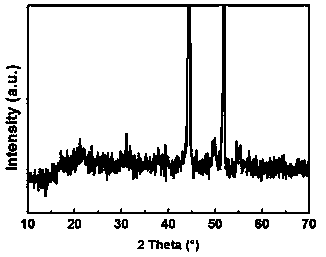

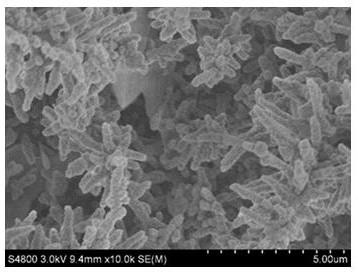

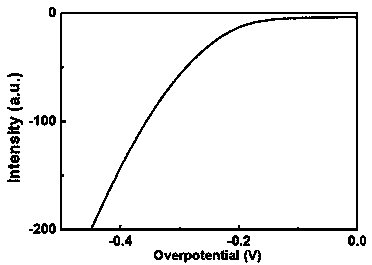

V-doped Ni3S2/NF electrode material with short rods self-assembled into dendritic shape and preparation method thereof

An electrode material and self-assembly technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the problems of high price, limited large-scale use, and scarce reserves, etc., to improve catalytic activity, not easy to agglomerate, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) The conductive substrate was immersed in acetone solution for ultrasonic cleaning for 10 minutes, then transferred to 2 mol / L hydrochloric acid for ultrasonic cleaning for 10 minutes, and finally rinsed alternately with ethanol and ultrapure water for 3 times, and then vacuum-dried at 35 °C for 10 hours;

[0019] (2) Prepare a precursor solution, which contains nickel chloride hexahydrate with a concentration of 0.05mol / L, vanadium chloride with a concentration of 0.0125mol / L, ammonium fluoride with a concentration of 0.05mol / L and a concentration of 0.05mol / L. 0.125) mol / L urea aqueous solution, magnetic stirring at room temperature for 20min to obtain clear solution A. Transfer the clear solution A and the conductive substrate treated in step (1) into a high-temperature and high-pressure hydrothermal kettle, and then react at 100 ° C for 18 hours, in which the reaction filling ratio should be controlled at 40%. After the hydrothermal reaction was over, the reactio...

Embodiment 2

[0022] (1) Immerse 1cm x 5cm nickel foam in acetone solution for ultrasonic cleaning for 10 minutes, then transfer to 2mol / L hydrochloric acid for ultrasonic cleaning for 10 minutes, and finally rinse with ethanol and ultrapure water alternately for 3 times, and then at 35 °C Vacuum drying for 10h;

[0023] (2) Prepare a precursor solution, which contains nickel chloride hexahydrate with a concentration of 0.1 mol / L, vanadium chloride with a concentration of 0.04 mol / L, ammonium fluoride with a concentration of 0.05 mol / L and a concentration of 0.05 mol / L. It is an aqueous solution of 0.2 mol / L urea, which is magnetically stirred for 20 min at room temperature to obtain a clear solution A. Transfer the clear solution A and the conductive substrate treated in step (1) into a high-temperature and high-pressure hydrothermal kettle, and then react at 120 ° C for 14 hours, in which the reaction filling ratio should be controlled at 40%. After the hydrothermal reaction was over, th...

Embodiment 3

[0026] (1) Immerse the nickel foam of 1cm x 5cm in acetone solution for ultrasonic cleaning for 5 minutes, then immerse the nickel foam in 2mol / L hydrochloric acid for ultrasonic cleaning for 5 minutes, and finally rinse with ethanol and ultrapure water alternately for 3 times. After vacuum drying at ℃ for 10, the treated nickel foam was obtained;

[0027] (2) Prepare a precursor solution, which contains nickel chloride hexahydrate with a concentration of 0.1 mol / L, vanadium chloride with a concentration of 0.05 mol / L, ammonium fluoride with a concentration of 0.05 mol / L and a concentration of 0.05 mol / L. It is an aqueous solution of 0.2 mol / L urea, which is magnetically stirred for 20 min at room temperature to obtain a clear solution A. Transfer the clear solution A and the nickel foam treated in step (1) into a high-temperature and high-pressure hydrothermal kettle, and then react at 140 ° C for 10 hours, in which the reaction filling ratio should be controlled at 30%. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com