High loading capacity metal single atom proton exchange membrane fuel cell catalytic materials, and preparation method thereof

A proton exchange membrane and fuel cell technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the problems of limited sites, limit the application of single-atom catalysts, and low loading, and achieve improved The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

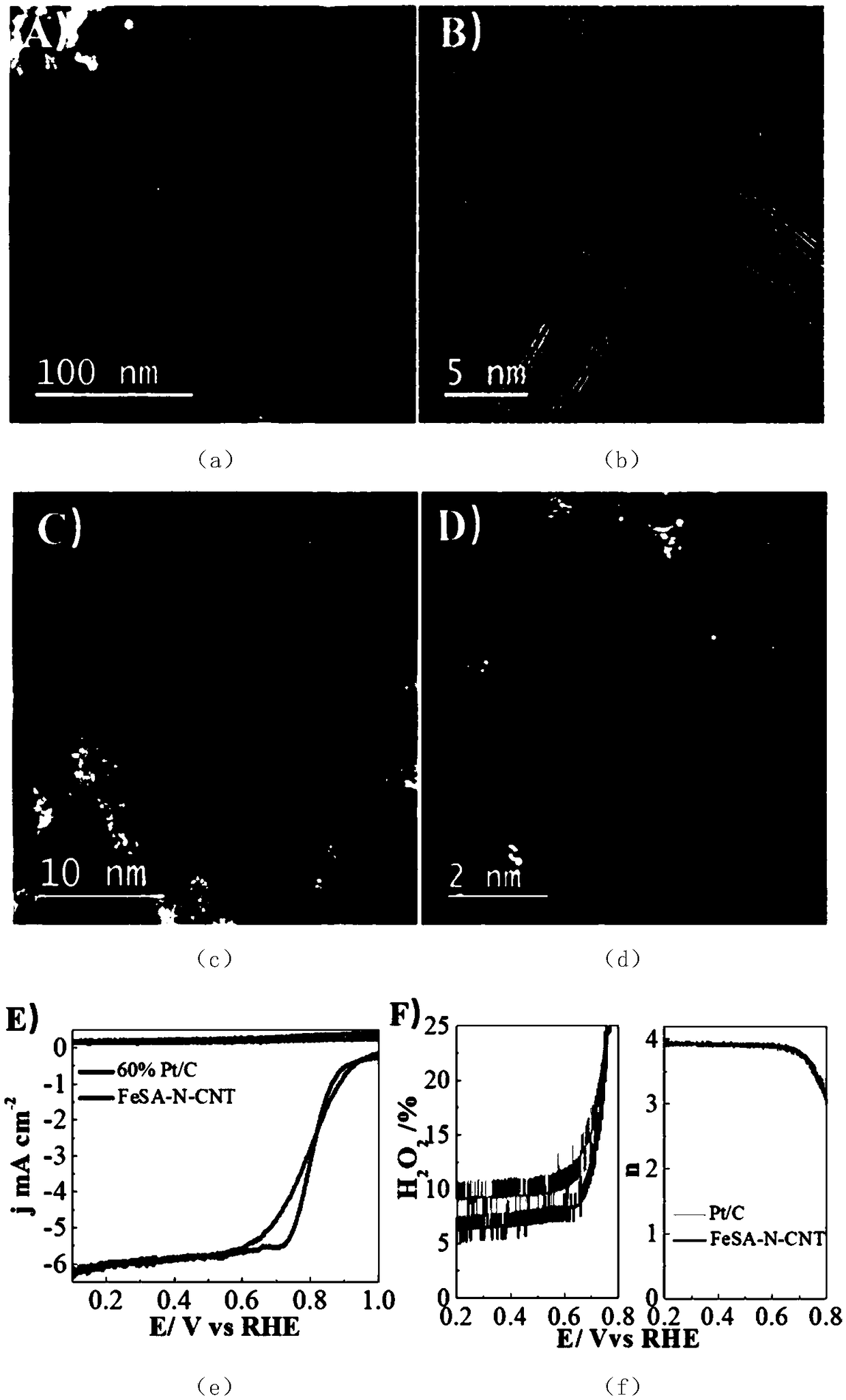

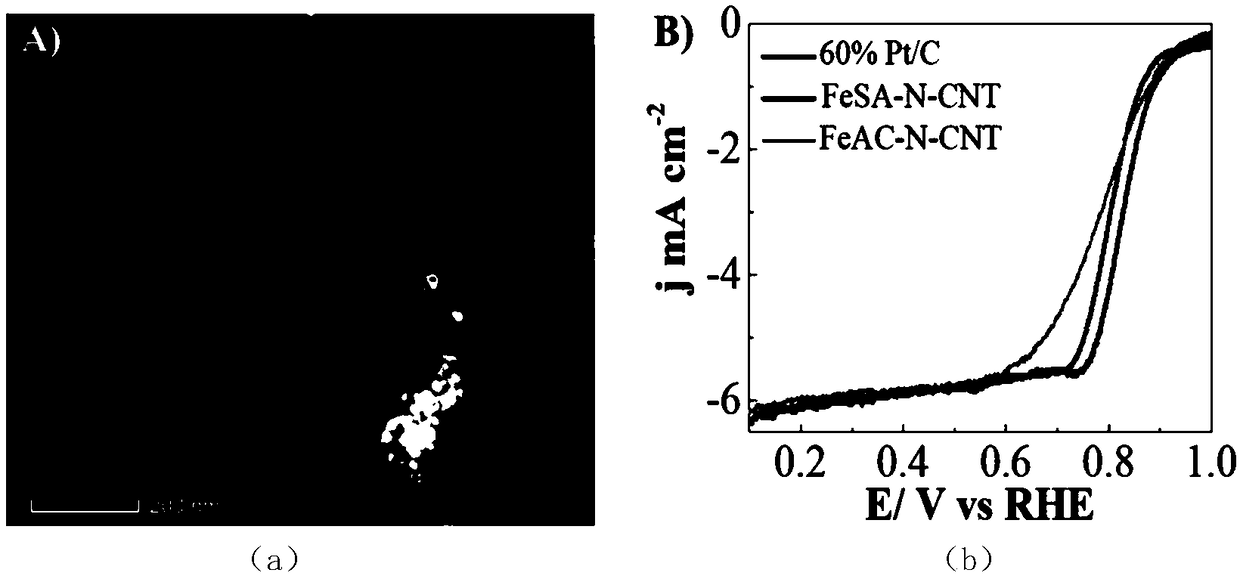

[0028] Take 10 grams of dicyanamide, 100 mg of carbon dioxide tube and 100 mg of hemoglobin, add 10 ml of ethanol and grind until mixed evenly. For protective gas (flow rate is 80sccm), the temperature rises to 300°C at a rate of 1°C / min, the heat treatment time is 3 hours under argon, and the temperature continues to rise to 600°C, and after 3 hours of treatment under argon, continue to heat up to 900°C , treated for 1 hour, and cooled to room temperature. A black sample 1 (FeSA-N-CNT) was taken out. As a comparison, take 10 grams of dicyanamide, 100 mg of carbon oxide tubes and 100 mg of iron acetylacetonate, and synthesize sample 1 (FeSA-N-CNT) and black sample 2 (FeAC-N-CNT) according to the above synthesis method. figure 1 Medium transmission electron microscope pictures (a-b) show that the surface of the prepared sample 1 carbon nanotubes is covered with a layer of amorphous carbon thin layer and there is a graphene-like structure between the carbon tubes, further high-...

Embodiment 2

[0030] Take 10 grams of dicyanamide, 100 mg of carbon dioxide tubes, 100 mg of heme and 10 mg of copper phthalocyanine, add 10 ml of ethanol and grind until mixed evenly, repeat 5 times, dry at room temperature, grind evenly to obtain a light powder, place in In the furnace, use argon as protective gas (flow velocity is 80 sccm), rise to 300°C at a rate of 1°C / min, heat treatment time under argon is 3 hours, continue to heat up to 600°C, and process under argon for 3 hours, Continue to raise the temperature to 900° C., treat for 1 hour, cool down to room temperature, and take out the black sample 3 (FeCuSA-N-CNT). As a comparison, take 10 grams of dicyanamide, 100 mg of carbon dioxide tubes, 100 mg of heme and 10 mg of copper phthalocyanine, add 10 ml of ethanol and grind until the mixture is uniform, repeat 5 times, dry at room temperature, and grind evenly to obtain a shallow powder , placed in a furnace with argon as a protective gas (flow rate of 80sccm), rising to 900°C a...

