Rare earth 34Mn2VRE-containing rolled square billet for gas cylinder and manufacturing method of square billet

A technology for rolling billets and rare earths, which is applied in the field of rolling billets containing rare earth 34Mn2VRE for gas cylinders and their manufacturing fields, and can solve the problems of cleanliness of molten steel, poor product quality and high material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

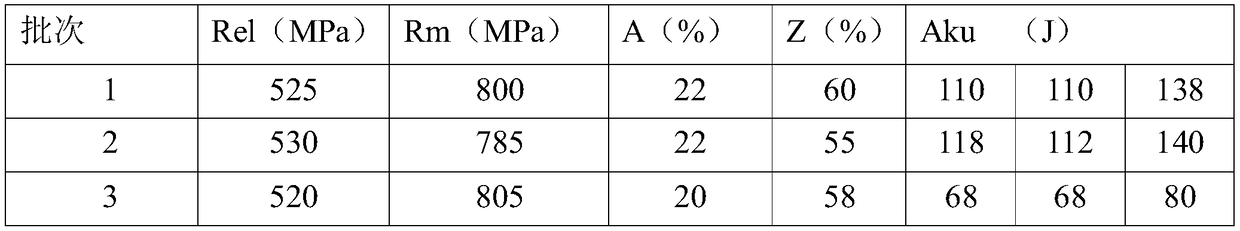

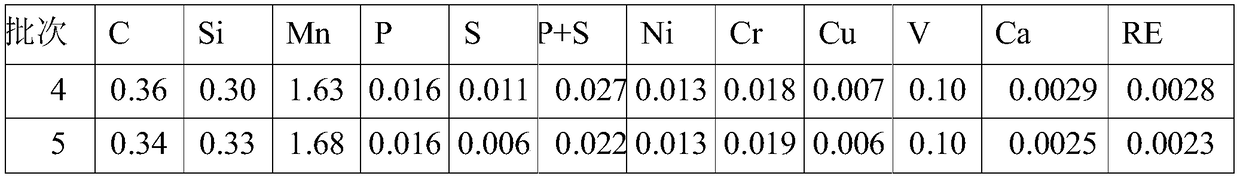

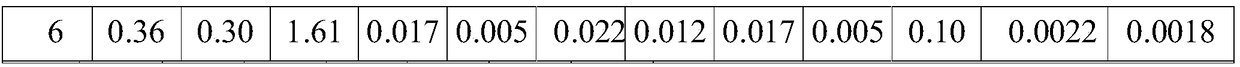

Examples

Embodiment 1

[0098] 1. The blast furnace molten iron is pretreated so that the S content (percentage by weight) in the molten iron is reduced to below 0.010%;

[0099] 2. Mix the pretreated molten iron into the top-bottom combined blowing converter, add (weight percentage) 10% high-quality scrap steel, adopt single slag process to smelt, control the final slag basicity and end target, and carry out deoxidation alloying during the tapping process. The final deoxidation adopts the aluminum deoxidation process, the slag must be blocked or removed during the tapping process, and the lime block is added after the alloy is added during the tapping process;

[0100] 3. Refining in LF furnace and adding VFe alloy: during the whole refining process, argon is blown normally as required, and the temperature is raised by gradually increasing the heating rate from low-level to high-level; according to the composition and temperature of molten steel in the converter, slag desulfurization and composition ...

Embodiment 2

[0115] 1. The blast furnace molten iron is pretreated so that the S content (percentage by weight) in the molten iron is reduced to below 0.010%;

[0116] 2. Mix the pretreated molten iron into the top-bottom combined blowing converter, add (weight percentage) 10% high-quality scrap steel, adopt single slag process to smelt, control the final slag basicity and end target, and carry out deoxidation alloying during the tapping process. The final deoxidation adopts the aluminum deoxidation process, the slag must be blocked or removed during the tapping process, and the lime block is added after the alloy is added during the tapping process;

[0117] 3. Refining in LF furnace and adding VFe alloy: during the whole refining process, argon is blown normally according to the requirements, and the temperature is raised by gradually increasing the heating rate from low-level to high-level; according to the composition and temperature of converter molten steel, slag desulfurization and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com