Fireproof coating and preparation method thereof

A technology for fire-resistant coatings and raw materials, applied in the field of coatings, can solve the problems of low fire resistance and shortened service life, and achieve the effects of reducing temperature, good compatibility, and good fire-retardant and flame-retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

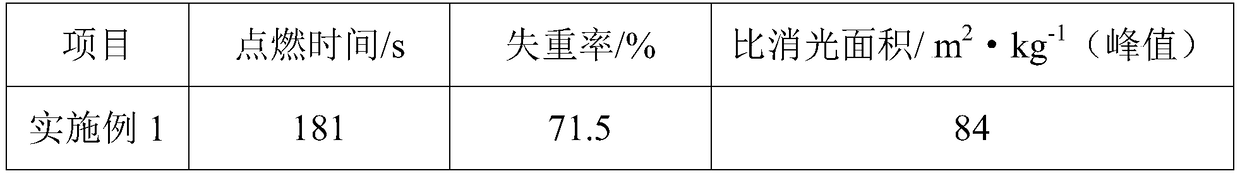

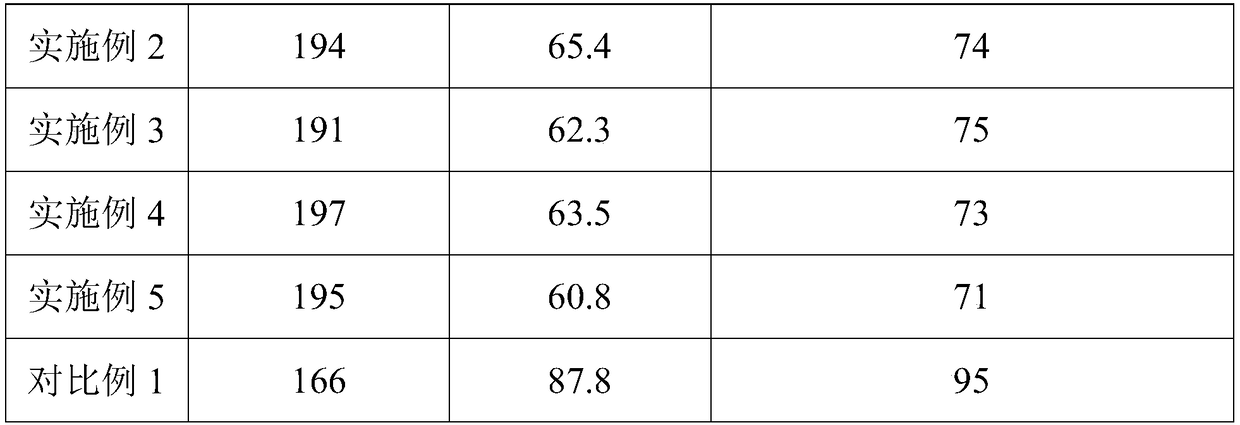

Examples

Embodiment 1

[0017] A kind of fireproof coating, its raw material comprises by weight: 33 parts of fluorocarbon resin, 16 parts of vinyl acetate resin, 6 parts of aluminum oxide powder, 9.5 parts of ammonium polyphosphate, 3 parts of iron silicon nitride powder, 17 parts of expanded graphite, fiber 1.2 parts of plain ether, 9 parts of linalool, 5.5 parts of film-forming agent, 6.9 parts of talcum powder, 3.3 parts of curing agent, and 2.5 parts of defoamer.

[0018] The preparation method of described fireproof coating, described method comprises the steps:

[0019] S1. Take ferrosilicon nitride powder and add deionized water, ultrasonically disperse to obtain a ferrosilicon nitride dispersion; add expanded graphite to the ferrosilicon nitride dispersion, mechanically stir, filter, and dry to obtain modified expanded graphite;

[0020] S2. Put fluorocarbon resin, vinyl acetate resin, alumina powder, ammonium polyphosphate, cellulose ether and linalool into the mixer in turn, stir once, the...

Embodiment 2

[0022] A kind of fireproof coating, its raw material comprises by weight: 48 parts of fluorocarbon resin, 11 parts of vinyl acetate resin, 12 parts of aluminum oxide powder, 5.5 parts of ammonium polyphosphate, 6 parts of ferrosilicon nitride powder, 9 parts of expanded graphite, fiber 5.6 parts of plain ether, 6.8 parts of linalool, 12 parts of film-forming agent, 2.3 parts of talcum powder, 5.5 parts of curing agent, and 0.5 parts of defoamer;

[0023] Wherein, the expanded graphite is composed of expanded graphite with a small particle size and expanded graphite with a large particle size in a mass ratio of 1.4:3.7.

[0024] The preparation method of described fireproof coating, described method comprises the steps:

[0025] S1. Take ferrosilicon nitride powder and add deionized water, ultrasonically disperse to obtain a ferrosilicon nitride dispersion; add expanded graphite to the ferrosilicon nitride dispersion, mechanically stir, filter, and dry to obtain modified expand...

Embodiment 3

[0028] A kind of fireproof coating, its raw material comprises by weight: 40 parts of fluorocarbon resin, 13 parts of vinyl acetate resin, 9 parts of aluminum oxide powder, 7 parts of ammonium polyphosphate, 4.5 parts of ferrosilicon nitride powder, 12 parts of expanded graphite, fiber 3 parts of plain ether, 8 parts of linalool, 9 parts of film-forming agent, 4 parts of talcum powder, 4.5 parts of curing agent, 1.5 parts of defoamer;

[0029] Wherein, the expanded graphite is composed of small particle size expanded graphite and large particle size expanded graphite according to the mass ratio of 1.5:3.5;

[0030] The expanded graphite with small particle size is 240 mesh; the expanded graphite with large particle size is 70 mesh.

[0031] The preparation method of described fireproof coating, described method comprises the steps:

[0032] S1. Take ferrosilicon nitride powder and add deionized water, ultrasonically disperse to obtain a ferrosilicon nitride dispersion; add ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com