Pollution-control synergistic method for in-situ remediation of organically polluted farmland soil

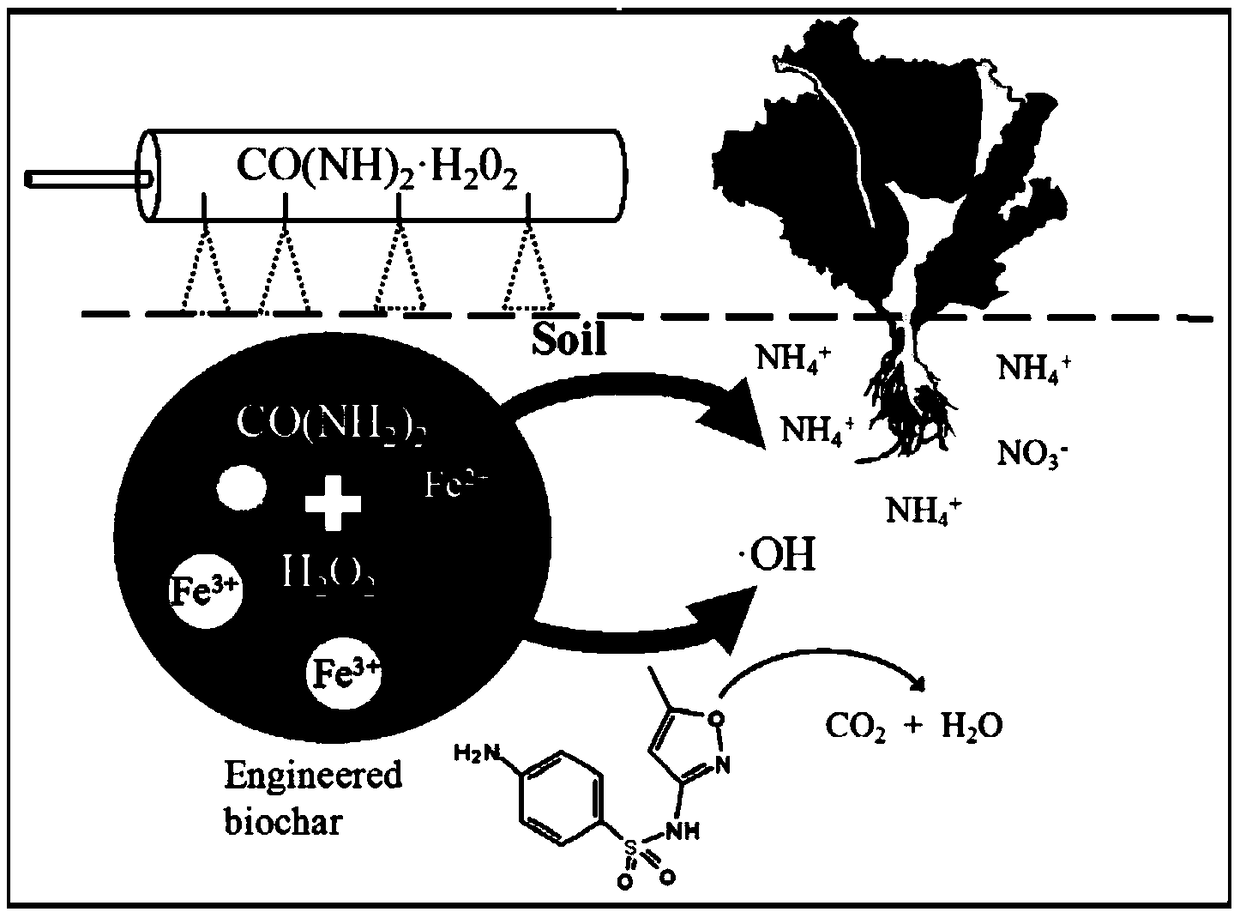

An organic pollution and in-situ remediation technology, applied in the field of soil remediation, can solve the problems of urea peroxide failure, insufficient pollutant degradation ability, and no consideration of the improvement of farmland soil fertility, etc., to achieve enhanced degradation ability, improved degradation, and improved degradation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

