Continuous chloride production device

A production device and technology of chlorinated substances, applied in the field of chlorinated substances production equipment, can solve problems such as difficulty in effectively improving the production of chlorinated substances, further improvement of production efficiency, and inability to realize continuous production process, so as to improve safety and environmental protection, shorten the total production cost, etc. Response time, the effect of improving intrinsic safety performance and environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

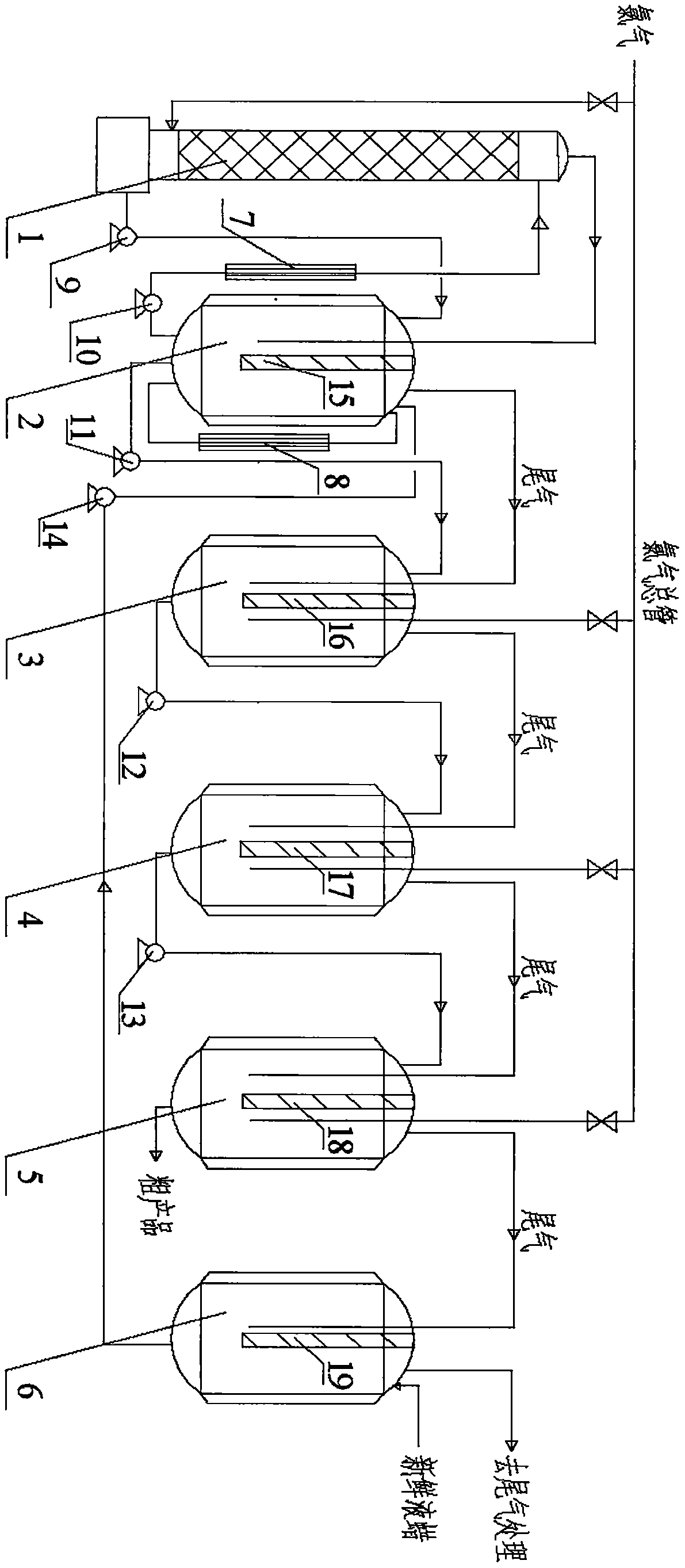

[0029] Embodiment 1: the production process device of chlorinated paraffin

[0030] Such as figure 1 As shown, the production equipment of chlorinated paraffin mainly includes absorption tower 1, reaction kettle 2, refining kettle 3, 4, 5, absorption kettle 6, heat exchanger 7, 8.

