High-speed switching diode chip and production technology

A high-speed switching and diode technology, applied in electrical components, electrical solid devices, circuits, etc., to reduce reverse leakage current, shorten switching time, and reduce layout size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

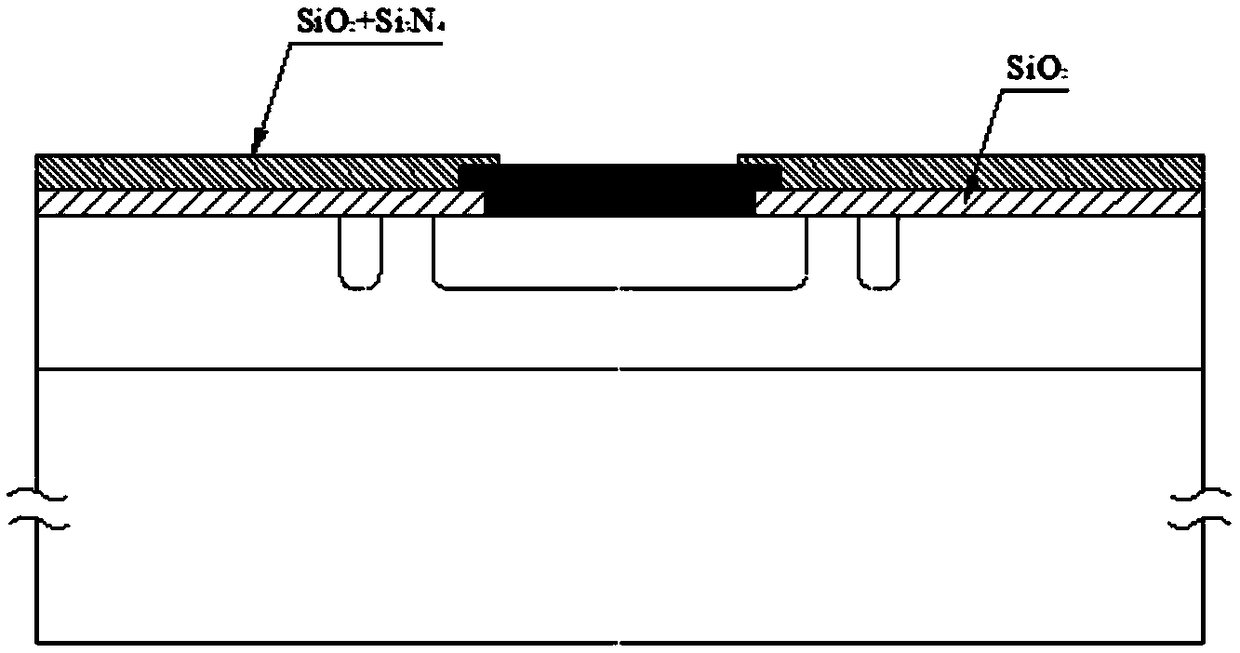

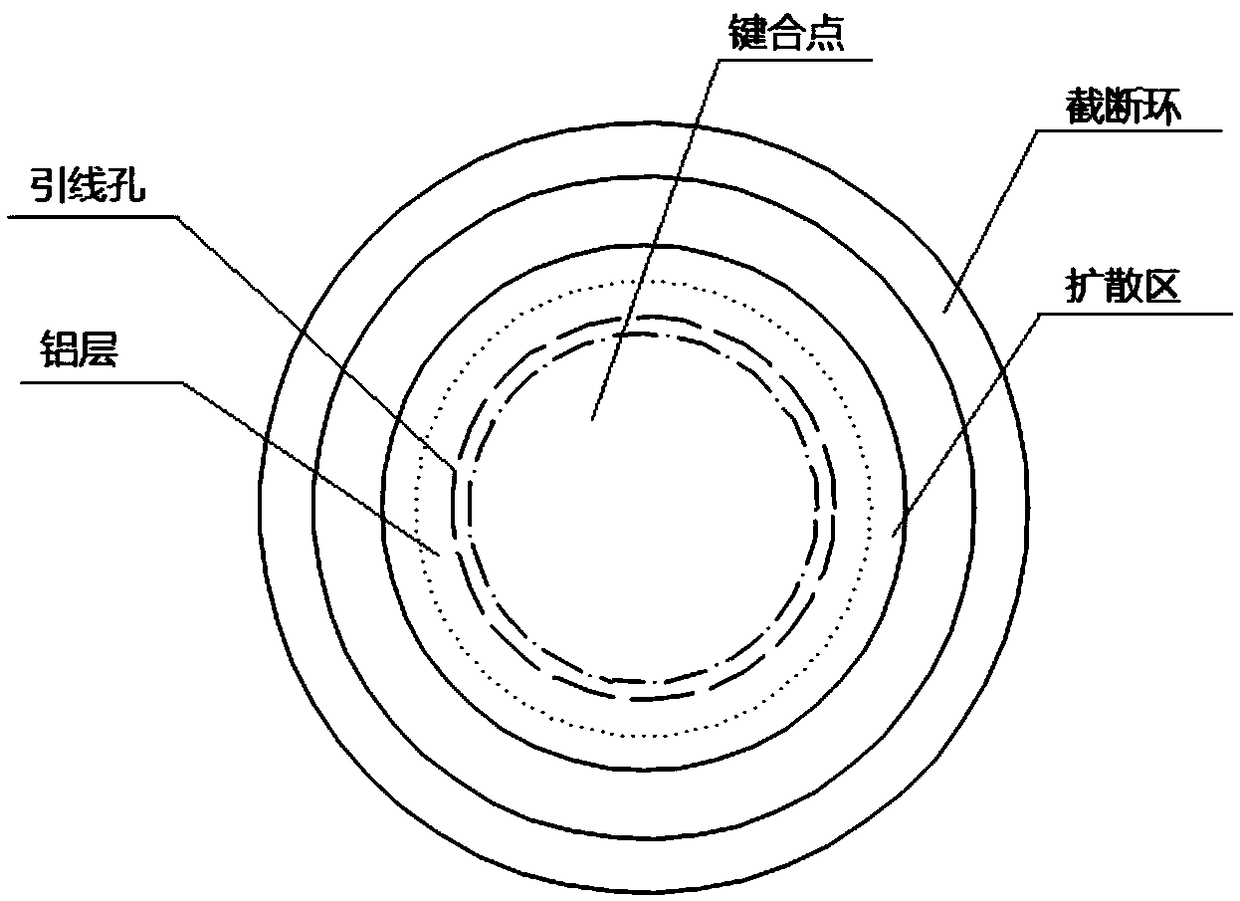

[0045] As introduced in the background technology, in the prior art, the capacitance of the diode barrier capacitance itself seriously affects the switching performance of the diode, resulting in long switching time and other shortcomings. In order to solve the above technical problems, this embodiment proposes a high-speed switching diode chip, such as figure 1 As shown, the cross-section of the chip is circular, including:

[0046] a substrate, an epitaxial layer is grown on the upper surface of the substrate;

