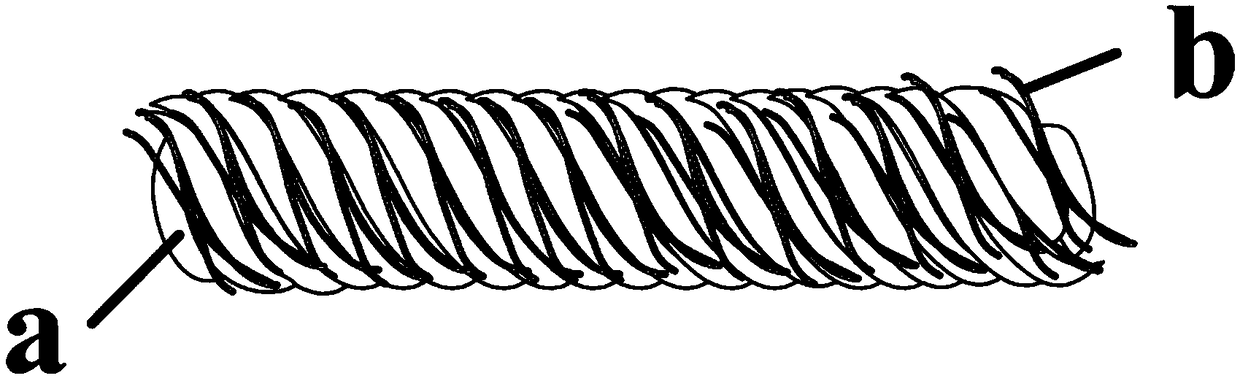

Preparation method of composite yarn containing metal organic skeleton nanometer fibers

A metal-organic framework and nanofiber technology, applied in the field of fiber materials, can solve problems such as poor performance controllability, difficulty in large-scale production, and complex processes, and achieve a large number of active sites, mass production of process operations, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

