Vegetable insulating oil composition as well as preparation method and application thereof

A technology of vegetable insulating oil and composition, applied in lubricating composition, petroleum industry, etc., can solve the problems of high viscosity of insulating oil, difficult to biodegrade, easy to solidify, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] As a preferred version, the preparation method of the vegetable oil fatty acid monohydric alcohol ester comprises the steps:

[0042] After the aliphatic monohydric alcohol is heated and vaporized, it is continuously sprayed into the vegetable oil mixed with the catalyst, and the esterification reaction or transesterification reaction is carried out at 100-190°C to obtain the esterification product or the transesterification product;

[0043] The esterification product or the transesterification product is subjected to distillation and purification, and the vegetable oil fatty acid monohydric alcohol ester is collected.

[0044] As a preferred solution, the catalyst is used in an amount of 0.01-0.5% by total weight of vegetable oil and aliphatic monohydric alcohol.

[0045] As a preferred solution, a stabilizer may also be added when preparing the vegetable oil fatty acid monohydric alcohol ester, and the stabilizer is selected from propylene glycol methyl ether acetate...

Embodiment 1

[0065] The present embodiment has prepared vegetable oil fatty acid monohydric alcohol ester 1#, specifically comprises the following steps:

[0066] 1. Weigh 60kg of coconut oil, 40kg of absolute ethanol and 0.01kg of aluminum oxide respectively, and set aside;

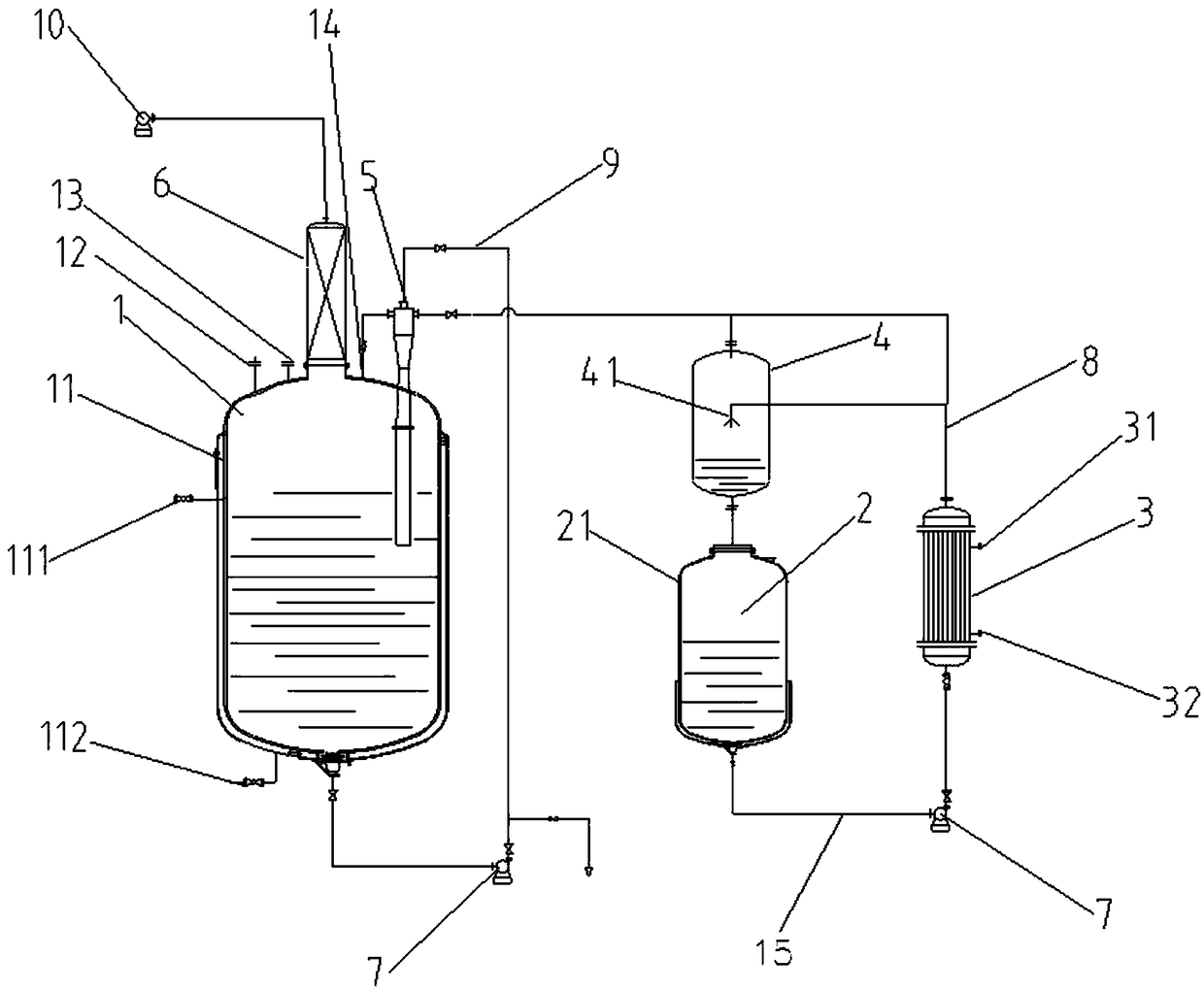

[0067] 2. Add coconut oil and alumina in the reaction kettle in advance, heat to 100°C, start the circulation pump, and return to the reaction kettle through the jet pump;

[0068] 3. The absolute ethanol is converted into a gas phase through a gasifier, and after being efficiently mixed by a high-pressure jet pump, it is sprayed into the reaction kettle. At 100°C, it is esterified with coconut oil to obtain an esterified product, and the reaction time is 1.5 hours;

[0069] 4. Transfer the esterification product into a distillation tower, carry out distillation and purification under the condition of residual pressure of 50Pa and temperature of 120-240°C, remove unreacted monoalcohol, mono / diester, black oil, etc., ...

Embodiment 2

[0071] The present embodiment has prepared vegetable oil fatty acid monoalcohol ester 2#, specifically comprises the following steps:

[0072] 1. Take by weighing 70kg of coconut oil, 30kg of n-propanol, 0.5kg of aluminum trichloride, and 0.1kg of propylene glycol methyl ether acetate, respectively, for subsequent use;

[0073] 2. Add coconut oil and aluminum trichloride to the reaction kettle in advance, heat it to 160°C, start the circulation pump, and return it to the reaction kettle through the jet pump;

[0074] 3. The propanol is converted into a gas phase through a gasifier, injected into the reactor by a high-pressure jet pump, and subjected to an esterification reaction with coconut oil at 190° C. to obtain an esterified product, and the reaction time is 1.5 hours;

[0075] 4. Transfer the esterification product into a distillation tower, carry out distillation and purification under the conditions of a residual pressure of 50 Pa and a temperature of 120-220°C to remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com