Method for extracting kaempferol galactoside compounds from Nanshan tea

A technology of galactoside and kaempferol, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve problems such as insufficient research, and achieve the effect of simple extraction method and high extraction purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

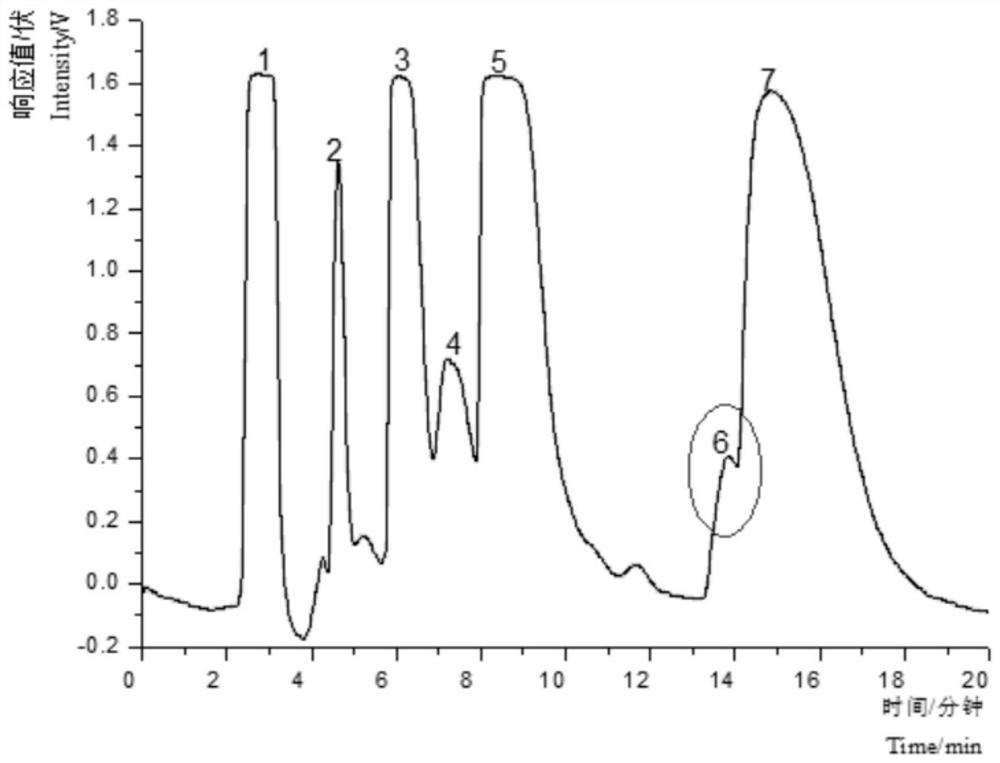

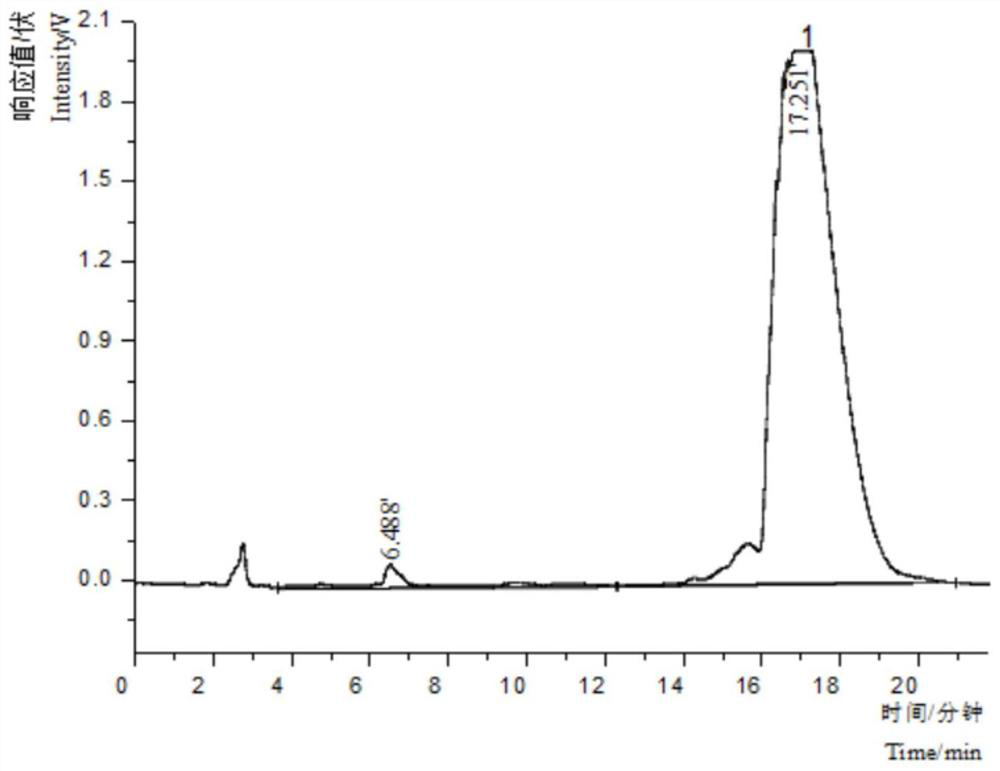

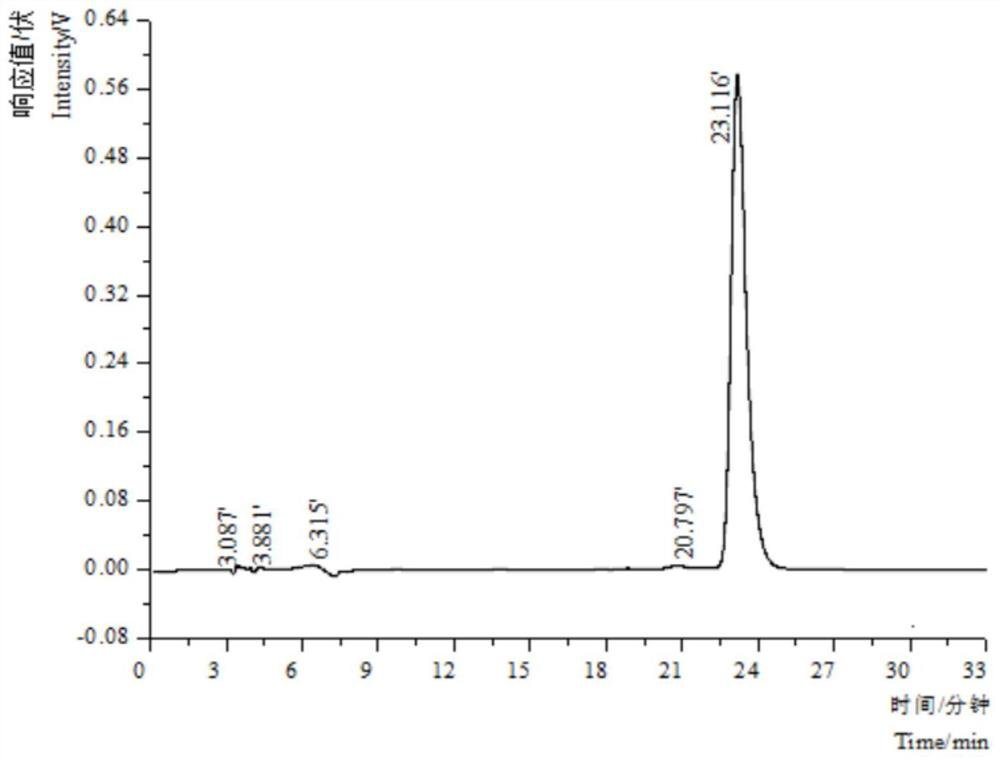

Method used

Image

Examples

Embodiment 1

[0047] The tea fruit of Nanshan tea is dried in the air, the shell is removed, and the cake produced after the oil is removed by physical pressing is dried in the air, and properly crushed to obtain Nanshan tea tea cake. Ultrasonic extraction with 50% ethanol aqueous solution at 60°C for 3 times, 2 hours each time, with a solid-liquid ratio of 1:4 (m / v), and then filtered and combined to obtain the extract. Then the extract was concentrated, extracted with an equal volume of n-butanol to obtain an extract, and then diluted 20 times with water to obtain a sample liquid.

[0048] Shelling and degreasing are to maximize the extraction yield and reduce interference during the separation process. Appropriate raw material handling methods are also beneficial to avoid the loss of target compounds.

[0049] Choose the model of macroporous resin to be D101 type, first soak D101 macroporous resin with ethanol, then pack column (column volume BV 1 10L), rinse with ethanol and water in ...

Embodiment 2

[0055] The tea fruit of Nanshan tea is dried in the air, the shell is removed, and the cake produced after the oil is removed by physical pressing is dried in the air, and properly crushed to obtain Nanshan tea tea cake. Ultrasonic leaching with 60% ethanol aqueous