Construction device and construction method for curing ultra-high performance concrete filled steel tubular column at room temperature

A concrete-filled steel tubular column, ultra-high performance technology, applied in the direction of columns, piers, pillars, etc., can solve problems such as difficult application and inability to implement on-site, and achieve the effects of good feasibility, convenient construction and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

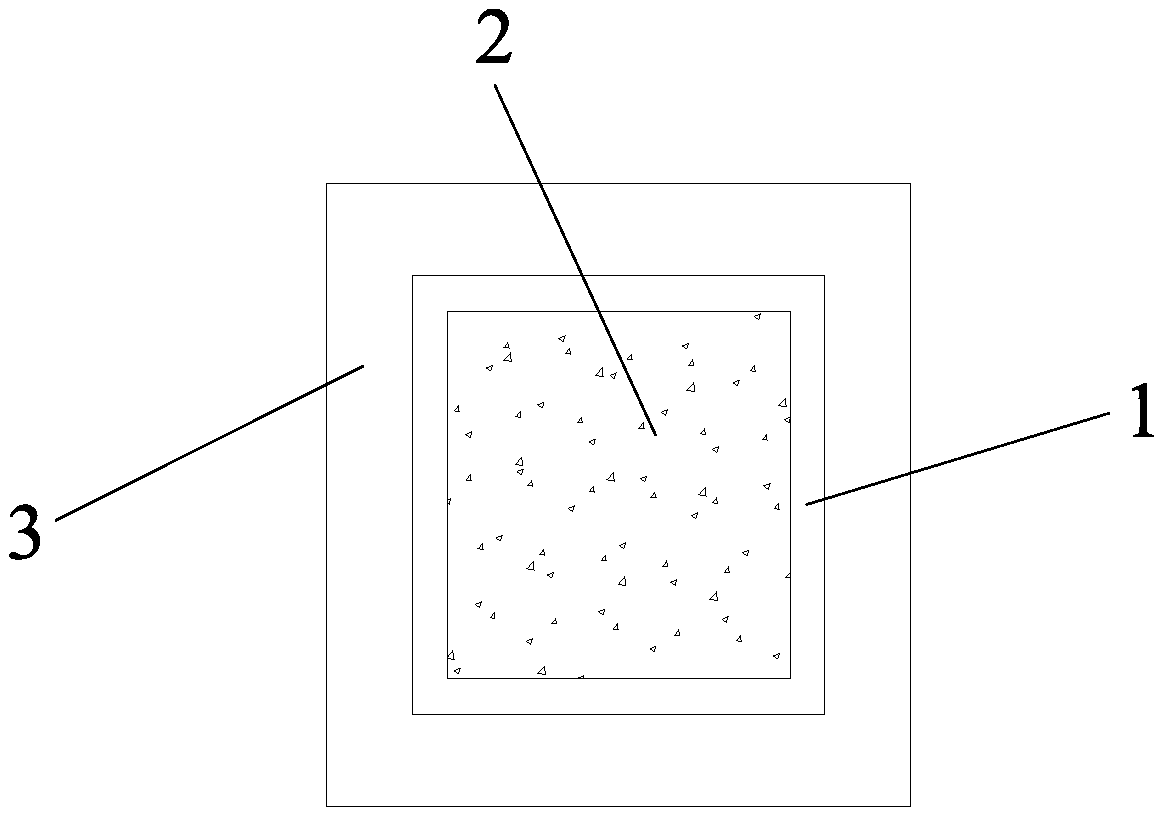

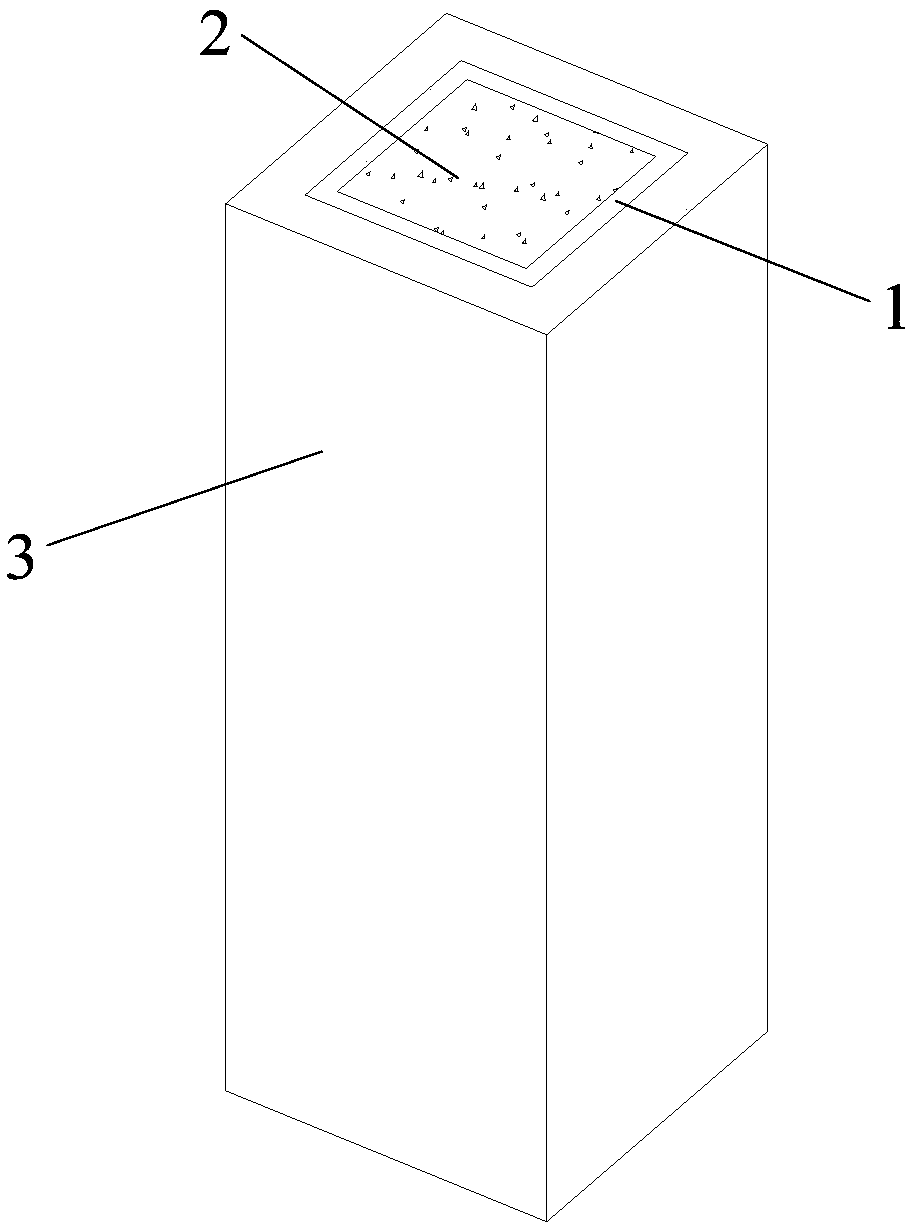

[0021] Please check Figure 1-2 , a construction device for maintaining ultra-high performance steel pipe 1 concrete column 2 at room temperature in this embodiment, including concrete column 2, steel pipe 1, and insulation layer 3;

[0022] The thermal insulation layer 3 is a layer of high foamed polyethylene material, which is sealed on the outer periphery of the steel pipe 1;

[0023] The interior of the steel pipe 1 is filled with concrete columns 2, and the temperature inside the steel pipe 1 is 70-90°C;

[0024] The concrete column 2 is composed of water, cement, silica fume, quartz powder, polycarboxylate superplasticizer, quartz sand and sodium polyacrylate according to the mass ratio of 0.2:1:0.15:0.2:0.009:1.75:0.03 It is mixed; the sodium polyacrylate added in the component can absorb 15 to 30 times the water of its own weight during the concrete mixing process, and provide sufficient hydration water for the concrete in the early stage of curing. The polycarboxyla...

Embodiment 2

[0027] Adopt embodiment 1 device to carry out the method for maintenance construction, may further comprise the steps:

[0028] 1) Mix water, cement, silica fume, quartz powder, polycarboxylate superplasticizer, quartz sand and sodium polyacrylate in a mass ratio of 0.2:1:0.15:0.2:0.009:1.75:0.03, and put in In the concrete mixer, stir for 15 to 20 minutes to obtain finished concrete;

[0029] 2) Pour the finished concrete into the steel pipe 1, vibrate for 1-2 minutes every time one-third of the height of the steel pipe 1 is poured, until all the pouring is completed;

[0030] 3) Maintain the temperature of the steel pipe 1 and the finished concrete at 70-90°C, uniformly cover the steel pipe 1 with a layer of high foamed polyethylene as the insulation layer 3, and use glue to bond the high foamed polyethylene insulation layer 3 and the steel pipe 1 together , when the insulation layer 3 is bonded and sealed, it is bonded under slight extrusion, so that the bonding surfaces o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com