Latent light-sensitive microcapsule epoxy curing agent and preparation method thereof

An epoxy curing agent and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, adhesives, etc., can solve the problems of incomplete rupture of microcapsules, long time required, insufficient rapid curing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

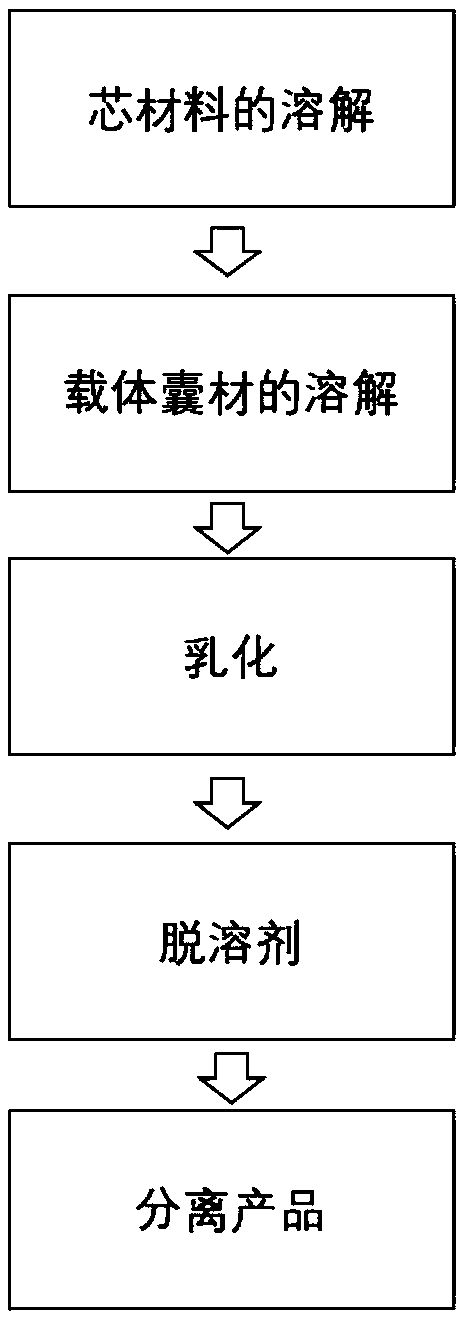

[0067] combine figure 1 Illustrate that the present invention also provides a kind of preparation method of latent photosensitive microcapsule epoxy curing agent, comprises the following steps:

[0068] Step 1, the preparation of polymers whose general structure is a3, b3 or c3

[0069] Step 1-1, dissolve 3-hydroxymethyl-2 nitrobenzyl alcohol a1 or 4-hydroxymethyl-2 nitrobenzyl alcohol b1 or 5-hydroxymethyl-2 nitrobenzyl alcohol c1 in dry Dichloromethane or chloroform solvent is used to make a solution with a mass fraction of 0.1-10%. The solution is added to a three-necked flask equipped with a stirrer, and then the 4-dimethylaminopyridine catalyst is added. After stirring evenly, triethyl After amine, add 2-bromo-2-methyl-propionyl bromide dropwise, stir at room temperature, react for 20-30 hours, quench the reaction with methanol, dilute the reaction solution with tetrahydrofuran solvent, use 200-500 mesh basic silica gel or alkali Filter the triethylamine hydrochloride b...

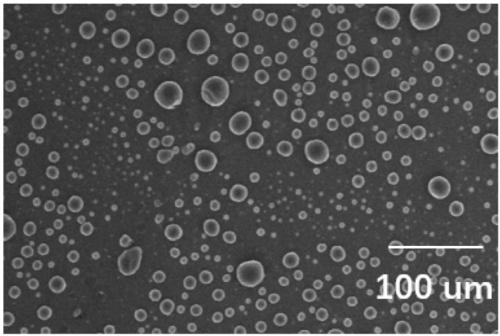

Embodiment 1

[0094] The structure of the microcapsule wall material is shown in the figure below.

[0095]

[0096] Preparation of polymer a-1

[0097] In a three-neck flask equipped with a stirrer, dissolve 183 mg of 3-hydroxymethyl-2-nitrobenzyl alcohol (a1) in 90 mL of dry dichloromethane, and then add 1.83 mg of 4-dimethylaminopyridine. After stirring evenly, after adding 3 mg of triethylamine, 459.8 mg of 2-bromo-2-methyl-propionyl bromide was added dropwise, stirred at room temperature, reacted for 20 hours, and quenched the reaction with 18 mL of methanol. Add 10 mL of tetrahydrofuran solvent to the reaction solution, filter triethylamine hydrochloride with 200 mesh basic aluminum oxide, drop the filtrate into diethyl ether, precipitate precipitate, filter with Buchner funnel, and wash with deionized water several times, After vacuum drying at 110°C for 10 h, 394 mg of intermediate a2 was obtained, with a yield of 82%.

[0098] Mass spectrometry, [M+H] + : 479.96; elemental anal...

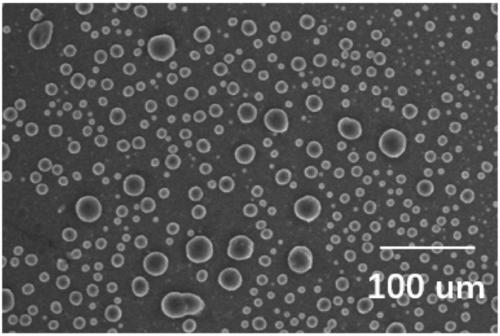

Embodiment 2

[0106] microcapsule wall material

[0107]

[0108] Preparation of polymer a-2

[0109] In a three-neck flask equipped with a stirrer, dissolve 183 mg of 3-hydroxymethyl-2-nitrobenzyl alcohol (a1) in 90 mL of dry dichloromethane, and then add 1.83 mg of 4-dimethylaminopyridine. After stirring evenly, after adding 3 mg of triethylamine, 459.8 mg of 2-bromo-2-methyl-propionyl bromide was added dropwise, stirred at room temperature, reacted for 20 hours, and quenched the reaction with 18 mL of methanol. Add 10 mL of tetrahydrofuran solvent to the reaction solution, filter triethylamine hydrochloride with 200 mesh basic aluminum oxide, drop the filtrate into diethyl ether, precipitate precipitate, filter with Buchner funnel, and wash with deionized water several times, After vacuum drying at 110°C for 10 h, 394 mg of intermediate a2 was obtained, with a yield of 82%.

[0110] Mass spectrometry, [M+H] + : 479.96; elemental analysis, C 39.93H 3.97Br 33.20N 2.90O19.94. Infrare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com