Solid catalyst component used for olefin polymerization and catalytic system thereof

A solid catalyst and olefin polymerization technology, applied in the field of polyolefin catalysts, can solve the problems of low bulk density and poor particle shape of resin powder, and achieve the effects of good particle shape, uniform distribution and high bulk specific gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

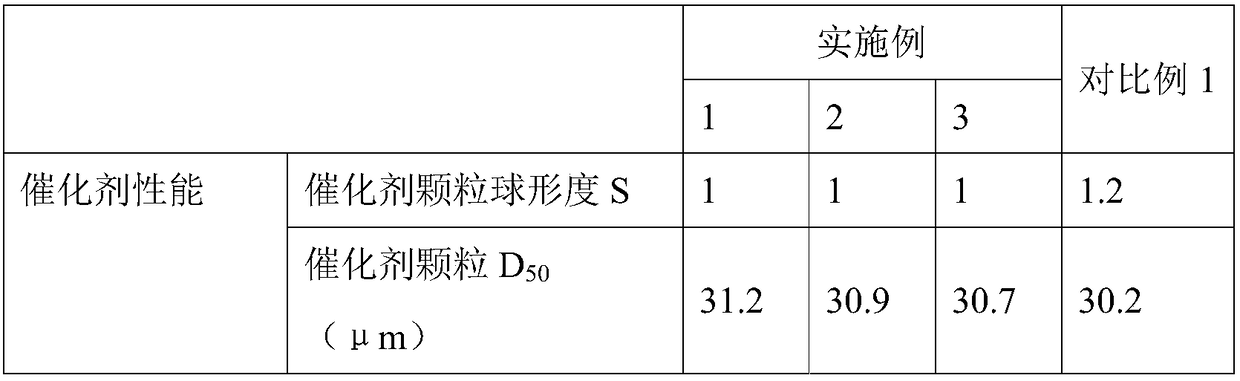

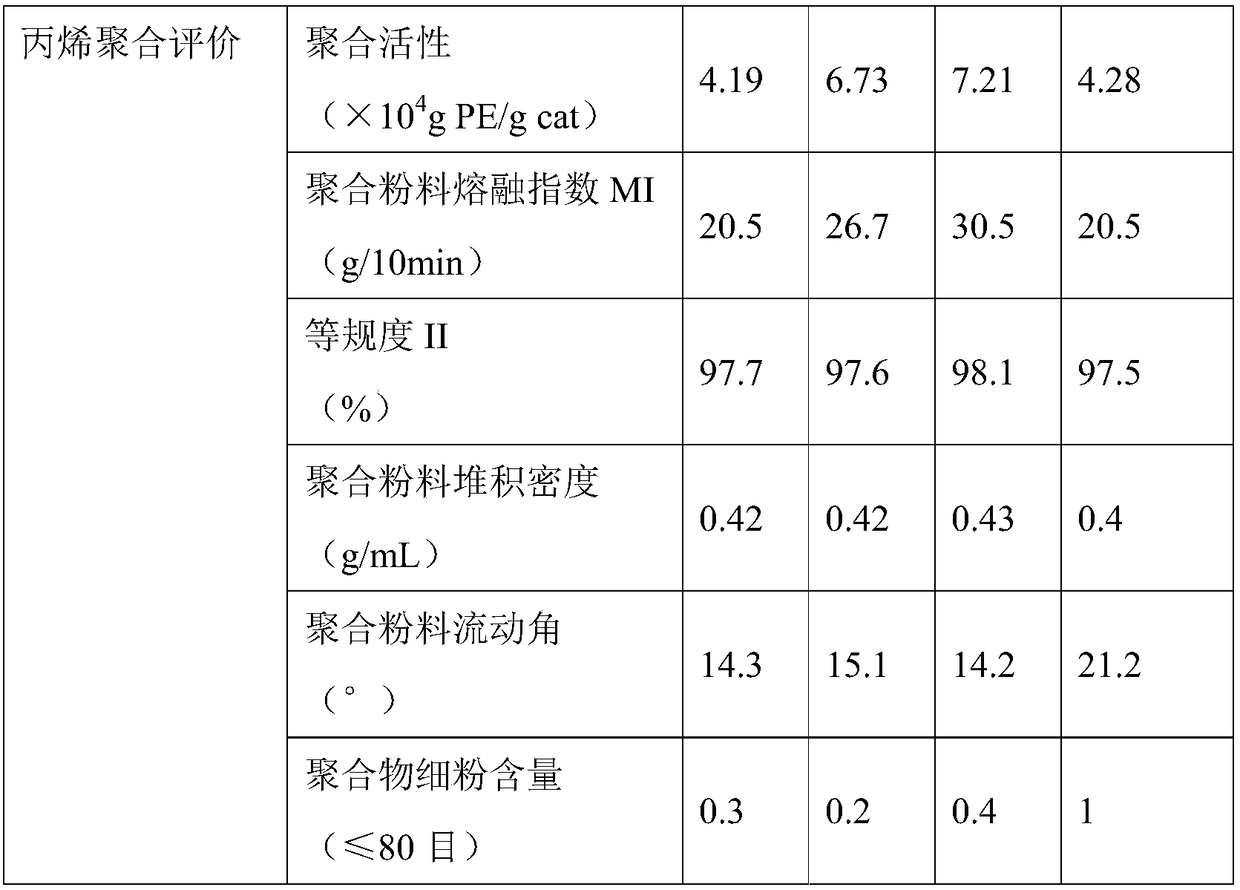

Examples

Embodiment 1

[0041] a) Preparation of Magnesium Ethoxide Microspheres

[0042] 57g (0.5mol) Mg (OC 2 h 5 ) 2 The solid powder and 200mL ethanol were put into a 500mL grinding tank, and were ground for 5 hours with the PM-400 ball mill of Germany Lai Chi Company to obtain Mg(OC) with an average particle size of 5.5 μm. 2 h 5 ) 2 suspension.

[0043] Get the Mg(OC 2 h 5 ) 2 100 mL of the suspension was transferred to the N 2 50 mL of ethanol was added to the replaced four-necked reaction flask, and treated with a high-speed disperser (Krupp Supraton TM type S200) at 60° C. for 20 hours to form a gel-like dispersion.

[0044] Add 0.22 g of dry ice (0.005 mol) to the gel dispersion obtained above, stir and react for 1 hour to obtain a gel-like dispersion suspension of magnesium ethoxide containing carboxylated magnesium ethoxide solution.

[0045] The above-obtained gel-like dispersion suspension was spray-dried (Buchi B290) to obtain solid microsphere particles. The spray conditions...

Embodiment 2

[0052] a) Preparation of Magnesium Ethoxide Microspheres

[0053] With embodiment 1.

[0054] b) Preparation of solid catalyst components

