Rosa roxburghii tratt fruity beer and preparation method thereof

A prickly pear and beer technology, applied in the field of beer, can solve the problems of fruity beer with poor taste and unable to meet the needs of life, and achieve the effect of simple and easy preparation method and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

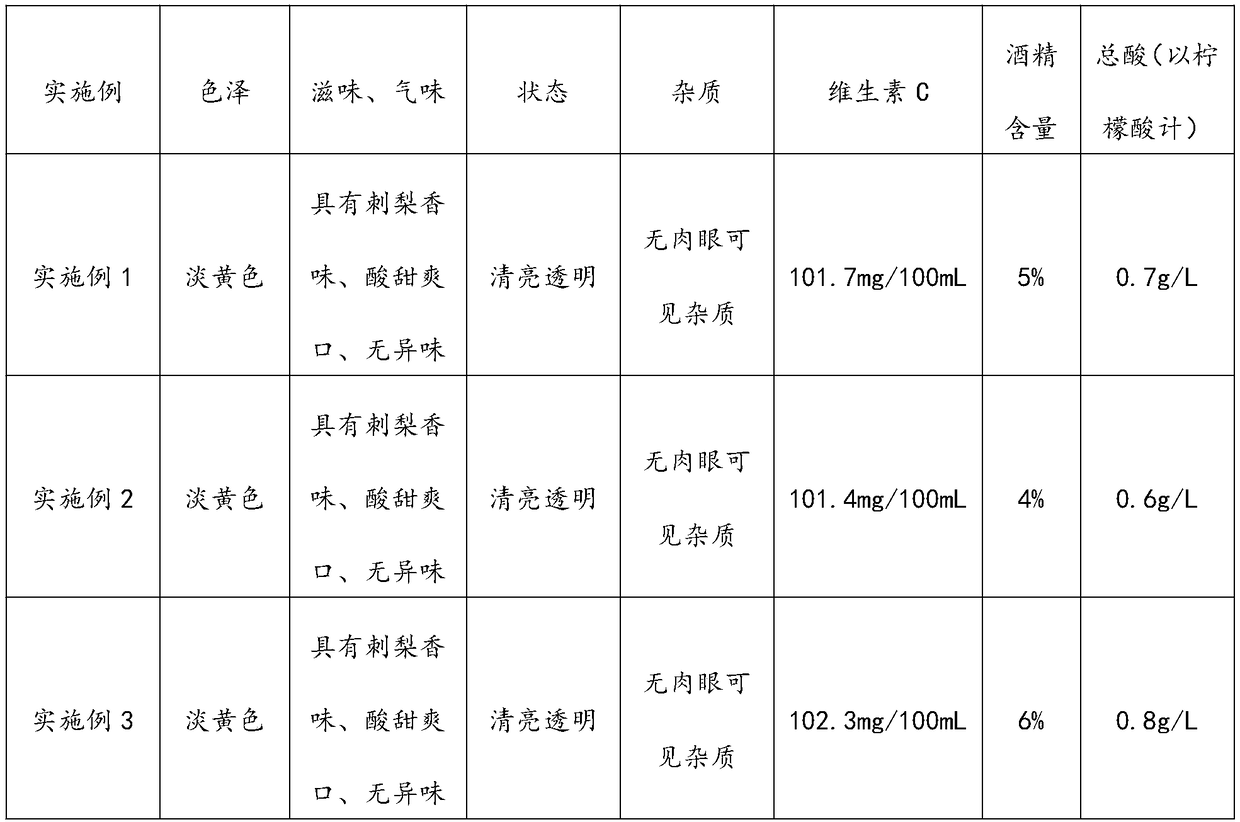

Examples

Embodiment 1

[0026] A. After crushing 150kg of malt into 100 mesh, add 50kg of water for saccharification, the saccharification time is 20min, and the saccharification temperature is controlled at 45°C, then filter to obtain the filtrate, then add 30kg of hops and boil for 20min, after boiling, cool naturally and set aside;

[0027] B. Add the cooled filtrate in step A to a fermenter for oxygenation treatment for 30 minutes, then add 0.3 kg of yeast to ferment, the fermentation temperature is 13° C., and the fermentation time is 7 days. After fermentation, filter and sterilize to obtain the filtrate for subsequent use;

[0028] C, choose the thorn pear 15kg that is free from insect damage, remove the thorns and seeds and clean and cut into several pieces, then squeeze the juice and filter to obtain the juice filtrate, which is for subsequent use;

[0029] D, combine the filtrate obtained in step B with the juice filtrate obtained in step C and bifidosaccharide 1.7kg, citric acid 1kg, honey ...

Embodiment 2

[0031] A. After crushing 160kg of malt into 130 mesh, add 60kg of water for saccharification, the saccharification time is 25min, and the saccharification temperature is controlled at 48°C, then filter to obtain the filtrate, then add 35kg of hops and boil for 25min, cool naturally after boiling, and set aside;

[0032] B. Add the filtrate cooled in step A to a fermenter for oxygenation treatment for 35 minutes, then add 0.6 kg of yeast to ferment, the fermentation temperature is 15 ° C, and the fermentation time is 7.5 days. After fermentation, filter and sterilize to obtain the filtrate for future use ;

[0033] C, choose the Rosa roxburghii 18kg that does not have insect damage, remove the thorn and remove the seeds and clean and cut into several pieces, then extract the juice and filter to obtain the juice filtrate, for subsequent use;

[0034] D, the juice filtrate obtained in step B and the juice filtrate obtained in step C and acesulfame potassium 1.8kg, citric acid 2kg...

Embodiment 3

[0036] A. After crushing 170kg of malt into 150 mesh, add 70kg of water for saccharification, the saccharification time is 30min, and the saccharification temperature is controlled at 52°C, then filter to obtain the filtrate, then add 40kg of hops and boil for 30min, after boiling, cool naturally and set aside;

[0037] B. Add the cooled filtrate in step A to a fermenter for oxygenation treatment for 40 minutes, then add 0.8 kg of yeast to ferment, the fermentation temperature is 17° C., and the fermentation time is 8 days. After fermentation, filter and sterilize to obtain the filtrate for subsequent use;

[0038] C, choose thorn pear 20kg that is free from insect pests, remove the thorns and seeds and clean, and cut into several pieces, then squeeze the juice and filter to obtain the juice filtrate, which is for subsequent use;

[0039] D. Combine the filtrate obtained in step B with the juice filtrate obtained in step C and stevioside 1.9kg, citric acid 3kg, honey 0.4kg, mal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com