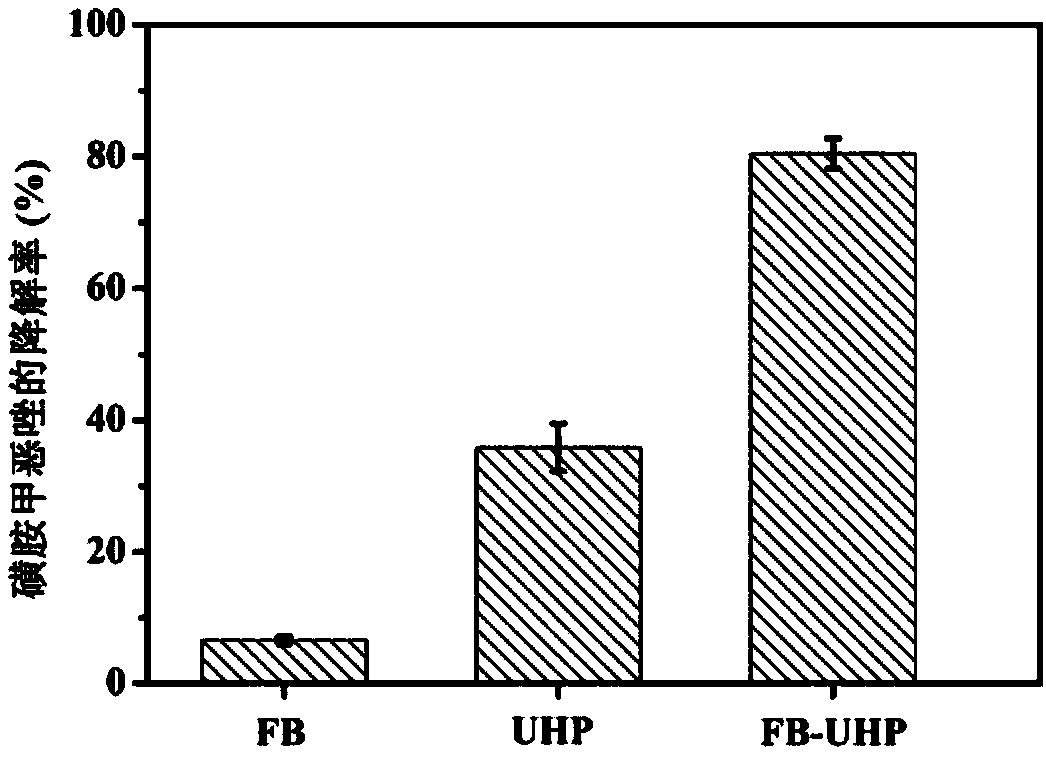

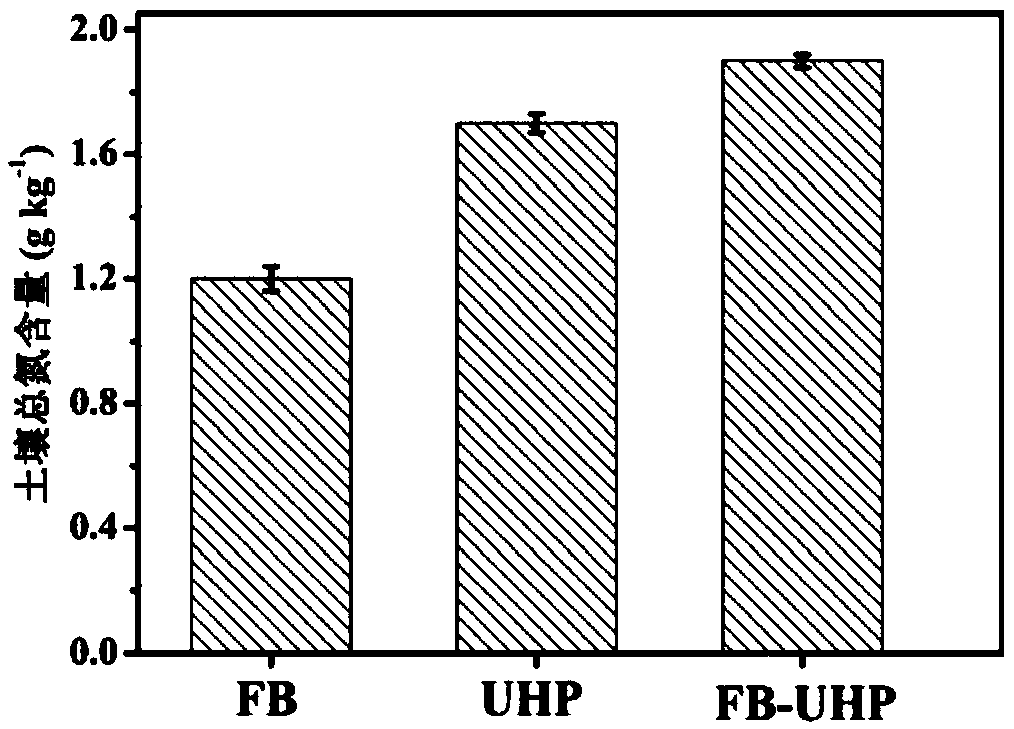

[0051] This example relates to a pollution control and efficiency-enhancing method for in-situ remediation of farmland organically polluted soil, and specifically relates to the effect of modified biochar activated urea peroxide on soil sulfamethoxazole degradation and nitrogen content, and the method includes the following steps :

[0052] (1) Preparation of modified biochar:

[0053] Soak 20g of corn stalks sieved through a 100-mesh sieve in 100ml of 1mol / L FeSO 4 solution, dried after 2h. Place in a crucible for compaction, cover, place in a muffle furnace, heat up to 600°C for pyrolysis for 1 hour, cool to room temperature, deionize and wash 3 times, and dry to obtain the modified biochar material FB of this example.

[0054] (2) Mix the modified biochar with the soil:

[0055] In the artificially added concentration of 10mg / kg sulfamethoxazole-contaminated soil, the modified biochar was added at a ratio of 0.5% to the soil, and the pH of the soil was 6 after adding the...

Embodiment 2

[0061] Example 2 Degradation efficiency of sulfamethoxazole by different pyrolysis temperature modified biochar activated urea peroxide

[0062] This embodiment relates to the degradation efficiency of sulfamethoxazole by the modified biochar activated urea peroxide at different pyrolysis temperatures, including the following steps:

[0063] (1) Preparation of modified biochar:

