A kind of preparation method of hydroxypivalic acid neopentyl glycol monoester and neopentyl glycol joint production

A technology of hydroxypivalic acid neopentyl glycol monoester and neopentyl glycol, which is applied in the field of co-production of hydroxypivalic acid neopentyl glycol monoester and neopentyl glycol, and can solve the problem that there is no hydroxy neopentyl glycol Acid Neopentyl Glycol Monoester and Neopentyl Glycol etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

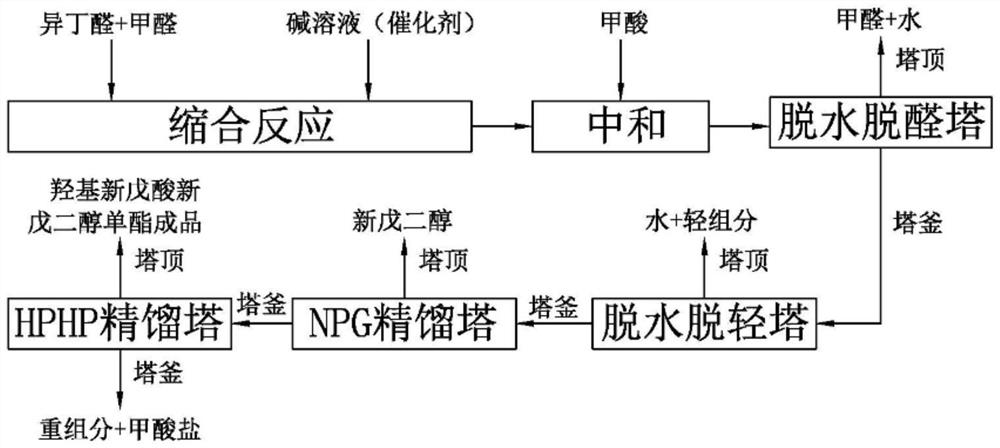

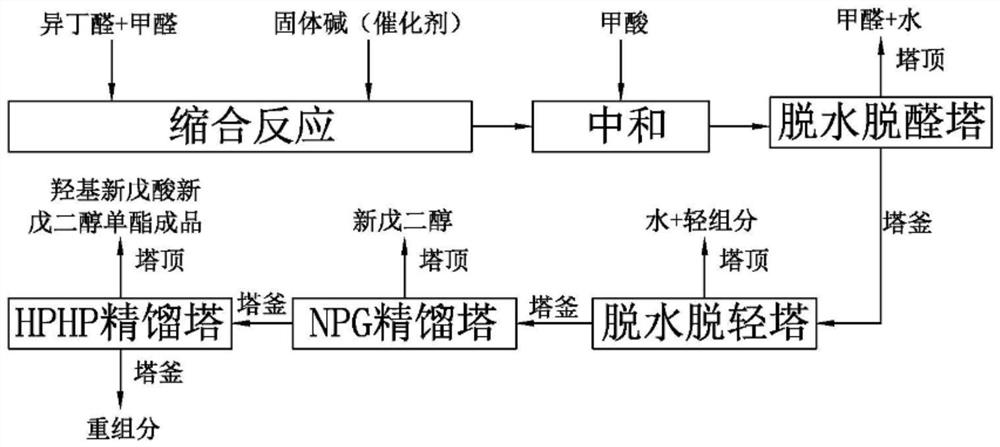

Method used

Image

Examples

Embodiment 1

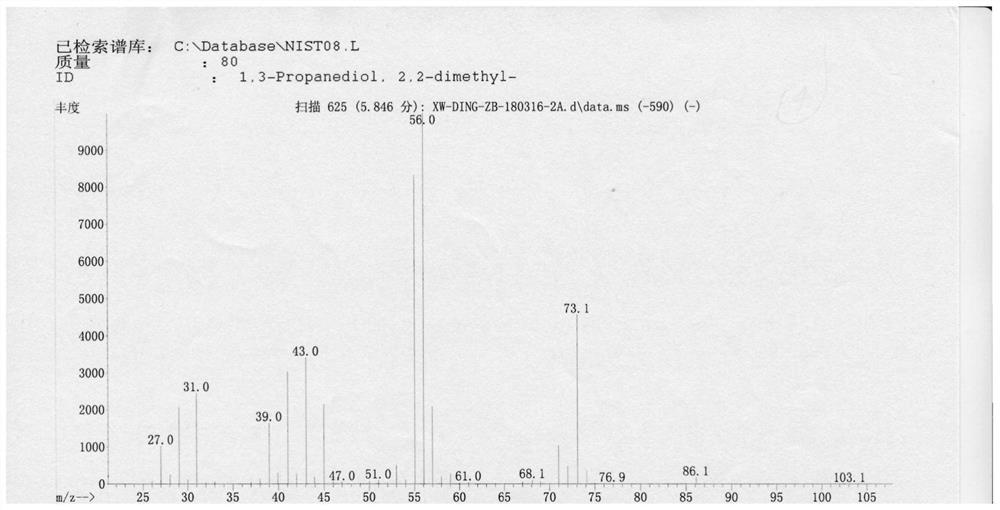

[0040] According to isobutyraldehyde: formaldehyde molar ratio = 1:1.75, put in isobutyraldehyde with a concentration of about 99% and formaldehyde with a concentration of about 37%, add deionized water 15 times the weight of isobutyraldehyde, keep the temperature of the material at 30°C, and add mass The concentration is 15% sodium hydroxide solution to control the pH value = 10.5; start the reactor to stir, and react at a constant temperature for 5 hours; stop adding the sodium hydroxide solution, raise the temperature to 60°C and keep the temperature constant for 1 hour, and neutralize with formic acid to pH = 6.8- 6.9; the condensation liquid passes through the dehydration and dehydration tower (positive pressure operation, gauge pressure 0.2MPa) to remove water and formaldehyde; Components: Dehydration and delightening tower still material obtains neopentyl glycol product (mass spectrogram such as image 3Shown); NPG rectifying tower tower bottom material obtains hydroxy ...

Embodiment 2

