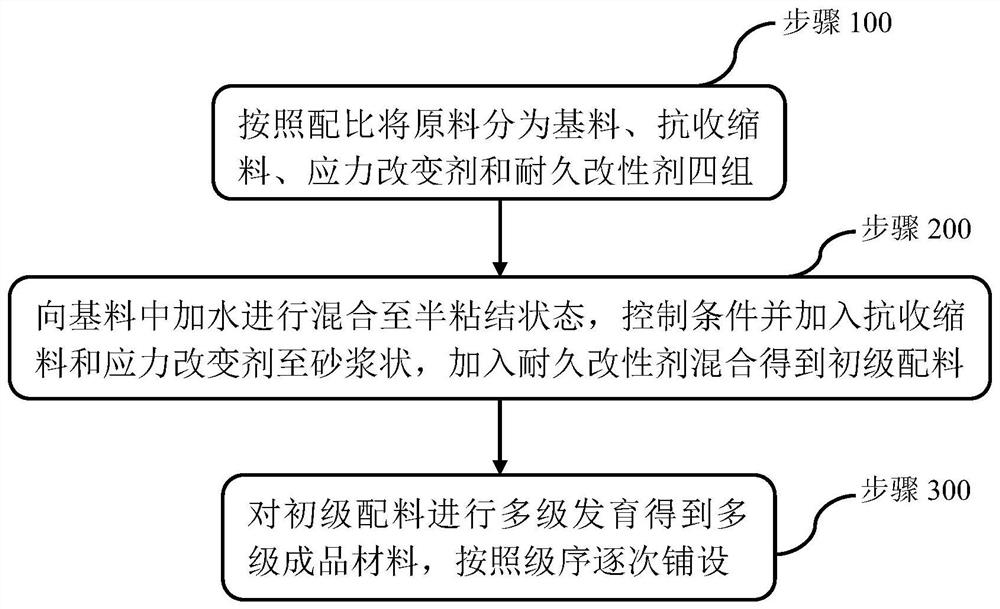

Method used

Image

Examples

Embodiment 1

[0042] The invention provides a semi-rigid base material for highways, comprising the following mass fractions:

[0043] 40 parts of stable mixture, 100 parts of mixed aggregate, 50 parts of cement fly ash gravel, 30 parts of granular asphalt, 10 parts of early strength agent, 30 parts of high elastic fiber, 40 parts of quartz gravel, 10 parts of anti-shrinkage additive, 30 parts of cement soil, 40 parts of polymer concrete, and 10 parts of salt additives.

[0044] The mixed aggregate includes granite, basalt, limestone, dolomite and mica particles, and its composition according to the mass fraction ratio is 7:10:12:8:6.

[0045] The stable mixture includes broken pebbles, natural sand, coarse aggregate, reinforcing additives and quicklimestone, wherein the broken pebbles include particle diameters of 10-20mm, particle diameters of 20-25mm, particle diameters of 25-30mm and particle diameters of 35-40mm, And the mass ratio of particle diameter 10-20mm, particle diameter 20-25...

Embodiment 2

[0048] The present invention also provides a kind of expressway semi-rigid base material, comprising the material of following mass fraction:

[0049] 50 parts of stable mixture, 125 parts of mixed aggregate, 60 parts of cement fly ash gravel, 40 parts of granular asphalt, 15 parts of early strength agent, 35 parts of high elastic fiber, 50 parts of quartz gravel, 13 parts of anti-shrinkage additive, 35 parts of cement soil, 45 parts of polymer concrete, and 15 parts of salt additives.

[0050] The mixed aggregate includes granite, basalt, limestone, dolomite and mica particles, and its composition according to the mass fraction ratio is 9:13:13:10:8.

[0051] The stable mixture includes broken pebbles, natural sand, coarse aggregate, reinforcing additives and quicklimestone, wherein the broken pebbles include particle diameters of 10-20mm, particle diameters of 20-25mm, particle diameters of 25-30mm and particle diameters of 35-40mm, And the mass ratio of particle diameter 1...

Embodiment 3

[0054] The invention provides a semi-rigid base material for highways, comprising the following mass fractions:

[0055] 60 parts of stable mixture, 150 parts of mixed aggregate, 70 parts of cement fly ash gravel, 50 parts of granular asphalt, 20 parts of early strength agent, 40 parts of high elastic fiber, 60 parts of quartz gravel, 6 parts of anti-shrinkage additive, 40 parts of cement soil, 50 parts of polymer concrete, 30 parts of salt additives.

[0056] The mixed aggregate includes granite, basalt, limestone, dolomite and mica particles, and its composition according to the mass fraction ratio is 10:16:14:11:9.

[0057] The stable mixture includes broken pebbles, natural sand, coarse aggregate, reinforcing additives and quicklimestone, wherein the broken pebbles include particle diameters of 10-20mm, particle diameters of 20-25mm, particle diameters of 25-30mm and particle diameters of 35-40mm, And the mass ratio of particle diameter 10-20mm, particle diameter 20-25mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com