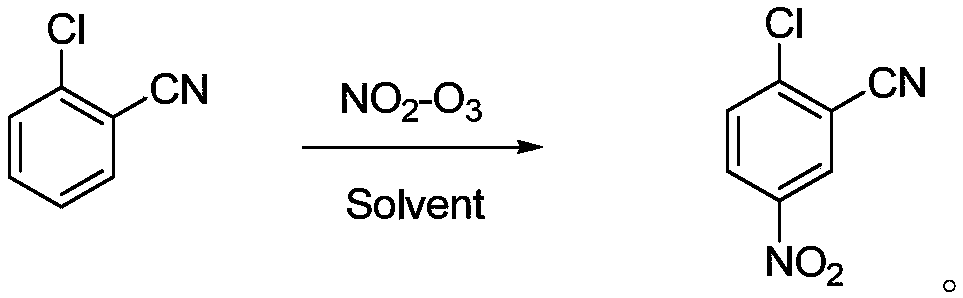

Method and device for preparing 2-chloro-5-nitrobenzonitrile in pipeline

A technology of nitrobenzonitrile and chlorobenzonitrile, which is applied in the field of tubular nitrification, can solve the problems of poor selectivity, oxidation side reactions, less corrosiveness and three waste discharges, etc., and achieves simple operation and high safety. , post-processing simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

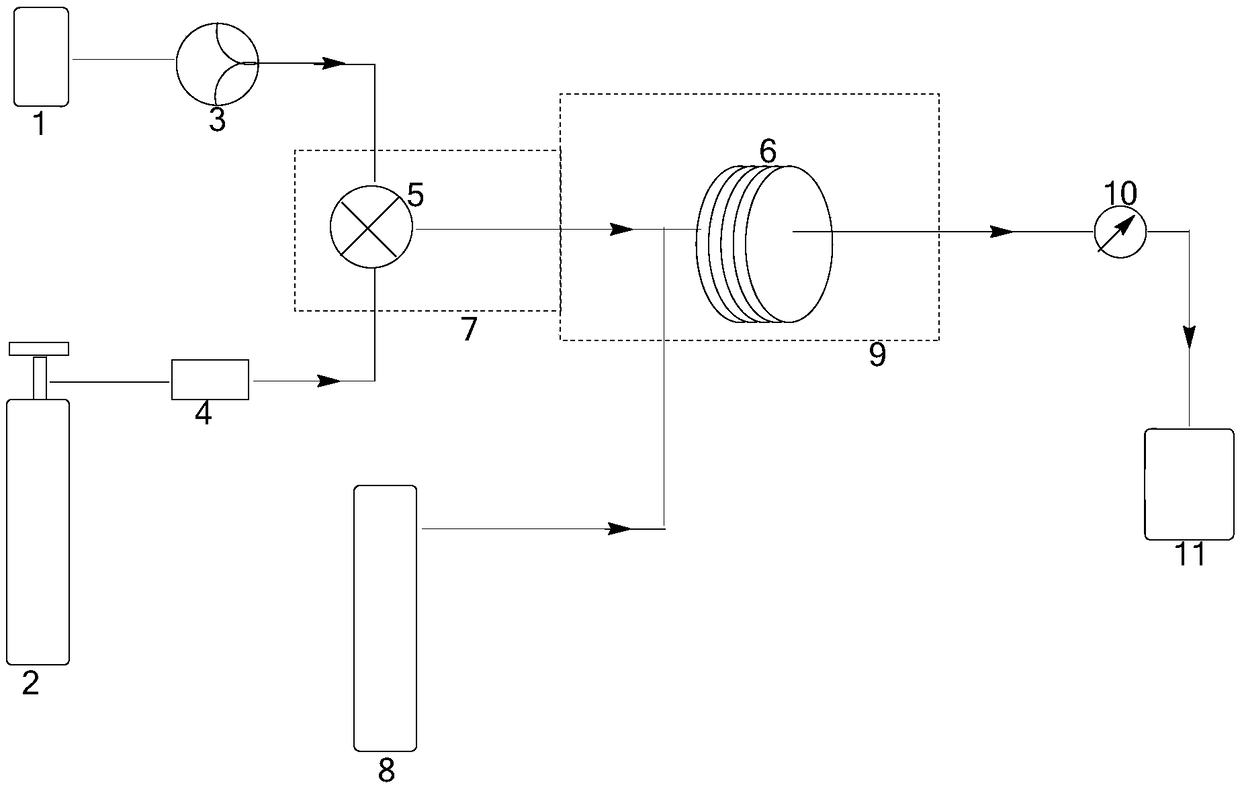

[0046] The structure of the reaction device is as figure 1 , the reaction pipeline 6 length that is filled with catalyzer is 20m, and internal diameter is 6mm, and external diameter is 8mm, and pipeline material is corrosion-resistant high-pressure metal material, is Hastelloy C-276 (Hastelloy C-276); Filled with catalyzer The catalyst in the reaction pipeline 6 is a spherical molecular sieve with a particle size of 3-5mm.

[0047] The operation steps are as follows:

[0048] First the catalyst is loaded into the reaction pipeline 6, the amount of the catalyst is based on filling the pipeline, and the two ends of the pipeline are sealed with a screen to prevent the catalyst from flowing out with the reaction solution, connect the device, and check the tightness; the raw material 2-chlorobenzyl Nitrile is dissolved in the methylene chloride organic solvent, and its volumetric dosage is 5mL / g based on the mass of the raw material 2-chlorobenzonitrile, and is added to the storag...

Embodiment 2

[0050] The structure of the reaction device is as figure 1 , the reaction pipeline 6 length that is filled with catalyzer is 25m, and inner diameter is 6mm, and outer diameter is 8mm, and pipeline material is corrosion-resistant high-pressure metal material, is Hastelloy C-276; The catalyzer in the reaction pipeline 6 that is filled with catalyzer Silica gel particles with a particle size of 3-5mm.

[0051] The volume consumption of the organic solvent is 6mL / g based on the mass of the raw material 2-chlorobenzonitrile, and the reaction pipeline 6 filled with the catalyst is preheated until the reaction temperature is 40°C; the pressure in the reaction pipeline 6 is maintained at 0.6MPa; The molar ratio of 2-chlorobenzonitrile to nitrogen dioxide was 1:1.5; the residence time of the nitration reaction was 40 min; the others were the same as in Example 1, and the product was obtained after post-treatment with a yield of 87% and an HPLC purity of 99.0%.

Embodiment 3

[0053] The structure of the reaction device is as figure 1 , the reaction pipeline 6 length that is filled with catalyzer is 30m, and inner diameter is 6mm, and outer diameter is 8mm, and pipeline material is corrosion-resistant high-pressure metal material, is Hastelloy C-276; The catalyzer in the reaction pipeline 6 that is filled with catalyzer It is a spherical molecular sieve with a particle size of 3-5mm.

[0054] The volume consumption of the organic solvent is 8mL / g based on the mass of the raw material 2-chlorobenzonitrile, and the reaction pipeline 6 filled with the catalyst is preheated to a reaction temperature of 30°C; the pressure in the reaction pipeline 6 is maintained at 0.8MPa; The molar ratio of 2-chlorobenzonitrile to nitrogen dioxide was 1:1.8; the residence time of the nitration reaction was 35 min; the others were the same as in Example 1, and the product was obtained after post-treatment with a yield of 85% and an HPLC purity of 99.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com