[0042] According to the molar ratio of isobutyraldehyde: formaldehyde = 1:1.85, put in isobutyraldehyde with a concentration of about 99% and formaldehyde with a concentration of about 37%, add deionized water 10 times the weight of isobutyraldehyde, keep the temperature of the material at 30°C, and add mass The concentration is 15% sodium hydroxide solution to control the pH value = 9.5; start the reactor to stir, and react at a constant temperature for 5 hours; stop adding the sodium hydroxide solution, raise the temperature to 60°C and keep the temperature for 1 hour, and neutralize with formic acid to pH = 6.8- 6.9; the condensation liquid passes through the dehydration and dehydration tower (positive pressure operation, gauge pressure 0.1MPa) to remove water and formaldehyde; Components; dehydration and lightening tower bottom material obtains neopentyl glycol product (mass spectrogram is consistent with embodiment 1, does not repeat to provide) through NPG rectification t...

Embodiment 3

[0044] Fill the fixed bed reactor according to the ratio of isobutyraldehyde:basic group in the solid base = 1:1.0, and the solid base adopts a quaternary ammonium group [N—(CH 3 ) 2 C 2 h 4 OH] anion exchange resin; according to isobutyraldehyde: formaldehyde molar ratio=1:1.85 drops into the isobutyraldehyde of concentration about 99% and the formaldehyde of concentration about 37%, add the deionized water of 10 times of isobutyraldehyde weight; Constant temperature to 35°C, turn on the circulation pump of the fixed bed reactor for 6 hours; take 1 hour to raise the temperature to 50°C at a constant speed and keep the temperature at 50°C for 1 hour; filter the condensation liquid so that it does not contain solid alkali catalyst; the condensation liquid is dehydrated and dealdehyded The column (positive pressure operation, gauge pressure 0.3MPa) removes water and formaldehyde; the material in the dehydration and light removal tower (negative pressure operation, absolute pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com