Ternary copolymerized composite material of functional graphene in-situ polymerized polyester and preparation method and special device thereof

A technology of functional graphene and composite materials, applied in the field of ternary copolymer composite materials and their preparation, can solve problems such as unfavorable resource saving, large-scale production, insignificant performance improvement, and large graphene content, and achieve good mechanical properties and comprehensive Performance, good dispersion peeling and shearing, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

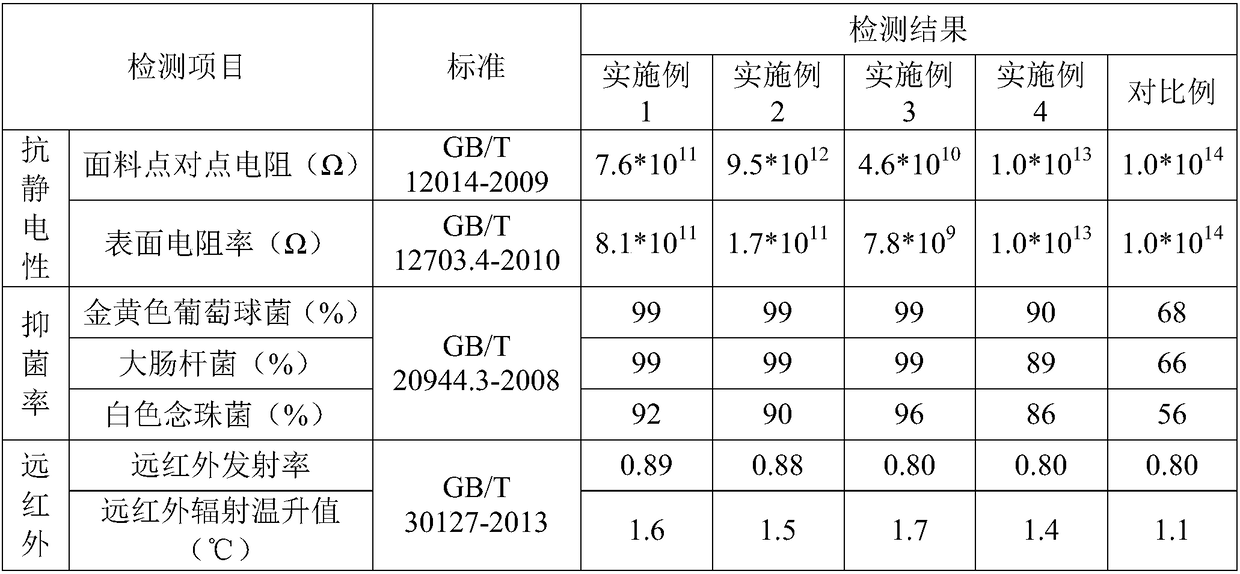

Embodiment 1

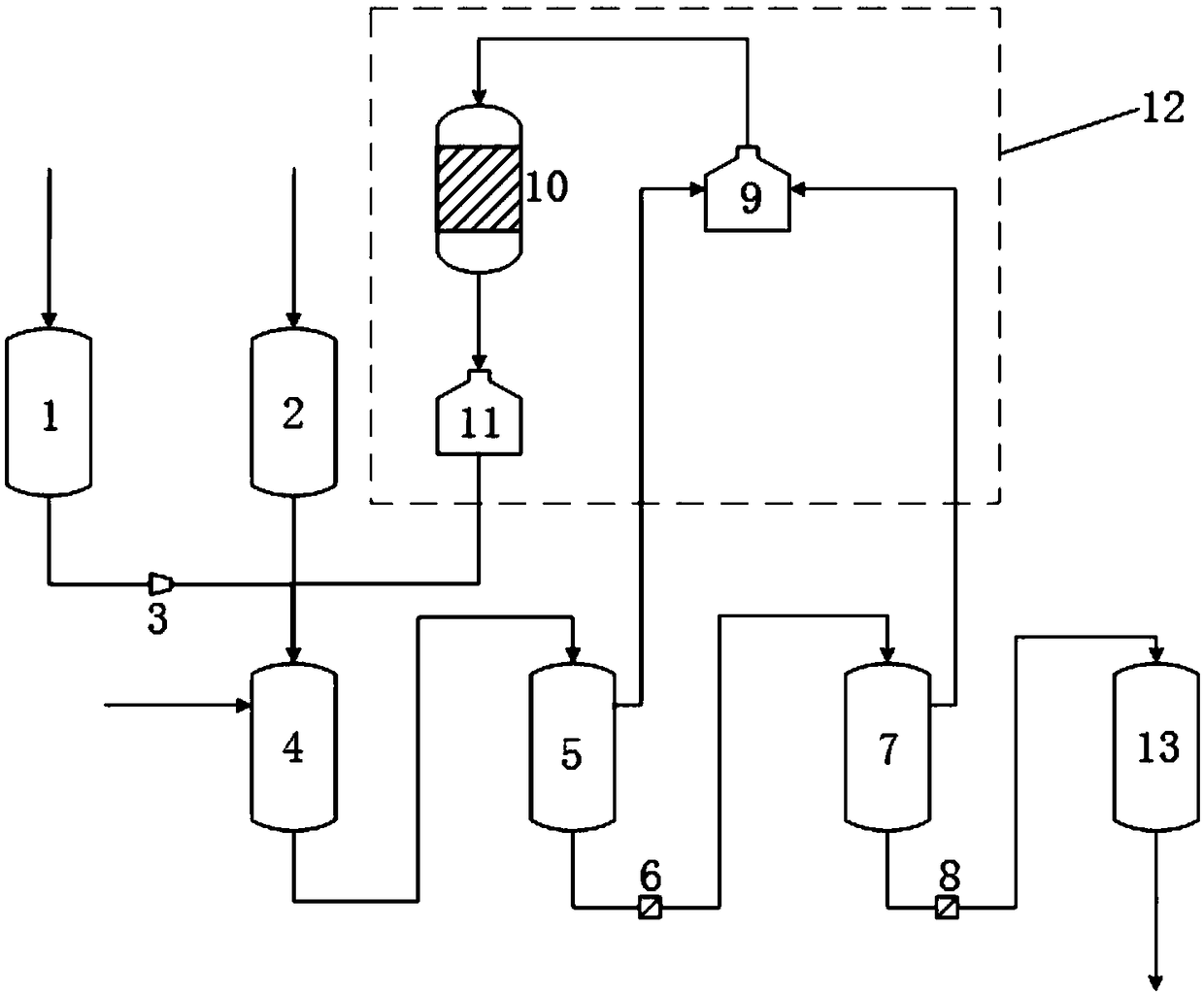

[0041] A special device for preparing functional graphene in-situ polymerized polyester ternary copolymerization composite materials of this embodiment, such as figure 2 As shown, it includes a raw material addition device, a raw material preparation device 4, an esterification reaction device 5, a prepolymer filtration device 6, a polycondensation reaction device 7 and a melt filtration device 8 connected in sequence by pipelines, and the raw material addition device includes a graphene addition device 1 and auxiliary material adding device 2, graphene adding device 1, auxiliary material adding device 2 and raw material preparation device 4 are all provided with high-shear emulsifier and ultrasonic disperser, between graphene adding device 1 and raw material preparation device 4 is provided with High pressure homogenizer. The waste ports of the esterification reaction device 5 and the polycondensation reaction device 7 are connected to the raw material preparation device 4 ...

Embodiment 2

[0068] The preparation device of the ternary copolymerization composite material of the functional graphene in-situ polymerized polyester of the present embodiment is the same as that of Example 1, and the preparation method is as follows:

[0069]Amino functional graphene and auxiliary materials (comprising titanium dioxide, catalyst) are dispersed in ethylene glycol to obtain functional graphene dispersion liquid and auxiliary material dispersion liquid respectively; then remaining ethylene glycol and purified terephthalic acid, functional graphene dispersion liquid , the auxiliary material dispersion liquid is added to the reaction kettle for dispersion, and then the esterification and polycondensation reactions are carried out in sequence to obtain the ternary copolymerization composite material. Among them, the mass of functional graphene accounts for 0.5% of the terpolymer composite material.

