Method for measuring ingot casting temperature distribution in electroslag remelting process

A technology of temperature distribution and electroslag remelting, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of incomplete mechanism research, poor versatility, and imperfect theoretical research, etc., and meet the requirements of measuring equipment and equipment transformation Low, easy to popularize, reduce the difficulty of solving and the effect of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

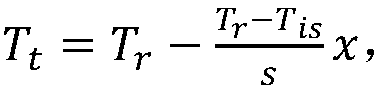

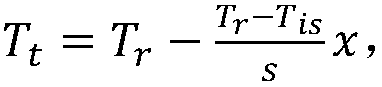

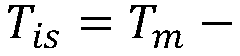

[0048] Taking H13 smelted by electroslag remelting as an example, the ingot diameter is 1.2m. Use 10000A current and 50Hz alternating current for smelting. When electroslag remelting takes 6000s, put in 100g FeS, and record the wall temperature and bottom temperature at this temperature, and calculate the surface temperature of the ingot on the cooling surface of the crystallizer and the bottom water tank through relevant formulas. The surface temperature of the ingot on the cooling surface, in which Table 1 is the surface temperature of the ingot on the cooling surface of the mold, Table 2 is the surface temperature of the ingot on the cooling surface of the bottom water tank, Table 3 to Table 5 are the temperature along the transverse direction under different axial coordinates Ingot temperature distribution.

[0049] Table 1 Ingot Surface Temperature of Cooling Surface of Mold

[0050] X / m

[0051] Table 2 Ingot Surface Temperature of Cooling Surface of Bottom Wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com