[0064] Soak 20g of corn stalks shavings through a 100 mesh sieve in 100ml of 1mol / L Fe 2+ Aqueous solution, dry after 2h. Place in a crucible for compaction, cover, place in a muffle furnace, heat up to different temperatures (specifically 200°C, 300°C, 400°C, 500°C, 600°C), pyrolyze for 1 hour, cool to room temperature, and deionize Washing 3 times and drying to obtain various modified biochar materials of this embodiment.

[0065] (2) Mix the modified biochar with the soil:

[0066] In the artificially added concentration of 10mg / kg sulfamethoxazole-contaminated soil, the modified biochar was ...

Embodiment 3

[0070] Example 3 Degradation efficiency of modified biochar activated urea peroxide to sulfamethoxazole under different pH

[0071] The present embodiment relates to the degradation efficiency of modified biochar activated urea peroxide to sulfamethoxazole under different pH, comprising the following steps:

[0072] (1) Preparation of modified biochar:

[0073] Soak 20g of corn stalks shavings through a 100 mesh sieve in 100ml of 1mol / L Fe 2+ Aqueous solution, dry after 2h. Place in a crucible for compaction, cover, place in a muffle furnace, heat up to 600°C for 1 hour, cool to room temperature, wash with deionization three times, and dry to obtain the modified biochar material of this example.

[0074] (2) Mix the modified biochar with the soil:

[0075] In the artificially added concentration of 10mg / kg sulfamethoxazole-contaminated soil, add modified biochar with a soil doping ratio of 0.5%, and adjust the pH of the soil to pH with HCl or NaOH with a concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com