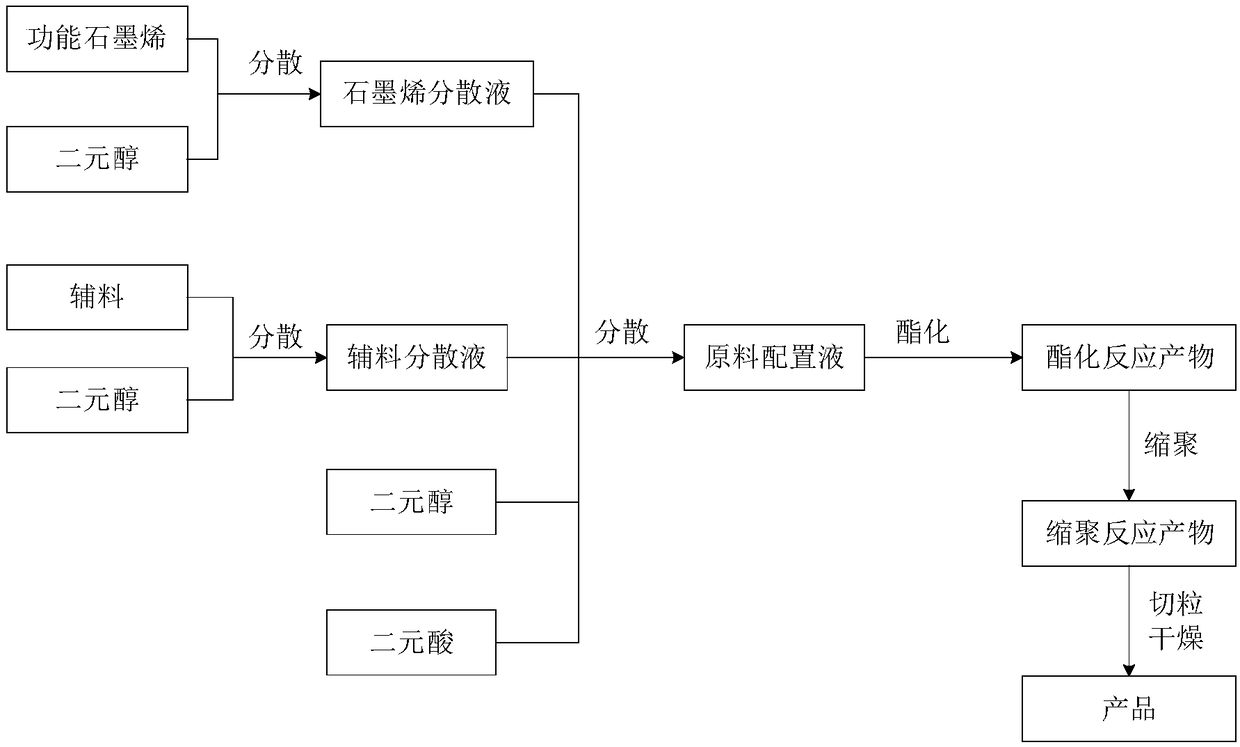

[0070] Such as figure 1 As shown, it specifically includes the following ste...

Embodiment 3

[0081] The preparation device of the ternary copolymerization composite material of the functional graphene in-situ polymerized polyester of the present embodiment is the same as that of Example 1, and the preparation method is as follows:

[0082] Carboxyl functional graphene and auxiliary materials (including catalyst) are dispersed in ethylene glycol to obtain functional graphene dispersion liquid and auxiliary material dispersion liquid respectively; then remaining ethylene glycol and purified terephthalic acid, functional graphene dispersion liquid, auxiliary material The dispersion liquid is added into the reaction kettle for dispersion, and then the esterification and polycondensation reactions are carried out in sequence to obtain the ternary copolymerization composite material. Among them, the mass of functional graphene accounts for 2% of the terpolymer composite material.

[0083] Such as figure 1 As shown, it specifically includes the following steps:

[0084] (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com