[0031] Absorption tower 1 selects glass packed tower for use, and its bottom is provided with chlorine feed inlet and chlorinated paraffin intermediate product (hereinafter referred to as " chlorine wax ") outlet, is respectively used for chlorine feed and saturated chlorine wax discharge after absorbing chlorine, chlorine The wax outlet is connected to the upper feed port of the reaction kettle 2 through the circulation pump 9; the upper part of the absorption tower 1 is provided with a chlorine wax feed inlet and a tail gas outlet, which are respectively connected with the chlorine wax outlet of the lower part of the reaction kettle 2 and the upper part of the reaction kettle. Exhaust gas inlet ...

Embodiment 2

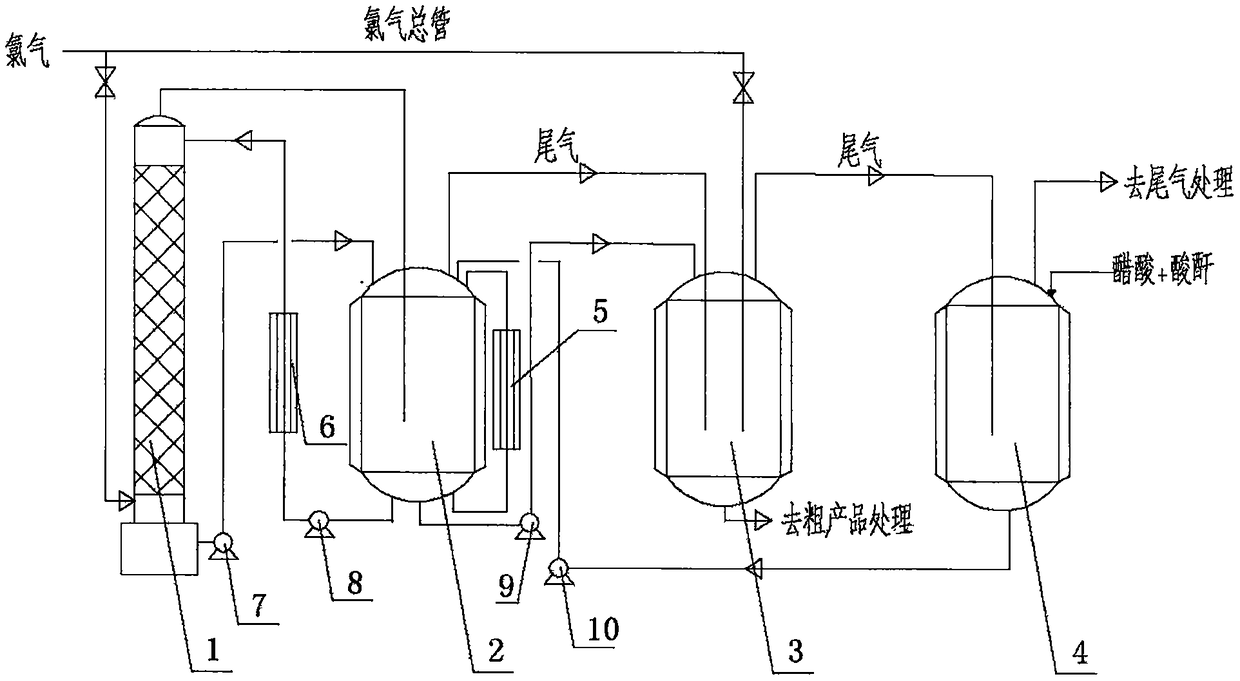

[0038] Embodiment 2: the production process device of chloroacetic acid

[0039] Such as figure 2 As shown, the production equipment of chloroacetic acid mainly includes an absorption tower 1, a reaction kettle 2, a refining kettle 3, an absorption kettle 4, heat exchangers 5, 6 and a tail gas treatment device.

[0040] The absorption tower 1 is a glass packed tower, the lower part of which is provided with a chlorine gas feed inlet and a chloroacetic acid semi-finished product outlet, which are respectively used for chlorine gas feed and chloroacetic acid semi-finished product discharge after absorbing chlorine gas saturation, and the chloroacetic acid semi-finished product outlet passes through the circulation pump 7 and reacts The upper part of the kettle 2 is connected to the feed port; the upper part of the absorption tower 1 is provided with a chloroacetic acid semi-finished product feed port and a tail gas outlet, which are respectively connected to the chloroacetic ac...

