Preparation method for dendritic nano silicon particle

A nano-silicon and dendritic technology, applied in the field of preparation of dendritic nano-silicon particles, can solve the problems of affecting product safety, difficulty in scaling up production and manufacturing, etc., and achieve the effects of easy expansion of production, low production cost and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

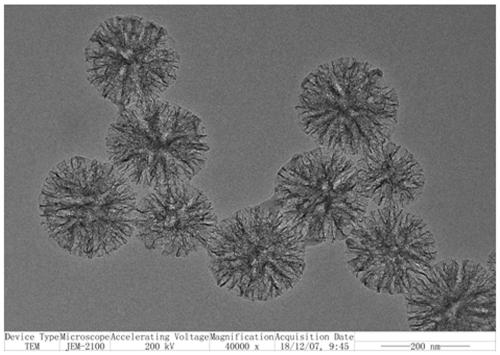

[0033] Add 1.5 g of cetyltrimethylammonium bromide and 0.7 g of sodium octanoate (1:1 molar ratio) into 100 ml of deionized water, stir and dissolve at 95°C for 30 minutes, add 10 ml of ethyl orthosilicate Stir the reaction for 2 hours, centrifuge at 6000 rpm for 10 minutes, discard the supernatant; disperse and centrifuge with 30 ml of water or ethanol, repeat washing 2-3 times, and dry to obtain dendritic nano-silicon with a particle size of 219±24 nm particles ( figure 1 ).

Embodiment 2

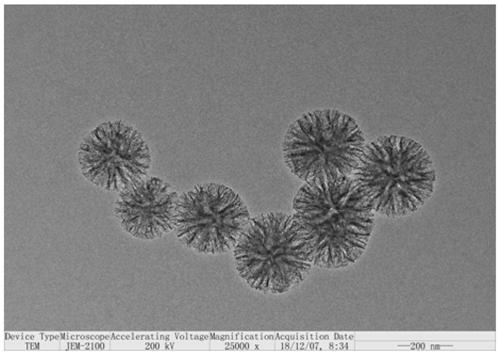

[0035] Add 1.5 g of cetyltrimethylammonium bromide and 0.7 g of sodium octanoate (1:1 molar ratio) into 100 ml of deionized water, stir and dissolve at 95°C for 30 minutes, add 14 ml of ethyl orthosilicate Stir the reaction for 2 hours, centrifuge at 6000 rpm for 10 minutes, discard the supernatant; disperse and centrifuge with 30 ml of water or ethanol, repeat washing 2-3 times, and dry to obtain dendritic nano-silicon with a particle size of 275±20 nm particles ( figure 2 ).

Embodiment 3

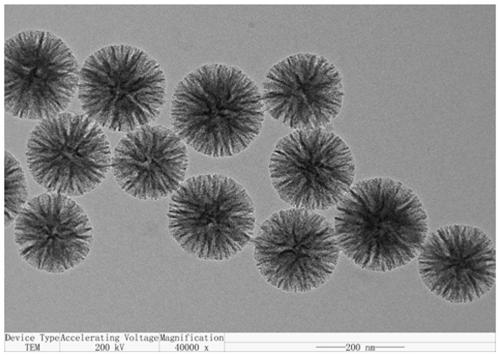

[0037] Add 1.5 g of cetyltrimethylammonium bromide and 0.35 g of sodium octanoate (molar ratio 1:0.5) into 100 ml of deionized water, stir and dissolve at 95°C for 30 minutes, add 14 ml of ethyl orthosilicate and stir After 8 hours of reaction, centrifuge at 6000 rpm for 10 minutes, discard the supernatant; disperse and centrifuge with 30 ml of water or ethanol, and wash repeatedly 2-3 times to obtain dendritic nano-silicon particles with a particle size of 220±9 nm ( image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com