A kind of ytterbium-erbium co-doped phosphate glass and its preparation method and application

A phosphate glass and glass technology, which is applied in the direction of active dielectric materials, lasers, laser components, etc., can solve the problems of limiting broadband transmission applications, narrowness, etc., and achieve the effects of excellent optical performance, small transmission loss, and good glass forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

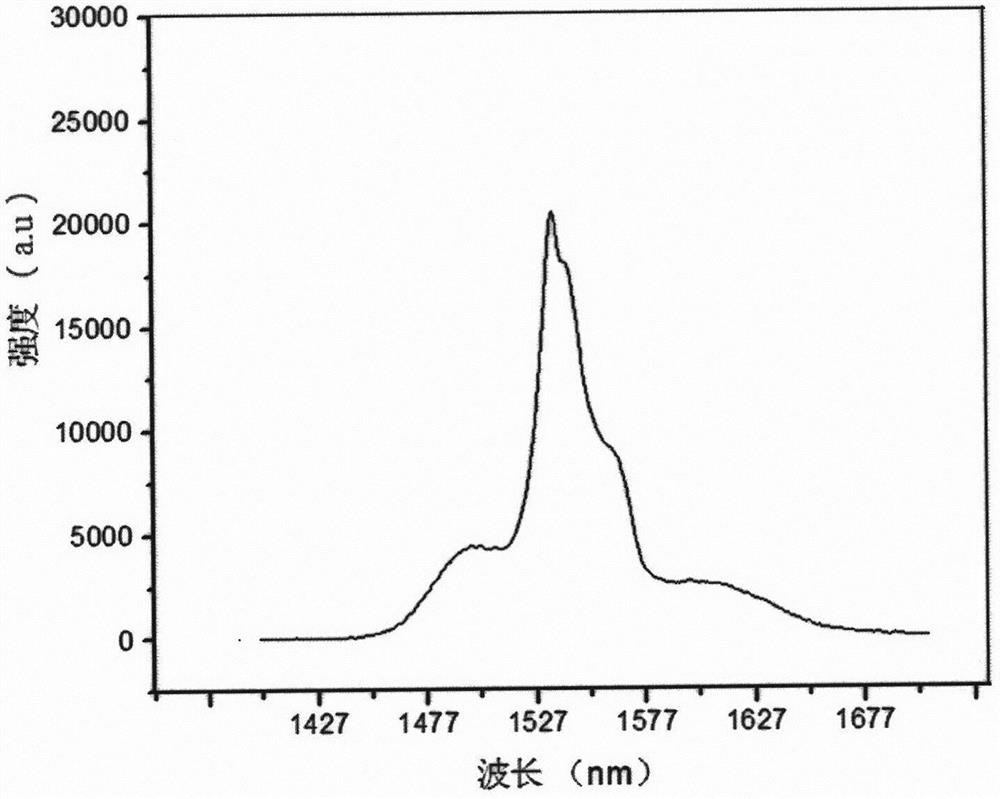

Embodiment 1

[0034] The erbium-doped phosphate glass of this embodiment.

[0035] A kind of ytterbium-erbium co-doped phosphate glass, in terms of the amount of substances, its composition ratio comprises:

[0036]

[0037] A preparation method of ytterbium-erbium co-doped phosphate glass, comprising:

[0038] (1) Ingredients

[0039] Weigh respectively 54 molar parts of ammonium dihydrogen phosphate, 29 molar parts of bismuth trioxide, 5 molar parts of antimony trioxide, 12.4 molar parts of calcium carbonate, 9 molar parts of aluminum oxide, 18 molar parts of boric acid, 9 molar parts of bismuth tellurium oxide and 0.1 molar part of erbium oxide;

[0040] (2) mixed

[0041] Mix the raw materials weighed in step (1), fully mix to obtain the mixture, and then place it in the crucible;

[0042] (3) melting

[0043] Place the crucible containing the mixture in step (2) in an electric furnace, raise it to 1100°C at a rate of 5°C / min and keep it warm for 1.5 hours to obtain molten glass...

