Co-culture method for improving acid resistant ability of saccharomycetes

A yeast and co-cultivation technology, applied in the field of bioengineering, can solve the problems of cell growth and metabolism inhibition, affecting food production efficiency, etc., and achieve the effects of improving growth performance, good growth performance, and improving acid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

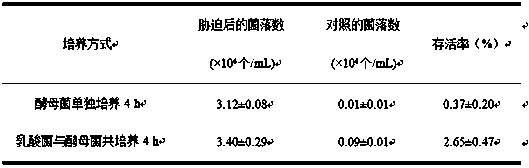

[0014] Example 1: Yeast ( Zygosaccharomyces rouxii ) CGMCC3791 was cultured alone (control group), and after acid stress treatment, the number of yeast colonies counted on the yeast extract peptone glucose agar medium was used to calculate the survival rate ( figure 1 ).

[0015] Take the storage solution of yeast stored at -80°C in glycerol tubes, inoculate 20% of the inoculum into 5 mL of yeast culture medium, culture at 30°C for 24 hours, and transfer to 100 mL of yeast at 5% of the inoculum culture medium at 30°C for 24 hours. The seed solution was centrifuged at 10,000 rpm (4°C) for 5 min to collect the bacteria, resuspended in 4 mL of sterile water, and 0.5 mL of it was inoculated into 30 mL of co-cultivation medium, and cultured at 30°C for 4 h. Take 2 mL of the culture solution in three 5 mL EP tubes, centrifuge at 10,000 rpm (4°C) for 5 min, discard the supernatant, and then add 4 mL of lactic acid to adjust the pH to 5.4 (co-cultivation medium pH) and 1.9 normal...

example 2

[0016] Example 2: Lactic acid bacteria ( Tetragenococcus shalophilus ) CGMCC 3792 was cultured for 4 h in advance, and then mixed with yeast ( Zygosaccharomyces rouxii ) CGMCC3791 co-cultivated for 4 h (experimental group), after acid stress treatment, the number of yeast colonies counted on the yeast extract peptone glucose agar medium (added with 0.01% chloramphenicol), and the survival rate was calculated ( figure 1 ).

[0017] The storage solutions of lactic acid bacteria and yeast stored in glycerol tubes at -80°C were respectively taken, and inoculated into 5 mL of lactic acid bacteria medium and yeast medium at an inoculum volume of 20%, cultured at 30°C for 24 hours, and then inoculated with 5% The inoculum was transferred to 100 mL of lactic acid bacteria medium and yeast medium, and cultured at 30°C for 24 h. The two culture solutions were centrifuged at 10,000 rpm (4°C) for 5 min to collect the bacteria, resuspended in 4 mL of sterile water, and 0.5 mL of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com