Embodiment 3

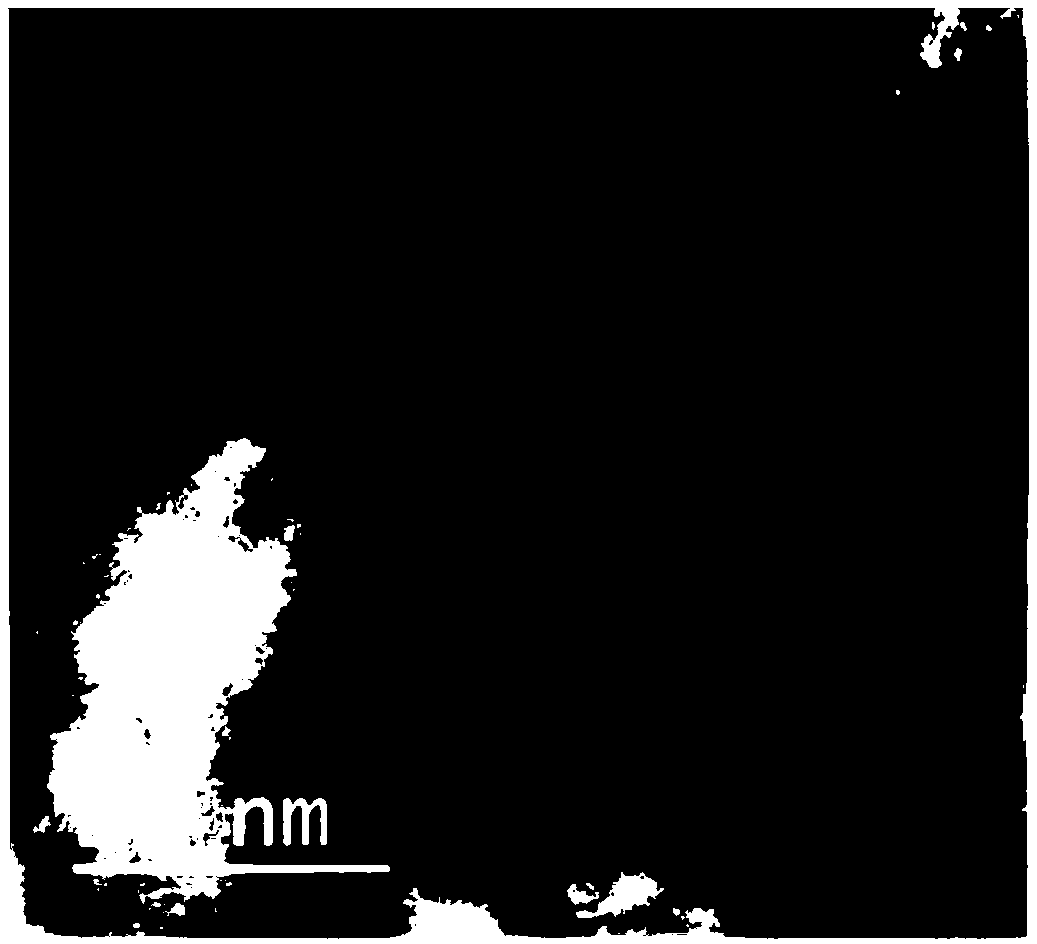

[0032] Take 10 grams of dicyanamide, 100 mg of graphene oxide, 100 mg of heme and 10 mg of copper phthalocyanine, add 10 ml of ethanol and grind until mixed evenly, repeat 5 times, dry at room temperature, grind evenly to obtain a light powder, place in In the furnace, use argon as protective gas (flow velocity is 80 sccm), rise to 300°C at a rate of 1°C / min, heat treatment time under argon is 3 hours, continue to heat up to 600°C, and process under argon for 3 hours, Continue to heat up to 900 degrees, process for 1 hour, and cool down to room temperature. A black sample 5 (FeCuSA-N-G) was taken out. Figure 4 SEM and TEM images (a-b) in the middle show that sample 5 has a graphene single-layer structure. In the further high-resolution high-angle annular dark field image (c), it can be clearly seen that single iron-copper atoms are distributed on the graphene structure. According to thermogravimetric analysis, the total content of iron and copper is about 7-8wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com