Method for testing cementing strength of cement first cementing surface of oil well

A bonding strength, oil well cement technology, applied in the direction of strength characteristics, the use of stable tension/pressure test material strength, the preparation of test samples, etc. and other problems, to achieve the effect of simple and fast production, simple and convenient sample preparation, and true and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

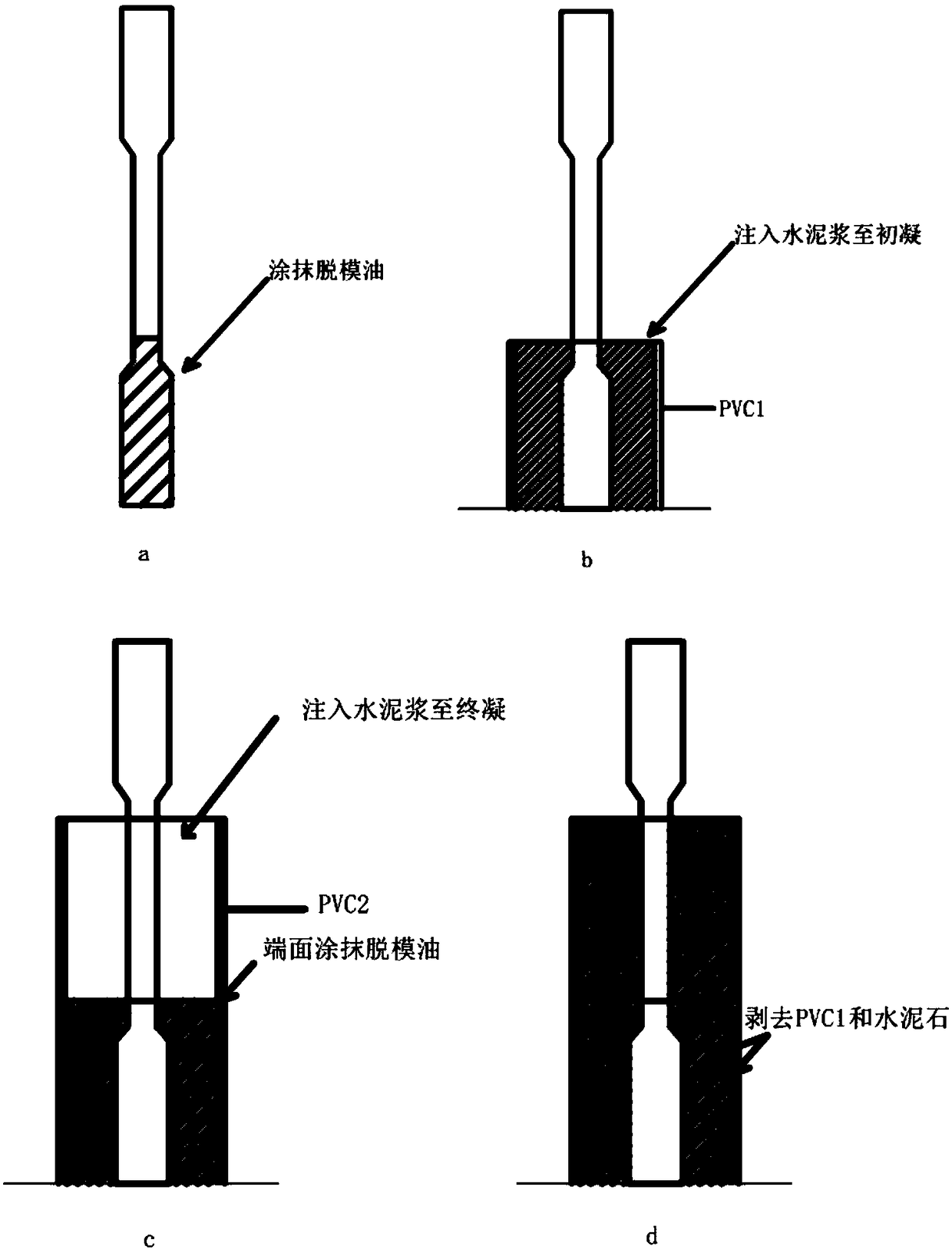

[0030] The present invention is further described below with reference to the accompanying drawings.

[0031] see figure 1 . (a): Apply mold release oil around the lower clamping end of the stretching rod to the arc connection part. (b): Put a PVC1 pipe on the lower clamping end (the diameter of the PVC1 pipe is larger than the diameter of the lower clamping end, and the height of the PVC1 pipe is slightly higher than the connection between the lower clamping end and the parallel part of the transition arc), and between the PVC1 pipe and the lower clamping end Cement slurry is injected into the annular space at the clamping end and cured at room temperature until initial setting. (c): Apply mold release oil to the exposed cement stone surface, fix the PVC2 pipe outside the parallel part, inject cement slurry into the annular space between the PVC2 pipe and the parallel part, and cure to final setting. (d): Remove the PVC1 pipe and the wrapped cement stone.

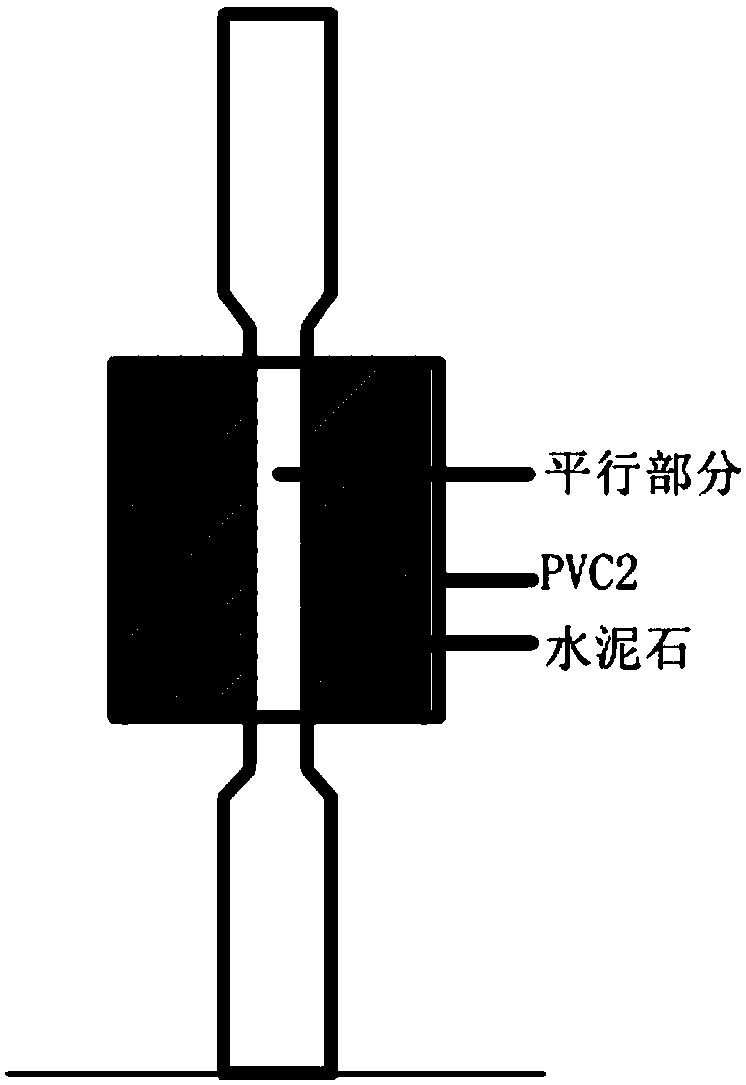

[0032] see f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com