Embodiment 3

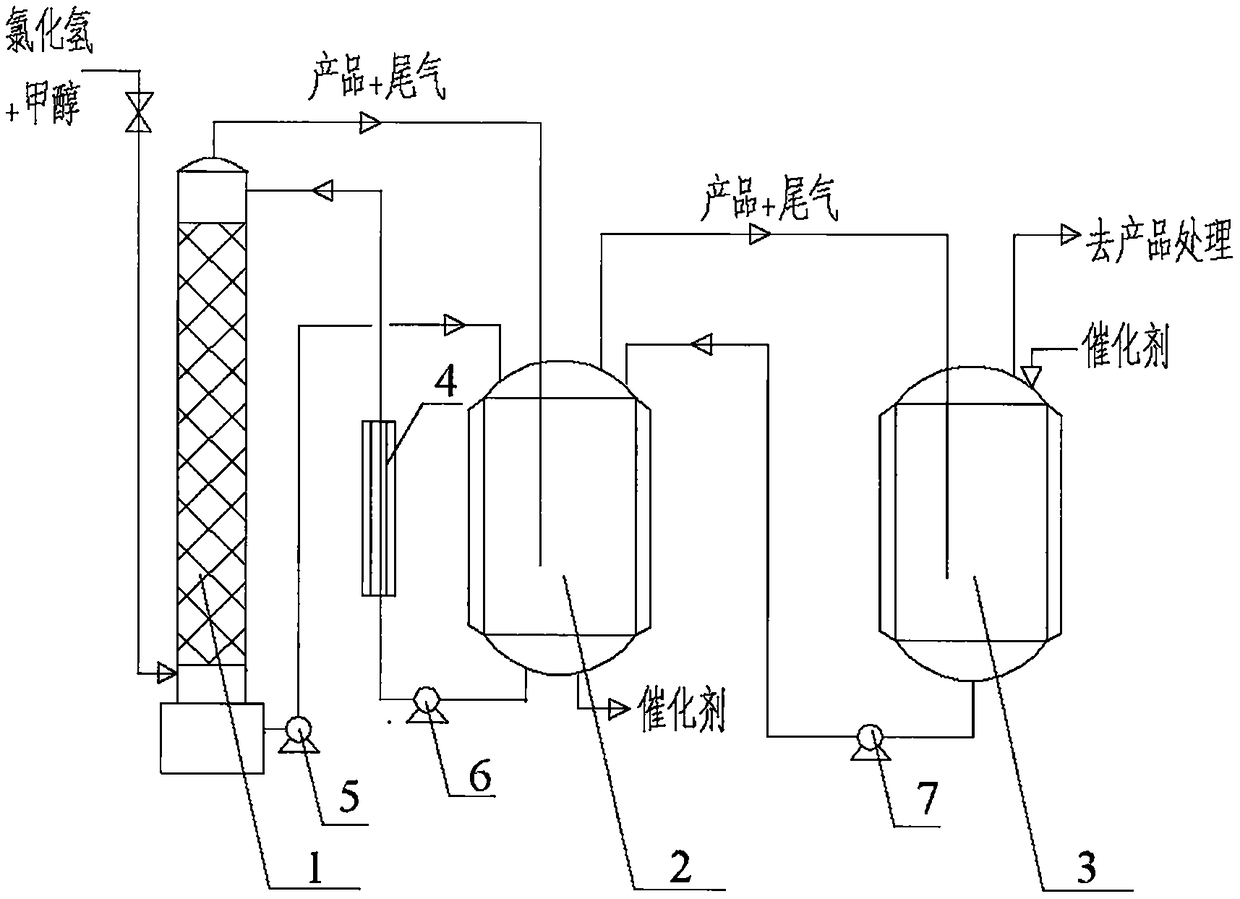

[0045] Embodiment 3: the production process device of methyl chloride

[0046] Such as image 3 As shown, the production equipment of methyl chloride mainly includes an absorption tower 1, a reaction kettle 2, an absorption kettle 3, and a heat exchanger 4.

[0047] The absorption tower 1 is a sieve plate tower, and its lower part is provided with a hydrogen chloride and methanol gas feed port and a catalyst discharge port, which are respectively used for the hydrogen chloride and methanol gas feed and the saturated catalyst discharge after absorbing the gas phase. The pump 5 is connected to the upper feed port of the reactor 2; the upper part of the absorption tower 1 is provided with a catalyst feed port and a product and tail gas outlet, which are respectively connected to the catalyst outlet of the lower part of the reactor 2 and the product and tail gas inlet of the upper part of the reactor 2.

[0048] Reactor 2 is cooled by a jacket, and its lower part is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com