Preparation method of precursor sol for metatitanic acid lithium ion sieve

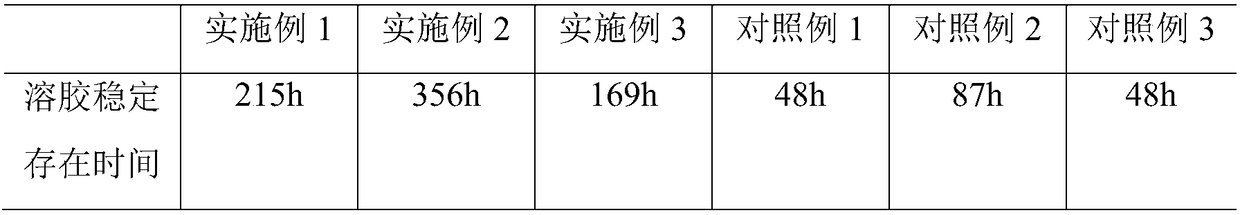

A lithium ion and precursor technology is applied in the field of preparation of precursor sol for metatitanate lithium ion sieve, which can solve the problems of inability to meet production requirements, increase in sol viscosity, and difficulty in repeated loading of sol, so as to improve load utilization. The effect of increasing the rate, uniform dispersion, and prolonging the stable existence time of the sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the precursor sol for metatitanate type lithium ion sieve of the present embodiment, it comprises:

[0031] (1) Add methanol, Gemini surfactant and triethanolamine to deionized water and stir evenly to obtain a mixed surfactant solution; wherein methanol, Gemini surfactant and triethanolamine account for 0.05% of the total volume of the mixed surfactant solution respectively %, 0.01% and 0.5%, and the Gemini surfactant is a cationic Gemini surfactant.

[0032] (2) Put titanium sulfate in deionized water and stir until it is completely dissolved, then after purification by weakly basic anion exchange resin, adjust the pH of the mixed solution purified by weakly basic anion exchange resin to 3, and then add it to the mixing surface The active agent solution is stirred until uniform to obtain a mixed solution;

[0033] (3) Add concentrated ammonia water to the mixed solution under stirring to adjust the pH to 8.5, and obtain a white precipitate; ...

Embodiment 2

[0038] The preparation method of the precursor sol for metatitanate type lithium ion sieve of the present embodiment, it comprises:

[0039] (1) Add methanol, Gemini surfactant and triethanolamine to deionized water and stir evenly to obtain a mixed surfactant solution; wherein methanol, Gemini surfactant and triethanolamine account for 0.07% of the total volume of the mixed surfactant solution respectively %, 0.05% and 0.75%, and the Gemini surfactant is a cationic Gemini surfactant.

[0040] (2) Put titanium sulfate in deionized water and stir until it is completely dissolved, then after purification by weakly basic anion exchange resin, after the pH of the mixed solution purified by weakly basic anion exchange resin is adjusted to 3.5, add mixed surface active agent solution, stirred until uniform, to obtain a mixed solution;

[0041] (3) adding concentrated ammonia water to the mixed solution under stirring to adjust the pH to 9 to obtain a white precipitate;

[0042] (4...

Embodiment 3

[0046] The preparation method of the precursor sol for metatitanate type lithium ion sieve of the present embodiment, it comprises:

[0047] (1) Add methanol, Gemini surfactant and triethanolamine to deionized water and stir evenly to obtain a mixed surfactant solution; wherein methanol, Gemini surfactant and triethanolamine account for 0.1% of the total volume of the mixed surfactant solution respectively %, 0.1% and 1%, and the Gemini surfactant is a cationic Gemini surfactant.

[0048] (2) Put titanium sulfate in deionized water and stir until completely dissolved, then after purification by weakly basic anion exchange resin, after the pH of the mixed solution purified by weakly basic anion exchange resin is adjusted to 4, add mixed surface active agent solution, stirred until uniform, to obtain a mixed solution;

[0049] (3) Add concentrated ammonia water to the mixed solution under stirring to adjust the pH to 8.5, and obtain a white precipitate;

[0050] (4) After clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com