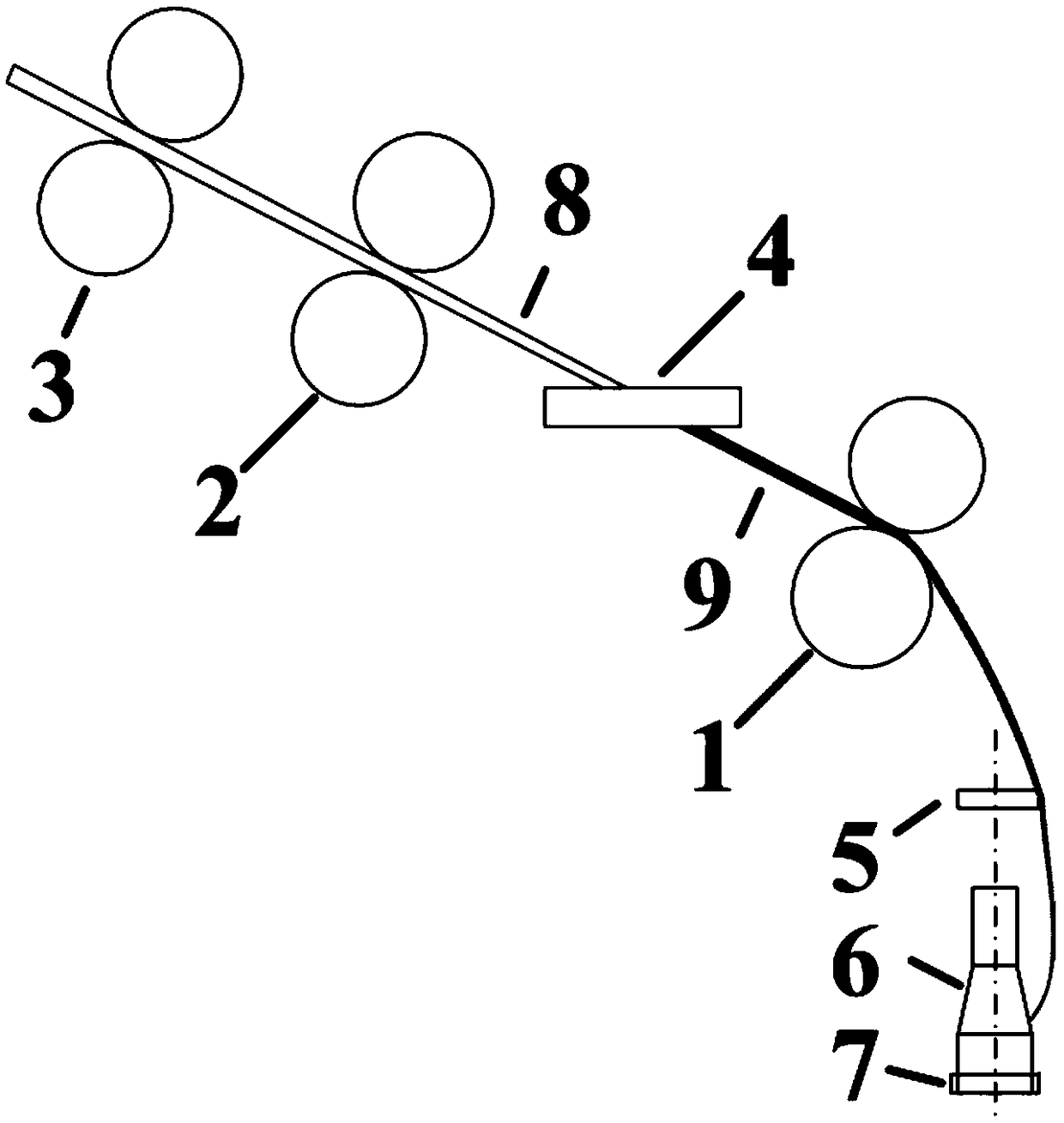

Method used

Image

Examples

Embodiment 1

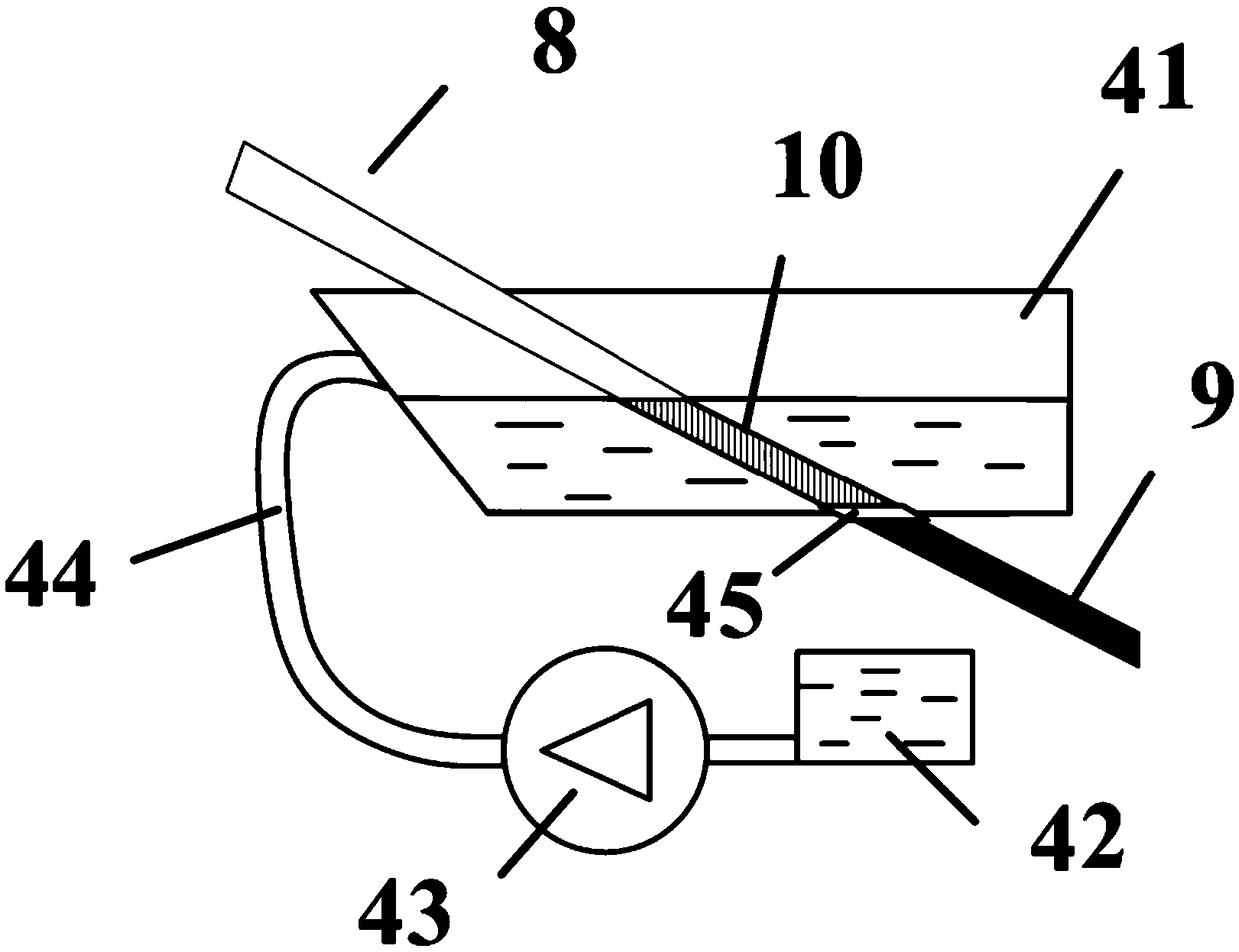

[0040] Configure 0.01mol / L europium nitrate hexahydrate (Eu(NO 3 ) 3 ·6H 2 (2) solution, wherein solvent is the mixed solvent of ethanol and water that volume ratio is 1:1, configures the trimesic acid (BTC) solution of 0.01mol / L, and wherein solvent is the ethanol and water that volume ratio is 1:1 Mixing solvents, mixing the europium nitrate hexahydrate solution and the trimesic acid solution at a volume ratio of 1:1, and uniformly shaking the mixed solution in a water-bath shaker at 20°C for 12 hours to prepare metal-organic framework nanofibers, the The fibers were washed with deionized water, filtered with suction, and dried to obtain a white solid powder. Then place the white solid powder in a mixed solvent of ethanol and water with a volume ratio of 3:2, and stir thoroughly to obtain a metal-organic framework nanofiber suspension. The metal-organic framework nanofiber suspension was placed in image 3 In the immersion tank 41 of the shown line finishing device 4, comb...

Embodiment 2

[0044] Configure 0.01mol / L gadolinium nitrate hexahydrate (Ga(NO 3 ) 3 ·6H 2 (0) solution, wherein the solvent is a mixed solvent of methanol and water with a volume ratio of 1:1, configure 0.01mol / L of 1,3,5-three (4-carboxyphenyl) (BTBC) benzene solution, wherein the solvent is A mixed solvent of methanol and water with a volume ratio of 2:1, the gadolinium nitrate pentahydrate solution and 1,3,5-tri(4-carboxyphenyl)benzene solution are mixed