Super black material and preparation method and application thereof

A technology of ultra-black materials and light-absorbing materials, applied in the field of ultra-black materials and their preparation, can solve the problems of inability to carry out large-scale production and high cost, and achieve the effects of low price of finished products, easy operation, and easy control of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

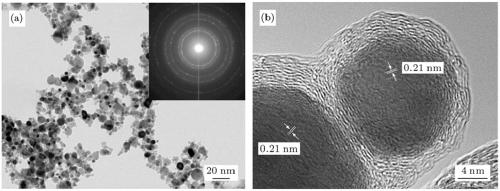

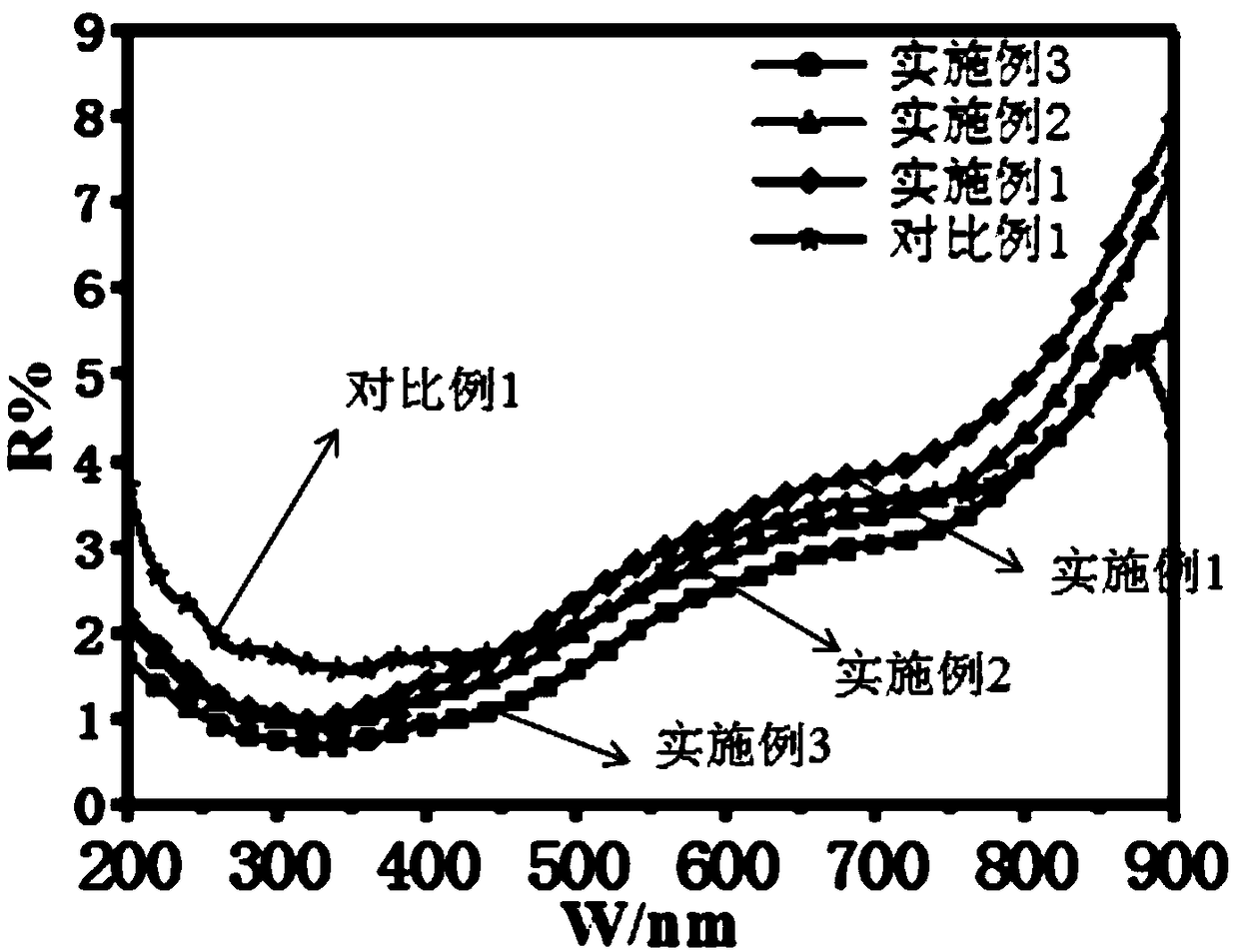

[0039] The invention provides a kind of preparation method of super black material, comprises the following steps:

[0040] (1) Place the quartz plate in alcohol, clean it with ultrasonic waves for 5 minutes, and dry it for later use;

[0041] (2) Copper acetylacetonate (Cu(acac) 2 , Aldrich Chemical Co, 97%;) placed in the quartz boat, stand-by;

[0042] (3) Place the copper acetylacetonate in the quartz boat in the evaporation zone in the tube furnace, raise the temperature to 150°C, and hold the temperature for 120min. The quartz glass plate (40mm×200mm×2mm) for collecting the samples is placed in the tube furnace. In the deposition area, the temperature is raised to 700°C, the holding time is 120min, and then the tube furnace is closed;

[0043] (4) Close all valves, turn on the vacuum pump to pump air, and after confirming that the system is airtight, set the experimental parameters, turn on the heating button, and feed the carrier gas Ar (flow rate: 200ml / min, purity: ...

Embodiment 2

[0046] The invention provides a kind of preparation method of super black material, comprises the following steps:

[0047] (1) Place the quartz plate in alcohol, clean it with ultrasonic waves for 5 minutes, and dry it for later use;

[0048] (2) Copper acetylacetonate (Cu(acac) 2 , Aldrich Chemical Co, 97%;) placed in the quartz boat, stand-by;

[0049] (3) Copper acetylacetonate in the quartz boat is placed in the evaporation zone in the tube furnace, and the temperature is raised to 150°C. The quartz glass plate (40mm×200mm×2mm) for collecting the samples is placed in the deposition zone of the tube furnace, and the temperature is raised to 150°C. 700°C, the holding time is 120min, and then the tube furnace is closed;

[0050](4) Close all valves, turn on the vacuum pump to pump air, and after confirming that the system is airtight, set the experimental parameters, turn on the heating button, and feed the carrier gas Ar (flow rate: 50ml / min, purity: 99.99%), and keep the...

Embodiment 3

[0053] The invention provides a kind of preparation method of super black material, comprises the following steps:

[0054] (1) Place the quartz plate in alcohol, clean it with ultrasonic waves for 5 minutes, and dry it for later use;

[0055] (2) Copper acetylacetonate (Cu(acac) 2 , Aldrich Chemical Co, 97%;) placed in the quartz boat, stand-by;

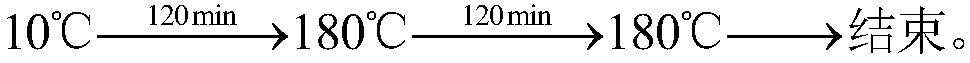

[0056] (3) Copper acetylacetonate in the quartz boat is placed in the evaporation zone in the tube furnace, and the temperature is raised to 180°C. The quartz glass plate (40mm×200mm×2mm) for collecting the samples is placed in the deposition zone of the tube furnace, and the temperature is raised to 180°C. 700°C, the holding time is 120min, and then the tube furnace is closed;

[0057] (4) Close all valves, turn on the vacuum pump to pump air, and after confirming that the system is airtight, set the experimental parameters, turn on the heating button, and feed the carrier gas Ar (flow rate: 500ml / min, purity: 99.99%), and mainta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com