Cadmium-contaminated soil remedying agent

A technology for cadmium-contaminated soil and a remediation agent, applied in the field of soil remediation, can solve problems such as poor remediation effect of cadmium-contaminated soil, and achieve the effects of reducing toxic effects, improving soil fertility, and reducing mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

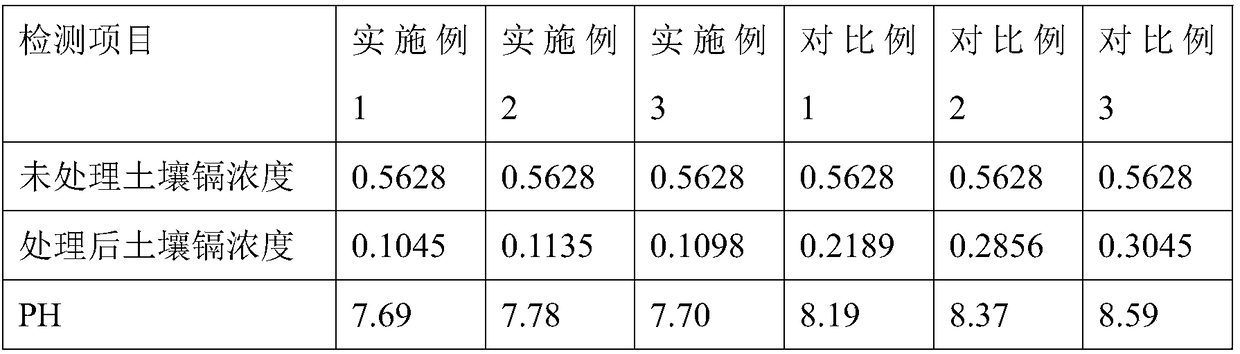

Examples

preparation example Construction

[0027] Preparation of modified attapulgite: Mix attapulgite and isocyanate at a mass ratio of 12-20:1, stir magnetically at 450-700r / min for 30-50min, add attapulgite mass 6-10% silane coupling agent KH-560, grind at 350-550r / min for 2-4 hours, pass through a 200-mesh sieve, collect the sieved particles, add fulvic acid, salt material, and additives in a mass ratio of 7-12:3:1:2, and mix with liquid After nitrogen spraying and freezing, the frozen material is obtained. The frozen material is mixed with ball milling medium at a mass ratio of 8 to 15:1, and mixed with zirconia ball milling beads at a mass ratio of 20 to 30:1. After 1-3 hours, the modified attapulgite is obtained.

[0028] The preparation method of composite base material, comprises the steps:

[0029] (1) According to the mass ratio of 5-8:2, take basalt and muscovite and grind them in a pulverizer, pass through a 200-mesh sieve, collect the sieved particles, add reagent A to mix and stir at a mass ratio of 1:7...

Embodiment 1

[0036] Salt material: Mix zinc sulfate and zinc chloride at a mass ratio of 5:1 to obtain salt material.

[0037] Reagent A: Mix 20% sodium carbonate solution and sodium citrate at a mass ratio of 6:1 to obtain reagent A.

[0038] Reagent B: Mix 70% ethanol solution and polyvinylpyrrolidone at a mass ratio of 12:1 to obtain Reagent B.

[0039] Auxiliary: take hydroxyapatite and vermiculite according to the mass ratio of 5:2, grind them through a 150-mesh sieve in a pulverizer, and collect the sieved particles to obtain the auxiliary agent.

[0040] Ball milling medium: Mix acetone and glycerin at a volume ratio of 4:1 to obtain a ball milling medium.

[0041] Emulsifier: Mix polyacrylamide and soybean lecithin at a mass ratio of 7:2 to obtain an emulsifier.

[0042] Additive: Mix methylphenol and methoxyphenol at a mass ratio of 3:1 to obtain the additive.

[0043] Preparation of modified attapulgite: Mix attapulgite and isocyanate at a mass ratio of 12:1, stir magnetically a...

Embodiment 2

[0052] Salt material: Mix zinc sulfate and zinc chloride at a mass ratio of 5:3 to obtain salt material.

[0053] Reagent A: Mix 20% sodium carbonate solution and sodium citrate at a mass ratio of 10:1 to obtain reagent A.

[0054] Reagent B: Mix 70% ethanol solution and polyvinylpyrrolidone at a mass ratio of 20:1 to obtain Reagent B.

[0055] Auxiliary: take hydroxyapatite and vermiculite according to the mass ratio of 8:2, crush them through a 150-mesh sieve in a pulverizer, and collect the sieved particles to obtain the auxiliary agent.

[0056] Ball milling medium: Mix acetone and glycerin at a volume ratio of 8:1 to obtain a ball milling medium.

[0057] Emulsifier: Mix polyacrylamide and soybean lecithin at a mass ratio of 12:2 to obtain an emulsifier.

[0058] Additive: Mix methylphenol and methoxyphenol at a mass ratio of 6:1 to obtain the additive.

[0059] Preparation of modified attapulgite: Mix attapulgite and isocyanate at a mass ratio of 20:1, stir magnetical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com