Antibacterial composite cloth and method for preparing same

A fabric and composite layer technology, applied in chemical instruments and methods, alginic acid coatings, antifouling/underwater coatings, etc., can solve the problems of worsening use experience, skin allergies, stuffiness, etc. dull effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

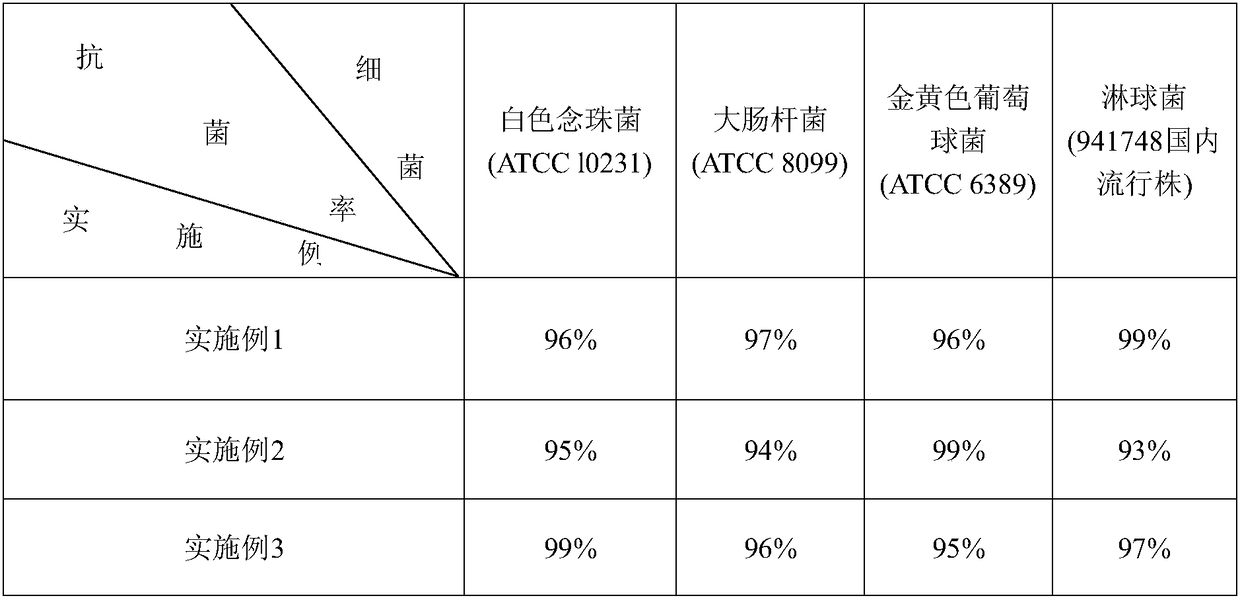

Examples

Embodiment 1

[0027] A preparation method of antibacterial composite cloth, comprising the following steps:

[0028] 1) Take polypropylene non-woven fabric as the base fabric of the outermost layer of the composite fabric, the outer surface of the base fabric is in contact with the environment, and the inner surface is sprayed with a crosslinking mixed solution of PEO and PVA, wherein the concentration of PVA (polyvinyl alcohol) is 5 %, the concentration of PEO (polyethylene oxide) is 0.2%, the mixing ratio of PEO and PVA is 0.04:1, in addition, the crosslinking agent used is maleic anhydride, wherein the amount of maleic anhydride accounts for the total mass of PEO and PVA 3.3%, the pH value of the solution is adjusted to 3 with sulfuric acid, and the coating amount of the crosslinking mixed solution is 15ml / m 2 , after coating, dry at 45°C for 15 minutes;

[0029] 2) Apply different components on both sides of the polyester non-woven fabric to prepare an antibacterial composite layer, wh...

Embodiment 2

[0032] A preparation method of antibacterial composite cloth, comprising the following steps:

[0033] 1) Take polypropylene non-woven fabric as the base cloth of the outermost layer of the composite cloth, the outer surface of the base cloth is in contact with the environment, and the inner surface is sprayed with a cross-linking mixed solution of PEO and PVA, wherein the concentration of PVA is 13%, and the concentration of PEO is 13%. The concentration is 1%, and the mixing ratio of PEO and PVA is 0.077:1. In addition, the crosslinking agent used is maleic anhydride, and the amount of maleic anhydride accounts for 5.2% of the total mass of PEO and PVA, adjusted with sulfuric acid The pH value of the solution is 4.7, and the coating amount of the crosslinking mixed solution is 45ml / m 2 , after coating, dry at 65°C for 7 minutes;

[0034] 2) Apply different components on both sides of the polyester non-woven fabric to prepare an antibacterial composite layer, wherein the upp...

Embodiment 3

[0037] A preparation method of antibacterial composite cloth, comprising the following steps:

[0038]1) Take polypropylene non-woven fabric as the base fabric of the outermost layer of the composite fabric, the outer surface of the base fabric is in contact with the environment, and the inner surface is sprayed with a cross-linking mixed solution of PEO and PVA, wherein the concentration of PVA is 8%, and the concentration of PEO is 8%. The concentration is 1.6%, and the mixing ratio of PEO and PVA is 0.2:1. In addition, the cross-linking agent used is maleic anhydride, and the amount of maleic anhydride accounts for 7.5% of the total mass of PEO and PVA, adjusted with sulfuric acid The pH value of the solution is 4.2, and the coating amount of the crosslinking mixed solution is 73ml / m 2 , after coating, dry at 60°C for 22 minutes;

[0039] 2) Apply different components on both sides of the non-woven fabric to prepare the antibacterial composite layer, wherein the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com