solution at 70°C twice, each time for 2 hours, with a solid-liquid ratio of 1:2 (m / v), then filtered and combined to obtain the extract. Then the extract was concentrated, extracted with an equal volume of n-butanol to obtain an extract, and then diluted 22 times with water to obtain a sample liquid.

[0056] Choose the model of macroporous resin to be D101 type, first soak D101 macroporous resin with ethanol, then pack column (column volume BV 1 10L), rinse with ethanol and water in turn until there is no ethanol smell, and it can be detected with an alcohol meter, and the reading is less than 5. Slowly add the sample solution into the macroporous resin chromatography column, and then sequentially use 6 times of B...

Embodiment 3

[0061] The tea fruit of Nanshan tea is dried in the air, the shell is removed, and the cake produced after the oil is removed by physical pressing is dried in the air, and properly crushed to obtain Nanshan tea tea cake. Ultrasonic leaching with 55% ethanol aqueous solution at 65°C for 4 times, 2 hours each time, with a solid-liquid ratio of 1:4 (m / v), then filtered and combined to obtain the extract. Then the extract was concentrated, extracted with an equal volume of n-butanol to obtain an extract, and then diluted 18 times with water to obtain a sample liquid.

[0062] Choose the model of macroporous resin to be D101 type, first soak D101 macroporous resin with ethanol, then pack column (column volume BV 1 10L), rinse with ethanol and water in turn until there is no ethanol smell, and it can be detected with an alcohol meter, and the reading is less than 5. Slowly add the sample solution into the macroporous resin chromatography column, and then sequentially use 6 times of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com