according to a volume ratio of 2:1, mixed Ga(BTBC)MOFs nanofibers were prepared by shaking the solution uniformly in a water-bath shaker at 20°C for 12 hours, and the fibers were washed with deionized water, filtered with suction, and dried to obtain a white solid powder. Then the white solid powder was placed in a mixed solvent of methanol and water with a volume ratio of 3:2, and stirred thoroughly to obtain a suspension of Ga(BTBC)MOFs nanofibers.

[0045] In the wet spinning process, the hemp fiber roving was filled with the Ga(B...

Embodiment 3

[0047] Configure 0.01mol / L copper nitrate pentahydrate (CuSO 4 ·5H 2 (2) solution, wherein the solvent is a mixed solvent of methanol and water with a volume ratio of 1:1, the nitrilotriacetic acid (NTA) solution of configuration 0.01mol / L, wherein the solvent is a mixture of methanol and water with a volume ratio of 2:1 Mix the solvent, mix the copper nitrate solution and the nitrilotriacetic acid solution according to the volume ratio of 3:1, and shake the mixed solution uniformly in a water-bath shaker at 20°C for 12 hours to prepare metal-organic framework nanofibers, and use the fibers Wash with deionized water, suction filter, and dry to obtain a white solid powder. Then the white solid powder was placed in a mixed solvent of methanol and water with a volume ratio of 3:2, and stirred thoroughly to obtain a suspension of Cu(NTA)MOFs nanofibers.

[0048] In the wet spinning process, the polyamide fiber roving was filled with the Cu(NTA)MOFs nanofiber suspension in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com