Color ink for packaging and preparation method thereof

A color ink and packaging technology, applied in the direction of ink, application, household appliances, etc., can solve the problems of slow drying speed and high chemical content, and achieve the effect of fast drying speed, low chemical content and high adhesion fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

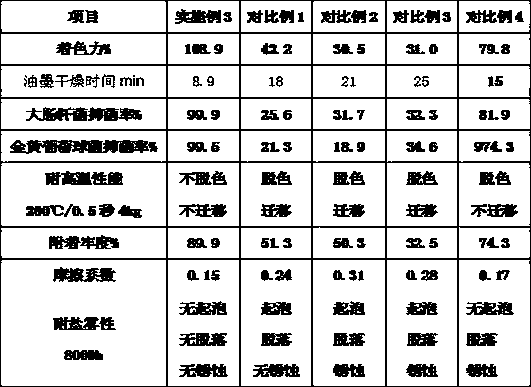

Examples

Embodiment 1

[0025] A kind of color ink for packaging, the color ink for packaging includes the following raw materials in parts by weight: 12 parts of water-based polyester resin, 5 parts of persimmon tannin, 10 parts of activated snail powder, polysilicic aluminum sulfate 15 parts, 5 parts of L-carnitine, 15 parts of modified starch, 1 part of pigment, 55 parts of deionized water; the activated snail powder is prepared by the following method: after shelling the snail, soak it in citric acid solution for 5 hours , and then placed in freezing at minus 78°C for 20 hours, then steamed the frozen snail meat in steam at 120°C for 1 hour, then dried the steamed snail meat, crushed it, and mixed it with sodium carbonate at a ratio of 1:0.3, Place it at 100°C and bake for 20 minutes, take it out, grind and sieve 100 meshes to get it; the preparation method of the modified starch is: mix the starch and activated snail powder at a ratio of 1:0.1, add 60 parts of water, and cook for 20 minutes. Ins...

Embodiment 2

[0034] A kind of color ink for packaging, the color ink for packaging includes the following raw materials in parts by weight: 45 parts of water-based polyester resin, 10 parts of persimmon tannin, 35 parts of activated snail powder, polysilicic aluminum sulfate 25 parts, 16 parts of L-carnitine, 28 parts of modified starch, 3 parts of pigment, and 85 parts of deionized water; the activated snail powder is prepared by the following method: after shelling the snail, soak it in citric acid solution for 10 hours , and then placed in freezing at minus 78°C for 40 hours, then steamed the frozen snail meat in steam at 125°C for 2 hours, then dried the steamed snail meat, crushed it, and mixed it with sodium carbonate at a ratio of 1:0.3, Place it at 115°C and bake for 40 minutes, take it out, grind and sieve 200 meshes to get it; the preparation method of the modified starch is: mix the starch and activated snail powder at a ratio of 1:0.1, add 80 parts of water, and cook for 30 minu...

Embodiment 3

[0043] A kind of colored ink for packaging, said colored ink used for packaging includes the following raw materials in parts by weight: 35 parts of water-based polyester resin, 7 parts of persimmon tannin, 28 parts of activated snail powder, polysilicic aluminum sulfate 22 parts, L-carnitine 11 parts, modified starch 22 parts, pigment 2 parts, deionized water 74 parts. The activated snail powder is prepared by the following method: remove the shells of the snails, soak them in a citric acid solution for 8 hours, then freeze them at minus 78°C for 28 hours, and place the frozen snail meat in a 122°C steam Medium-steam for 1.3h, then dry the steamed snail meat, grind it, mix it with sodium carbonate at a ratio of 1:0.3, place it at 108°C for 32 minutes, take it out, grind it and sieve it through a 150-mesh sieve. The preparation method of the modified starch is as follows: mix the starch and the activated snail powder at a ratio of 1:0.1, add 70 parts of water, and cook for 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com