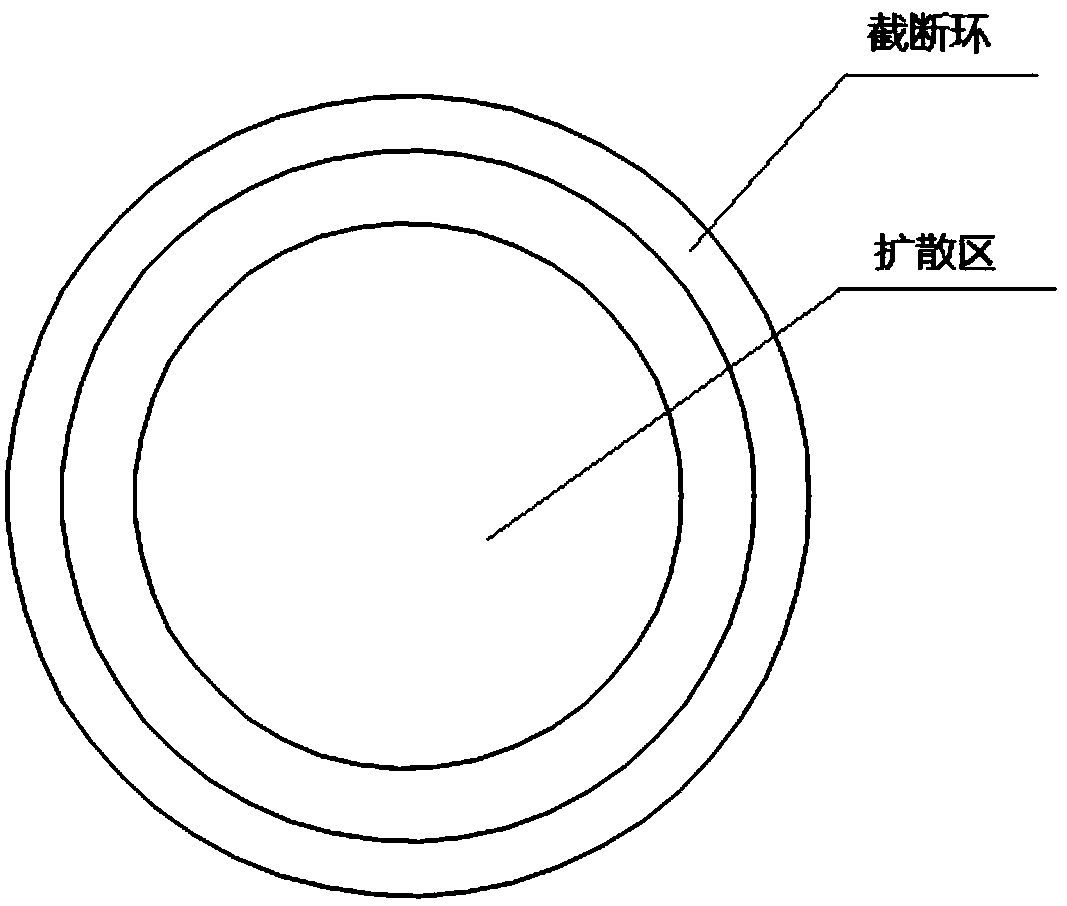

[0047] The upper surface of the epitaxial layer is a first oxide layer, and an annular isolation groove is photolithographically etched on the first oxide layer, the inside of the isolation groove is a diffusion area, and the outside of the isolation groove is a truncation ring;

[0048] The upper surface of the first oxide layer is a second oxide layer, and lead holes are photolithographically etched on the second oxide layer;

[0049] An evaporated aluminum layer...

Embodiment 2

[0064] The purpose of this embodiment is to provide the production process of the high-speed switching diode, including primary oxidation, photolithography in the diffusion area, diffusion in the diffusion area, secondary oxidation, photolithography of lead holes, steaming gold, gold diffusion, grinding, steaming aluminum, Aluminum anti-etching, alloying, and passivation, specifically, include the following steps:

[0065] (1) Once oxidized, a silicon dioxide film is generated on the surface of the epitaxial layer;

[0066] The process parameters are: temperature 1000℃~1200℃, oxygen flow 3.3~5.3L / min, hydrogen 3.3~5.3L / min, time 65~75min;

[0067] (2) Photolithography in the diffusion area, the area of the diffusion area is not greater than 1.33×10 5 μm 2 ;

[0068] The process parameters are: the speed of uniform glue is not less than 4000 rpm; the exposure time is not less than 35s.

[0069] (3) Diffusion in the diffusion area to obtain a diffusion area and a truncated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com