Environment-friendly rock wool and production method thereof

A production method and technology for rock wool, applied in the field of rock wool processing, can solve the problems of increasing the production cost of rock wool, using large basalt solid waste, and difficulty in the mining process, and achieving the effects of reducing production costs, good quality, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

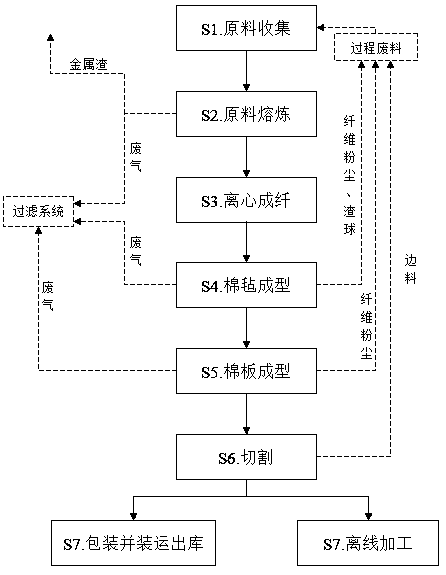

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides an environment-friendly rock wool. The weight percentage of each component of the environment-friendly rock wool is: 55% basalt, 15% blast furnace slag, 18% process waste, and 12% coke.

Embodiment 2

[0036] This embodiment provides an environment-friendly rock wool. The weight percentage of each component of the environment-friendly rock wool is: 50% basalt, 20% blast furnace slag, 20% process waste, and 10% coke.

Embodiment 3

[0038] This embodiment provides an environment-friendly rock wool. The weight percentage of each component of the environment-friendly rock wool is: 60% basalt, 15% blast furnace slag, 15% process waste, and 10% coke.

[0039] The environment-friendly rock wool of Examples 1, 2 and 3 are all prepared by the production method of the above-mentioned environment-friendly rock wool. After testing, the environmentally friendly rock wool in Examples 1, 2 and 3 all have good quality, and have good surfaces in terms of fire prevention, heat preservation, and ventilation.

[0040] The environmental protection rock wool and the production method of the environmental protection rock wool of the present invention use the process waste produced in the rock wool production process as one of the raw materials, which not only ensures the product quality, but also reduces the production cost, and at the same time saves the treatment of the process waste In addition, the metal slag is collected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com