CoVGa base Heusler alloy for realizing magnetic field driving metamagnetism reverse martensite phase transformation

A martensitic phase transformation and magnetic field-driven technology, applied in the field of Heusler alloys, can solve problems such as poor mechanical properties, limited magneto-caloric materials, and fragility, and achieve good machinability, wide application fields, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

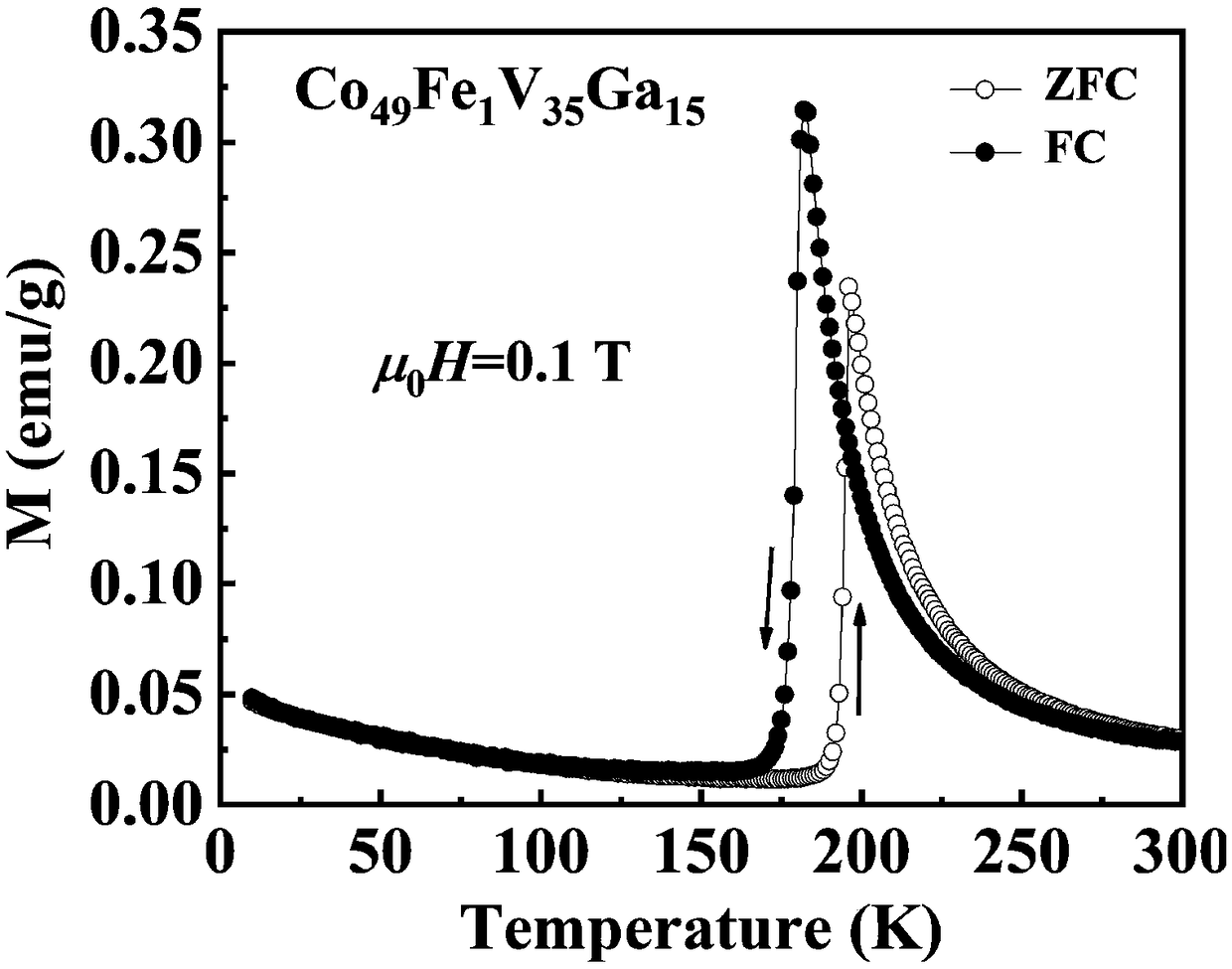

[0039] Example 1 In order to satisfy the first general chemical formula Co of the alloy 50-x Fe x V 35 Ga 15 , x takes 1.

[0040] This embodiment is an alloy Co with a magnetically variable martensitic transformation 49 Fe 1 V 35 Ga 15 , according to the stoichiometric ratio to calculate the required mass of Co, Fe, V, Ga elements for batching, it needs to be accurate to 0.1mg ~ 0.01mg, and the purity of the metal elements is above 99.95%. Put the prepared raw materials into the water-cooled copper crucible arc melting furnace, and pump the vacuum to 5×10 -3 Above Pa, fill with argon gas with a purity of 99.999% at 1 atmospheric pressure for arc melting.

[0041] For the first smelting, use 23A current to melt the metal. When you see the metal liquid flowing in the crucible, turn over the block sample smelted in the first smelting, slightly increase the current to 40A and smelt it 4 times, and you can get Co 49 Fe 1 V 35 Ga 15 Alloy ingots; put part of the alloy i...

Embodiment 2

[0042] Example 2 The first general chemical formula of the alloy Co 50-x Fe x V 35 Ga 15 , x takes 5.

