A kind of polyurethane adhesive and preparation method thereof

A technology of polyurethane adhesive and coupling agent, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of low bonding strength, unstable quality, endangering the health of consumers, etc. Achieve good peel strength, overcome quality instability, and reduce processing and coating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

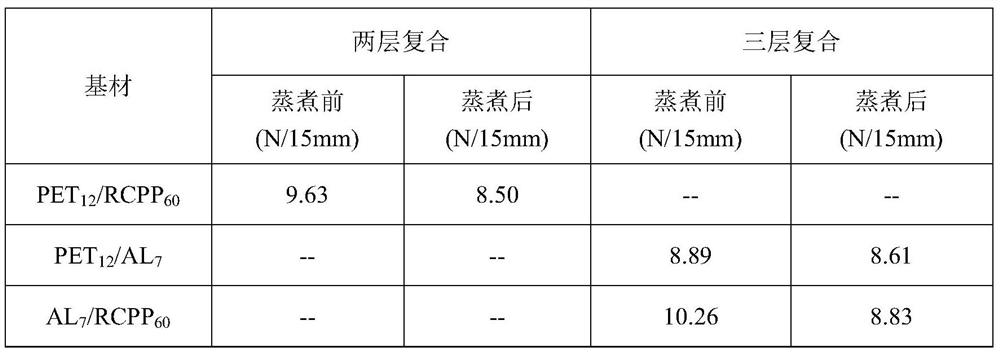

Embodiment 1

[0047] The polyurethane adhesive provided in this embodiment includes component A and component B, wherein component A is a polyurethane prepolymer terminated by isocyanate groups, component B is a polyol compound terminated by hydroxyl groups, and in component A, the isocyanate group and the group The molar ratio of hydroxyl groups in Part B is 1.7:1, where:

[0048] Component A is mainly made of the following raw materials in parts by mass:

[0049] Oligomer resin a: 60

[0050] Polyisocyanate: 105

[0051] oligomer polyol: 20;

[0052] Component B is mainly made of the following raw materials in parts by mass:

[0053] Oligomer resin b: 150

[0054] Polyisocyanate: 5.5

[0055] Hyperbranched polymer: 5.0

[0056] Nanomaterials: 0.5

[0057] Coupling agent: 1.0

[0058] Defoamer: 0.2

[0059] Leveling agent: 0.05;

[0060] Wherein the oligomer resin a and oligomer resin b are prepared by reacting small molecular polybasic acid and small molecular polyol through pol...

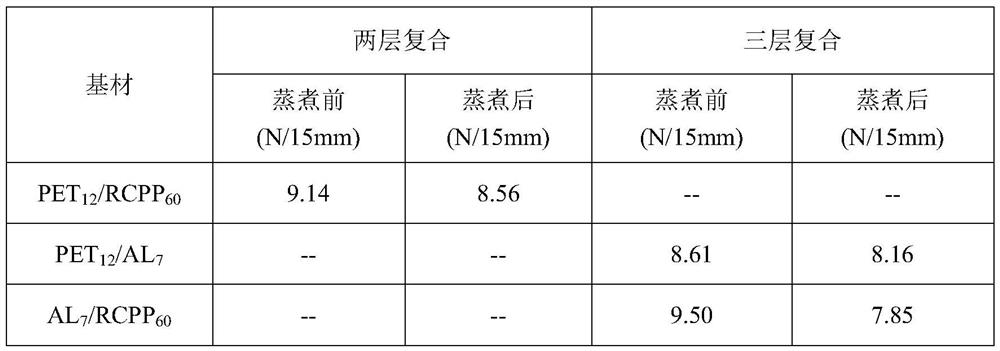

Embodiment 2

[0078] The polyurethane adhesive provided in this embodiment includes component A and component B, wherein component A is a polyurethane prepolymer terminated by isocyanate groups, component B is a polyol compound terminated by hydroxyl groups, and in component A, the isocyanate group and the group The molar ratio of hydroxyl groups in Part B is 1.9:1, where:

[0079] Component A is mainly made of the following raw materials in parts by mass:

[0080] Oligomer resin a: 70

[0081] Polyisocyanate: 85

[0082] oligomer polyol: 25;

[0083] Component B is mainly made of the following raw materials in parts by mass:

[0084] Oligomer resin b: 130

[0085] Polyisocyanate: 10

[0086] Hyperbranched polymer: 4.0

[0087] Nanomaterials: 0.7

[0088] Coupling agent: 0.8

[0089] Defoamer: 0.4

[0090] Leveling agent: 0.1;

[0091] Wherein the oligomer resin a and oligomer resin b are prepared by reacting small molecular polybasic acid and small molecular polyol through polyes...

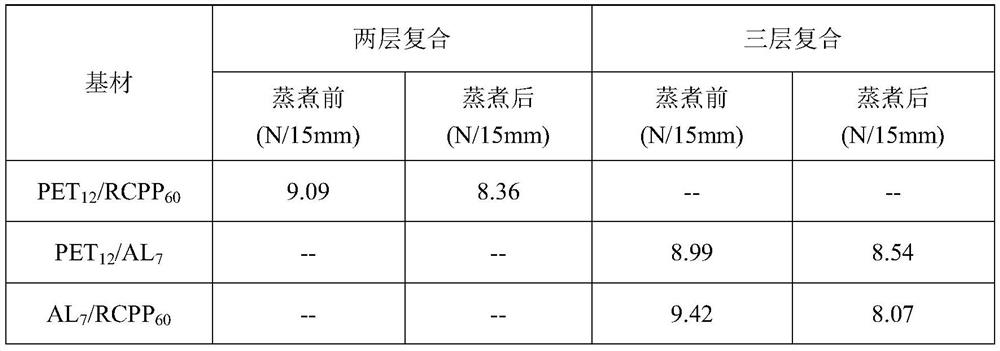

Embodiment 3

[0107] The polyurethane adhesive provided in this embodiment includes component A and component B, wherein component A is a polyurethane prepolymer terminated by isocyanate groups, component B is a polyol compound terminated by hydroxyl groups, and in component A, the isocyanate group and the group The molar ratio of hydroxyl groups in Part B is 2.0:1, where:

[0108] Component A is mainly made of the following raw materials in parts by mass:

[0109] Oligomer resin a: 80

[0110] Polyisocyanate: 135

[0111] oligomer polyol: 25;

[0112] Component B is mainly made of the following raw materials in parts by mass:

[0113] Oligomer resin b: 140

[0114] Polyisocyanate: 7

[0115] Hyperbranched polymer: 3.0

[0116] Nanomaterials: 0.8

[0117] Coupling agent: 0.7

[0118] Defoamer: 00.5

[0119] Leveling agent: 0.2;

[0120] Wherein the oligomer resin a and oligomer resin b are prepared by reacting small molecular polybasic acid and small molecular polyol through polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com