Method for preparing fresh dechlorination agent from waste dechlorination agent

A technology of waste dechlorination agent and dechlorination agent, which is applied in separation methods, solid waste removal, combustible gas purification/reconstruction, etc., can solve the problems of high input cost and poor economic benefits, achieve high economic value and avoid waste. , the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

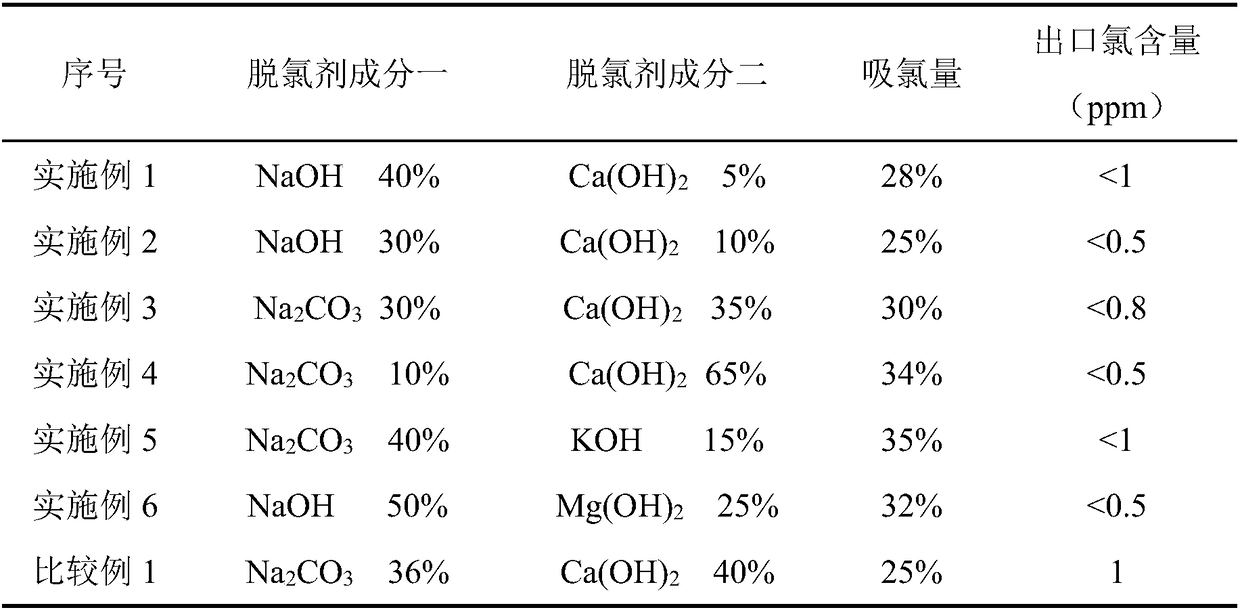

Examples

Embodiment 1

[0022] Take by weighing 100g waste dechlorination agent, this waste dechlorination agent is to be applied to the waste dechlorination agent of removing hydrogen chloride in the regeneration gas of catalytic reforming unit, its component is NaOH 20%, Ca(OH) 2 5%, NaCl 20%, and the rest is clay; after pulverizing the waste dechlorination agent, add 100ml of water, stir and filter, and dry the solid residue for later use; the filtered solution is passed through the polystyrene series strong basic anion Exchange resin bed, exchange with hydroxide ions and absorb chloride ions, evaporate part of the water in the lye, the moisture content in the lye is 53%, add solid slag and 15g methyl cellulose, knead evenly on the kneader, knead The finished material is extruded on the extruder, dried and roasted to obtain the regenerated fresh dechlorination agent. The roasting temperature is 400°C and the roasting time is 10 hours.

[0023] The present embodiment obtains the fresh dechlorinatio...

Embodiment 2

[0026] Take by weighing 80g waste dechlorination agent, this waste dechlorination agent is to be applied to the waste dechlorination agent that removes hydrogen chloride in the regeneration gas of catalytic reforming unit, and its component is Na 2 O 20%, CaO 10%, NaCl 10%, and the rest is clay; after crushing the waste dechlorination agent, add 120ml of water, stir and filter, and dry the solid residue for later use; the filtered solution is passed through a polystyrene system Strongly basic anion exchange resin bed, after hydroxide ion exchange and adsorption of chloride ions, after evaporation of part of the water in the lye, the water content in the lye is 50%, and solid slag is mixed into the lye treated above, 20g Hydroxymethyl cellulose is kneaded evenly on a kneader, and the kneaded material is extruded on an extruder to form a regenerated fresh dechlorination agent after drying and roasting. The roasting temperature is 600 ° C and the roasting time is 10 hours.

[002...

Embodiment 3

[0030] Take by weighing 150g waste dechlorination agent, this waste dechlorination agent is to be applied to the waste dechlorination agent that removes hydrogen chloride in the regeneration gas of catalytic reforming unit, and its component is Na 2 CO 3 20%, Ca(OH) 2 25%, NaCl 10%, CaCl 2 10%, the rest is clay; after the waste dechlorination agent is pulverized, add 200ml of water, after stirring and settling for filtration, dry the solid residue for use; After hydroxide ion exchange and adsorption of chloride ions, after lye lye evaporated part of the water, the moisture content in lye lye was 48% at this moment, add solid residue, 20g hydroxymethyl cellulose, knead evenly on the kneader, kneaded The material is extruded on an extruder, dried and roasted to obtain a regenerated fresh dechlorination agent. The roasting temperature is 600°C and the roasting time is 10 hours.

[0031] The present embodiment obtains the fresh dechlorination agent of regeneration, has the foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com