[0043] This embodiment is an alloy Co with magnetic field-driven metamagnetic martensitic transformation 45 Fe 5 V 35 Ga 15 , the specific preparation method of the bulk alloy is almost the same as the preparation process of Example 1, the difference is that part of the Co 45 Fe 5 V 35 Ga 15 The alloy ingot is put into a quartz tube with an inner diameter of 10 mm, and then the quartz tube is placed in a high vacuum belt furnace, and the furnace cavity is evacuated to 10 mm. -4 Pa, 0.5 atmospheric pressure of argon gas is introduced, the ingot is melted into a liquid state through high-frequency induction heating, and then sprayed onto the high-speed rotating copper rod through the small hole at the bottom of the quartz tube, and the speed of the copper rod is 10-50m / s , to obtain a fast-quenched strip sample; put the strip sample into a quartz tube with an inner ...

Embodiment 3

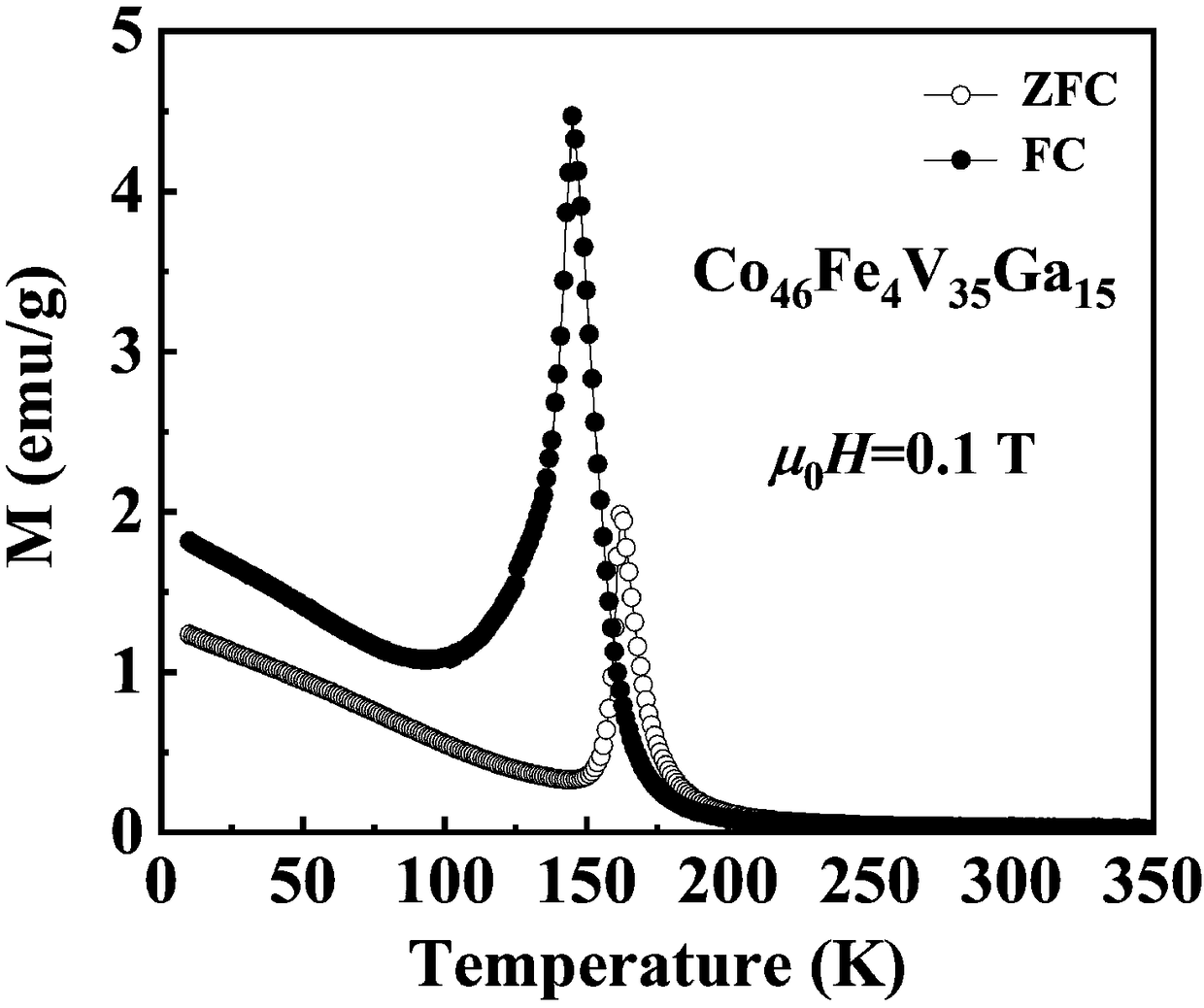

[0044] Example 3 The first general chemical formula of the alloy Co 50-x Fe x V 35 Ga 15 , x takes 4.

[0045] This embodiment is an alloy Co with a magnetic field-driven metamagnetic martensitic transformation 46 Fe 4 V 35 Ga 15 , the specific preparation method of the sample is the same as the preparation process of Example 1, the only difference is that according to Co 46 Fe 4 V 35 Ga 15 The stoichiometric ratio is used to calculate the mass of the required Co, Fe, V, and Ga elements for batching; the annealing temperature is 1200 ° C, and the time is 24 hours. in Co 46 Fe 4 V 35 Ga 15 The temperature-driven severe metamagnetic martensitic phase transformation is obtained in the alloy sample, and phase transformation retardation occurs at low temperature. The thermomagnetic curve of the alloy sample under a 0.1T magnetic field is shown in the attached figure 2 shown. It can be seen that the alloy undergoes a severe martensitic transformation between 125-160...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com