Preparation method for novel metallocene polypropylene catalyst

A metallocene polypropylene and catalyst technology, applied in the production of bulk chemicals, etc., can solve problems such as increasing the production cost of polypropylene products and restricting industrial applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

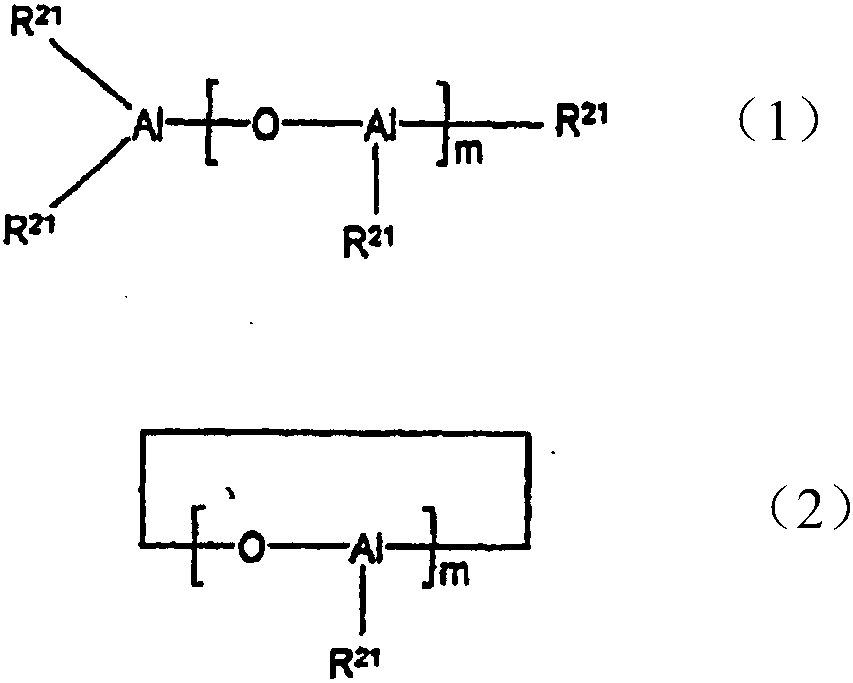

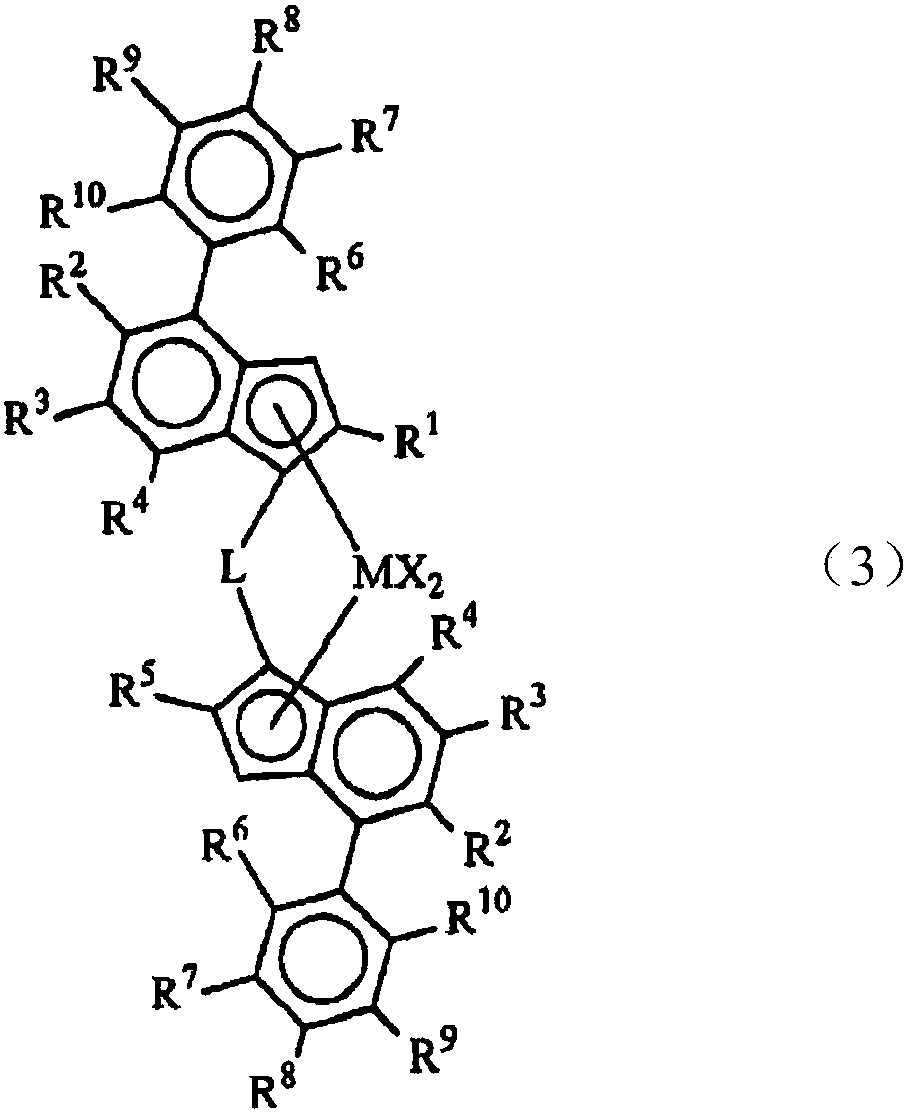

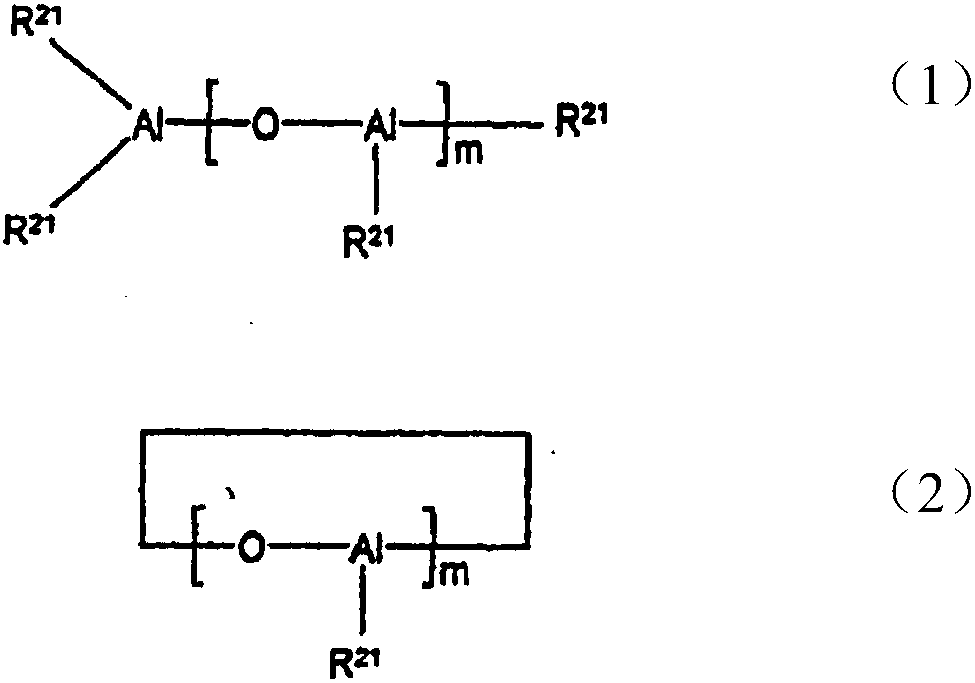

Embodiment 1

[0055] Accurately weigh 1 g of silica gel pretreated at 600°C, suspend it in 20 ml of toluene, and add 1 mmol of BF 3 The solution was stirred at room temperature for 2 h, and then the solid part was washed three times with 20 ml of toluene. get BF 3 Modified SiO 2 . Add 27 mmol MAO solution, stir at 50 °C for 2 h, and then wash the solid part with 20 ml of toluene 3 times to obtain MAO-modified SiO 2 . Add 20ml of toluene, then add dimethylsilanediylbis(2-methyl-4-phenylindenyl)zirconium dichloride and dimethylsilanediylbisindenylzirconium dichloride in an equimolar ratio. Stir at room temperature for 2h, the solid part is washed 3 times with 20ml of toluene, and the solvent is removed at room temperature to obtain a supported catalyst CAT4 (zirconium load: 5mgZr / gSiO 2 ).

Embodiment 2

[0057] Accurately weigh 1 g of pretreated silica gel at 600°C, suspend it in 20 ml of toluene, and add 2 mmol of BF 3 The solution was stirred at room temperature for 2h, and then the solid part was washed three times with 20ml of toluene to obtain BF 3 Modified SiO 2. Add 27 mmol MAO solution, stir at 50 °C for 2 h, and then wash the solid part with 20 ml of toluene 3 times to obtain MAO-modified SiO 2 . Add 20ml of toluene, then add dimethylsilanediylbis(2-methyl-4-phenylindenyl)zirconium dichloride and dimethylsilanediylbisindenylzirconium dichloride in an equimolar ratio. Stir at room temperature for 2 h, wash the solid part with 20 ml of toluene 3 times, and remove the solvent at room temperature to obtain a supported catalyst CAT5 (zirconium loading: 5 mgZr / gSiO) 2 ).

[0058] Aggregation process

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com