Good-surface high-impact PA (Polyamide)/POK (Polyketone) alloy and preparation method thereof

A high-impact, alloy technology, applied in the field of good surface high-impact anti-warpage nylon/POK alloy and its preparation, can solve the problems of serious floating fibers on the surface, achieve good appearance performance, avoid product warpage, and improve warpage defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

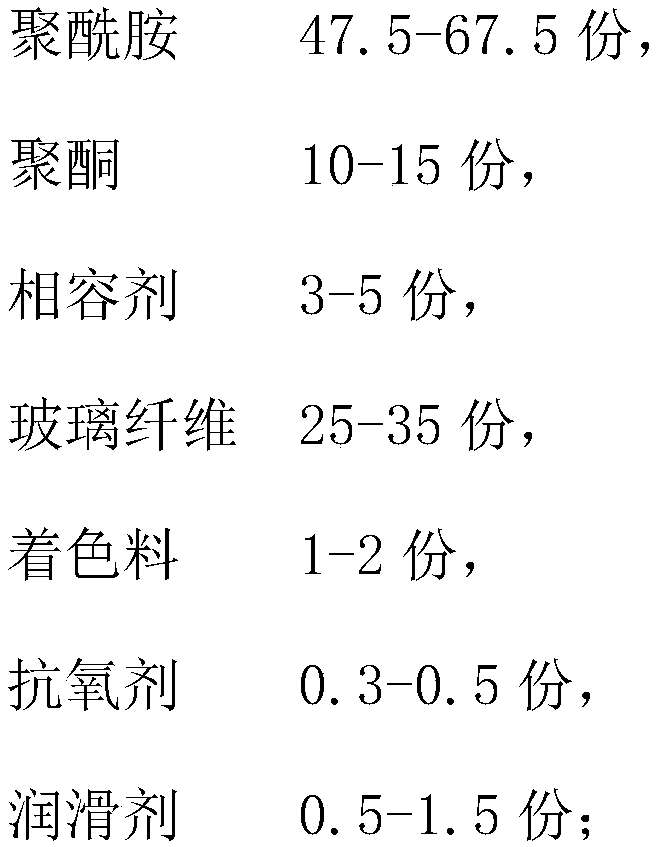

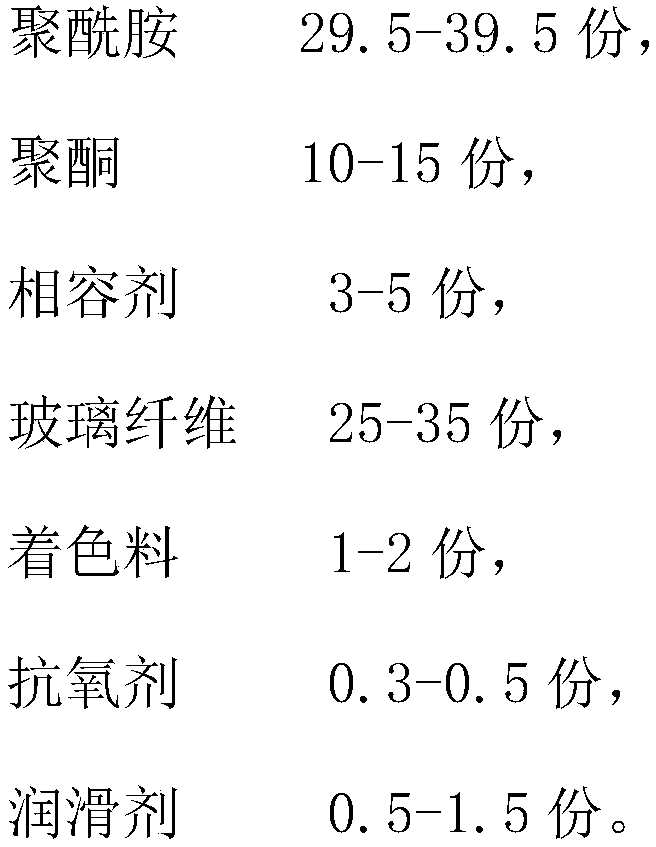

Method used

Image

Examples

Embodiment 1

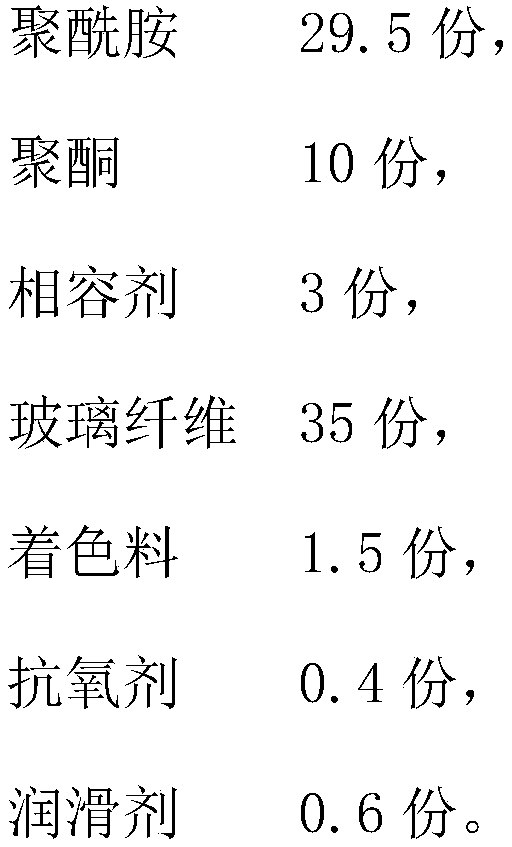

[0042] This embodiment provides a nylon / POK alloy with good surface, high impact and warpage resistance and its preparation method.

[0043] The raw material formula of this nylon / POK alloy is shown in Table 1. The preparation method of this nylon / POK alloy comprises the steps:

[0044] 34.5 parts of pretreated PA66 resin, 20 parts of PA66 / 6 resin, 10 parts of POK resin, 3 parts of compatibilizer (Mitsubishi, S2200), 1.5 parts of nigrosine (Langyu, T5011), antioxidant (1010 and 168 mass ratio 1:1) 0.4 parts, lubricant (MB50-001 and montan wax mass ratio 1:1) 0.6 parts, add to the high-speed mixer in proportion and stir for 2-4 minutes, mix well;

[0045] Put the mixed material into the twin-screw extruder, and at the same time of melt extrusion, side feed the chopped fiber (polystone 568H, 30 parts) to extrude, the melt extrusion temperature is between 240-260 ℃, the screw The speed is 450-500 rpm;

[0046] The extruded material was cooled, air-dried, pelletized, and subjec...

Embodiment 2

[0048] This embodiment provides a nylon / POK alloy with good surface, high impact and warpage resistance and its preparation method.

[0049]The raw material formula of this nylon / POK alloy is shown in Table 1. The preparation method of this nylon / POK alloy comprises the steps:

[0050] 34.5 parts of pretreated PA66 resin, 20 parts of PA66 / 6 resin, 10 parts of POK resin, 3 parts of compatibilizer (Mitsubishi, S2200), 1.5 parts of nigrosine (Langyu, T5011), antioxidant (1010 Add 0.4 part of 168 mass ratio (1:1) and 0.6 part of lubricant (MB50-001 and montan wax mass ratio 1:1) to the high-speed mixer in proportion and stir for 2-4 minutes, and mix well;

[0051] Put the mixed material into the twin-screw extruder, and at the same time of melt extrusion, side-feed flat glass fiber (Chongqing International 301HP-M4, 30 parts) to extrude, and the temperature of melt extrusion is between 240-260°C , the screw speed is 450-500 rpm;

[0052] The extruded material was cooled, air-dr...

Embodiment 3

[0054] This embodiment provides a nylon / POK alloy with good surface, high impact and warpage resistance and its preparation method.

[0055] The raw material formula of this nylon / POK alloy is shown in Table 1. The preparation method of this nylon / POK alloy comprises the steps:

[0056] 39.5 parts of pretreated PA66 resin, 20 parts of PA66 / 6 resin, 10 parts of POK resin, 3 parts of compatibilizer (Mitsubishi, S2200), 1.5 parts of nigrosine (Langyu, T5011), antioxidant (1010 and 168 mass ratio 1:1) 0.4 parts, lubricant (MB50-001 and montan wax mass ratio 1:1) 0.6 parts, add to the high-speed mixer in proportion and stir for 2-4 minutes, mix well;

[0057] Put the mixed material into the twin-screw extruder, and at the same time of melt extrusion, side-feed flat glass fiber (Chongqing International 301HP-M4, 25 parts) to extrude, and the temperature of melt extrusion is between 240-260°C , the screw speed is 450-500 rpm;

[0058] The extruded material was cooled, air-dried, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal deformation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com