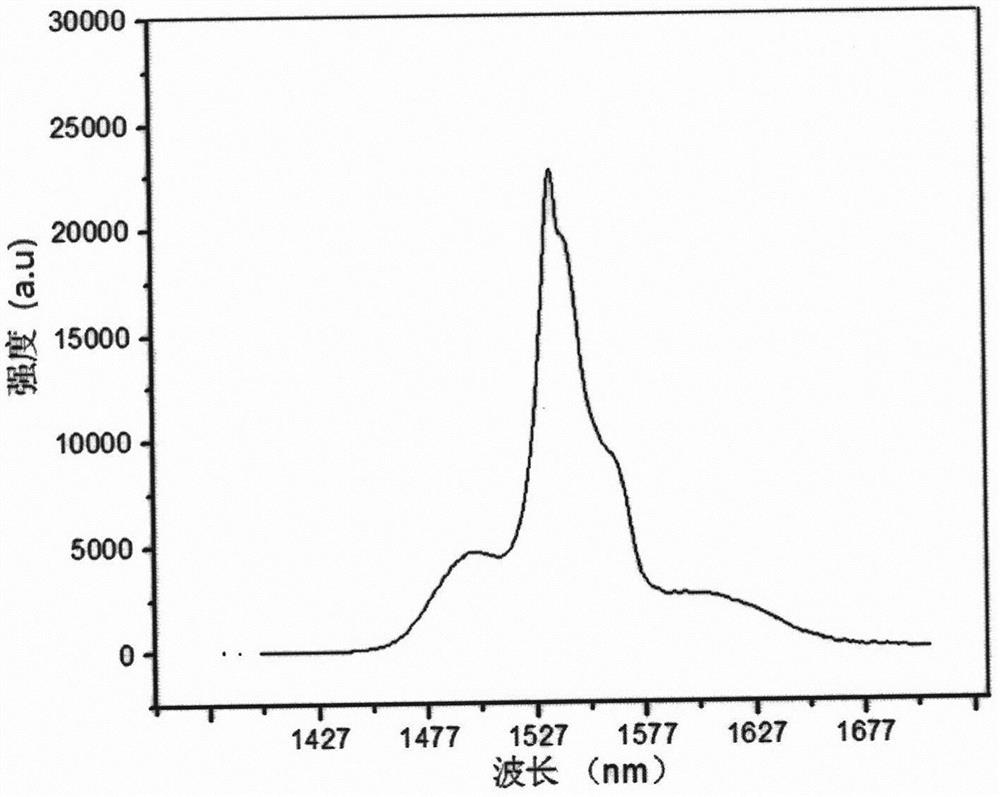

Embodiment 2

[0055] The erbium-doped phosphate glass of this embodiment.

[0056] A kind of ytterbium-erbium co-doped phosphate glass, in terms of the amount of substances, its composition ratio comprises:

[0057]

[0058] A preparation method of ytterbium-erbium co-doped phosphate glass, comprising:

[0059] (1) Ingredients

[0060] Weigh respectively 64 molar parts of ammonium dihydrogen phosphate, 26 molar parts of bismuth trioxide, 10 molar parts of antimony trioxide, 7 molar parts of calcium carbonate, 11 molar parts of aluminum oxide, 8 molar parts of boric acid, 7.5 molar parts of bismuth tellurium oxide and 0.5 mole part erbium oxide;

[0061] (2) mixed

[0062] Mix the raw materials weighed in step (1), fully mix to obtain the mixture, and then place it in the crucible;

[0063] (3) melting

[0064] Place the crucible containing the mixture in step (2) in an electric furnace, raise it to 1200°C at a rate of 10°C / min and keep it warm for 1 hour to obtain molten glass;

[00...

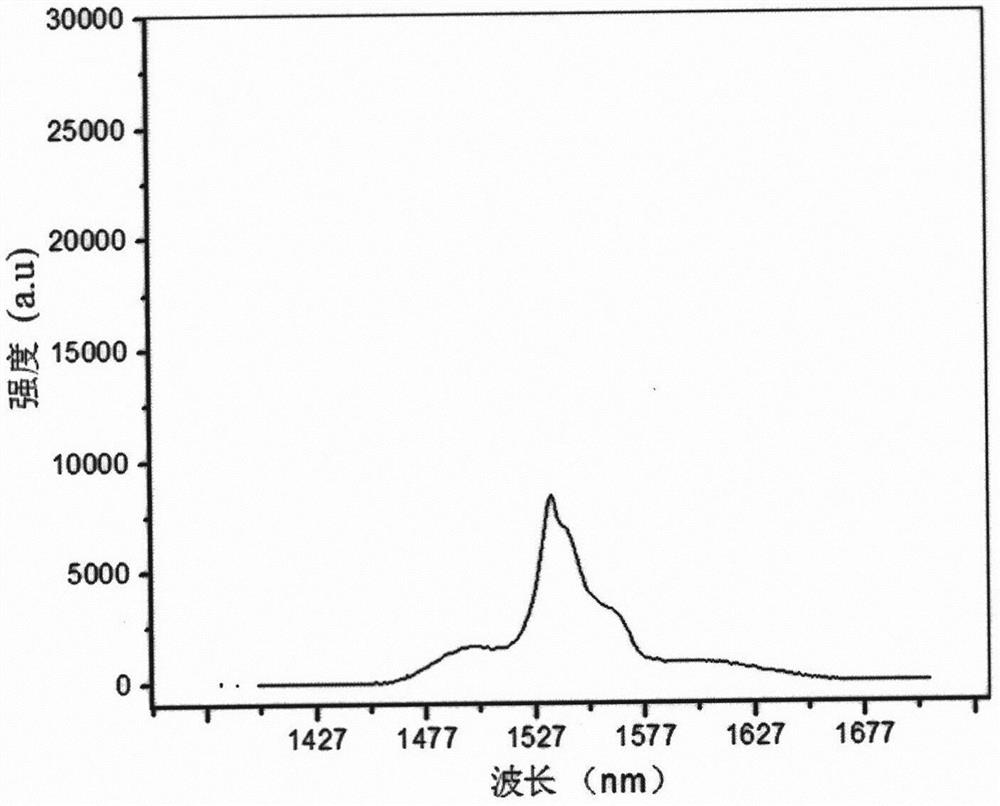

Embodiment 3

[0076] The erbium-doped phosphate glass of this embodiment.

[0077] A kind of ytterbium-erbium co-doped phosphate glass, in terms of the amount of substances, its composition ratio comprises:

[0078]

[0079] A preparation method of ytterbium-erbium co-doped phosphate glass, comprising:

[0080] (1) Ingredients

[0081] Weigh respectively 74 molar parts of ammonium dihydrogen phosphate, 17 molar parts of bismuth trioxide, 15 molar parts of antimony trioxide, 14 molar parts of calcium carbonate, 3 molar parts of aluminum oxide, 22 molar parts of boric acid, 2 molar parts of bismuth tellurium oxide and 1 molar part of erbium oxide;

[0082] (2) mixed

[0083] Mix the raw materials weighed in step (1), fully mix to obtain the mixture, and then place it in the crucible;

[0084] (3) melting

[0085] Place the crucible containing the mixture in step (2) in an electric furnace, raise it to 1150°C at a rate of 7°C / min and keep it warm for 1.25 hours to obtain molten glass; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com