Preparation method of polyvinyl alcohol/silicon dioxide microporous foaming material

A technology of microcellular foaming material and polyvinyl alcohol, which is applied in the field of preparation of polyvinyl alcohol/silicon dioxide microcellular foaming material, can solve the problem of comprehensive mechanical properties lower than expected, low solubility of carbon dioxide, and weak melt Strength and other issues, to achieve the effect of increasing the cell nucleation rate, superior mechanical properties, and reducing the free energy barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

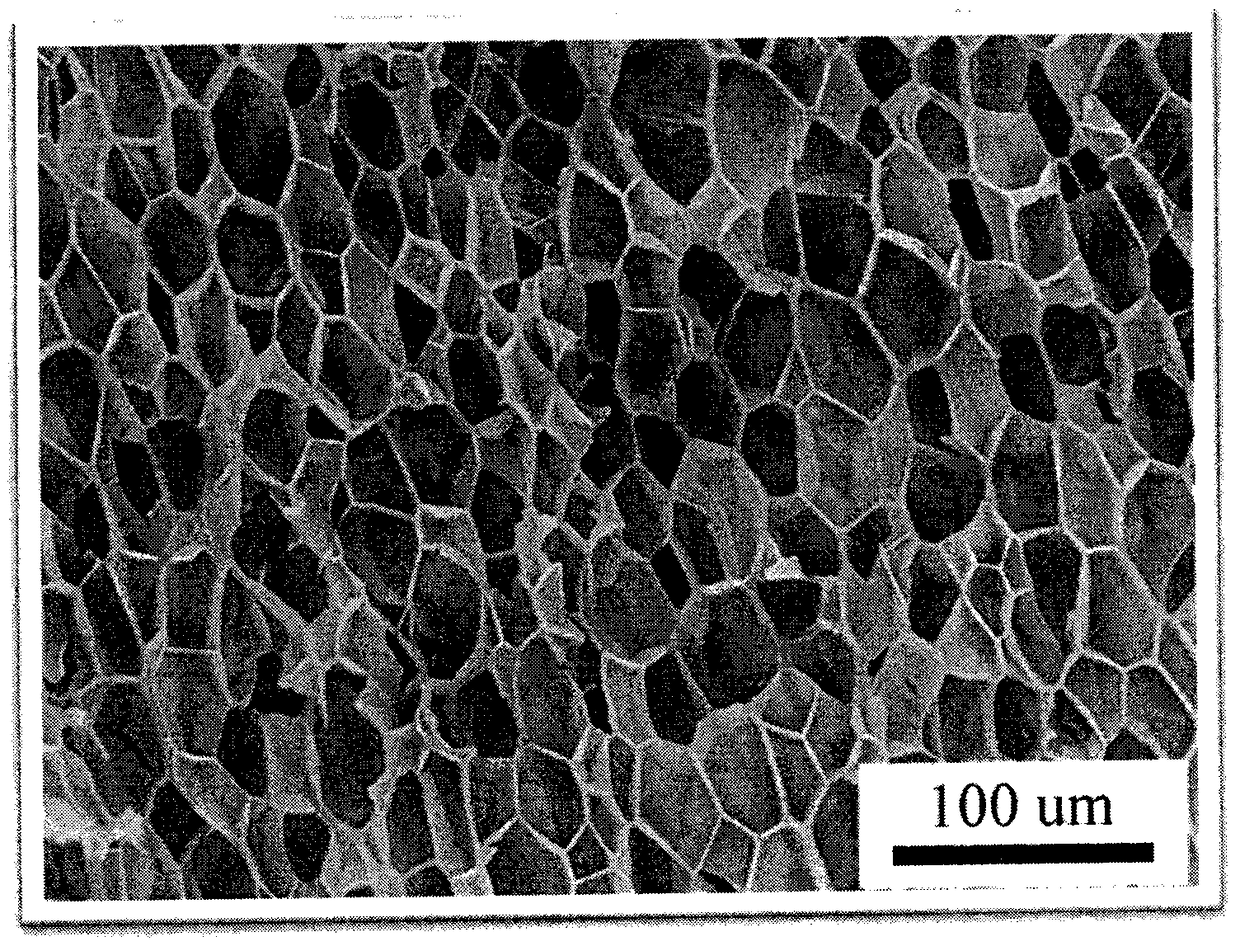

[0015] The present invention relates to a preparation method of polyvinyl alcohol / silicon dioxide microporous foam material, comprising step 1, step 2 and step 3;

[0016] Step 1: Preparation of silica containing polar groups, the polar groups being one or more of hydroxyl, amino and epoxy groups;

[0017] Step 2: Preparation of polyvinyl alcohol composition, polyvinyl alcohol composition comprises polyvinyl alcohol, polar group-containing silicon dioxide and plasticizer prepared in step 1, and the polyvinyl alcohol in the polyvinyl alcohol composition is For 100 parts by mass, the polar group-containing silicon dioxide is 0.1-5.0 parts by mass, and the plasticizer is 5-30 parts by mass;

[0018] Step 3: Place the polyvinyl alcohol composition in a high-pressure mold, raise the temperature to the saturation temperature, the saturation temperature is 130°C-165°C, fill the supercritical fluid to the saturation pressure, the saturation pressure is 10-18MPa, keep the temperature a...

Embodiment 1

[0067] Put 120mL of ethanol and 9.6mL of ammonia water in a 250mL round bottom flask and stir for 15min to form a uniform solution, then add 10mL of tetraethoxysilane into the mixed solution. Stir at room temperature. After 15 to 20 minutes, the solution starts to turn from clear to turbid and milky white. After 12 hours, the mixed solution is centrifuged, washed once with distilled water, and washed three times with ethanol. Finally, the product was vacuum-dried at 60° C. for 12 h to obtain hydroxyl-containing silica.

[0068] The plasticizer is obtained by mixing glycerin and pentylene glycol in a ratio of 1:1, dispersing 1 g of hydroxyl-containing silicon dioxide in 14 g of plasticizer, stirring ultrasonically, and then adding 85 g of polyvinyl alcohol powder (PVA1799, alcohol The degree of solution is 99%, Hengrui Chemical Industry) was added therein, and stirred vigorously at 60° C. for 1 h to obtain a polyvinyl alcohol composition. A sheet of polyvinyl alcohol compositi...

Embodiment 2

[0073] Using 500mL of ethanol and 500mL of distilled water as a mixed solvent, add 2g of the hydroxyl-containing silica prepared in Example 1 to the above mixed solvent and ultrasonically disperse it evenly, then add 2.5mL of 3-aminopropyl trimethyl Oxysilane and 10 mL of ammonia water were mechanically stirred at room temperature for 12 hours, and then the mixed solution was centrifuged, and the obtained precipitate was washed 5 times with distilled water and absolute ethanol, and finally the product was vacuum-dried at 60°C to obtain amino group-containing silica.

[0074] The plasticizer is obtained by mixing glycerin and pentylene glycol in a ratio of 1:1, dispersing 1 g of amino-containing silicon dioxide in 14 g of plasticizer, stirring ultrasonically, and then adding 85 g of polyvinyl alcohol powder (PVA1799, alcohol The degree of solution is 99%, Hengrui Chemical Industry) was added therein, and stirred vigorously at 60° C. for 1 h to obtain a polyvinyl alcohol composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com