[0055] In a 500mL reaction kettle that has been repeatedly replaced with high-purity nitrogen, add 70mL of toluene and 30mL of titanium tetrachloride, cool down to -5°C, take 10g of the above-mentioned magnesium alkoxide and 50mL of toluene to prepare a suspension, and then mix the prepared Add the suspension to the kettle, slowly raise the temperature to 110°C, add 2.5mL of 4-ethyl-3,5-heptanediol dibenzoate during the heating process, keep the temperature at 110°C for 2 hours, and then press filter the liquid . Then add 120mL of toluene and 30mL of titanium tetrachloride mixed solution and raise the temperature to 110°C and stir for 1 hour, treat like this 3 times, filter off the liquid, wash the obtained solid 4 times with 150mL of hexane, filter off the liquid and dry to obtain solid catalyst components.

[0056] c) Polymerization ...

Embodiment 3

[0059] a) Preparation of Magnesium Ethoxide Microspheres

[0060] With embodiment 1.

[0061] b) Preparation of solid catalyst components

[0062] In a 500mL reaction kettle that has been repeatedly replaced with high-purity nitrogen, add 70mL of toluene and 30mL of titanium tetrachloride, cool down to -5°C, take 10g of the above-mentioned magnesium alkoxide and 50mL of toluene to prepare a suspension, and then mix the prepared Add the suspension into the kettle, slowly raise the temperature to 110°C, add 1.5 mL of diisobutyl phthalate and 1.5 mL of 2-isopropyl-2-isoamyl-1,3-dimethoxypropane during the heating process mL, keep the temperature at 110°C for 2 hours, then press filter the liquid. Then add 120mL of toluene and 30mL of titanium tetrachloride mixed solution and raise the temperature to 110°C and stir for 1 hour, treat like this 3 times, filter off the liquid, wash the obtained solid 4 times with 150mL of hexane, filter off the liquid and dry to obtain solid catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com