Preparation method of nano silver colloid and method for detecting hexazinone by using silver colloid

A technology of nano silver glue and cycloazinone, applied in the field of detection, can solve the problems of long time consumption, complicated pretreatment and high cost, and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

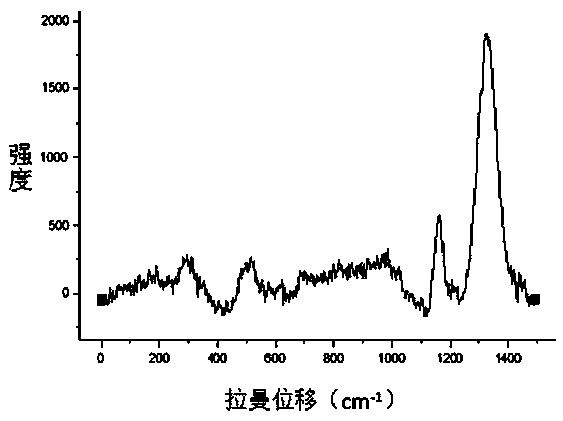

Examples

Embodiment 1

[0045] (1) Pretreatment of copper sheet:

[0046] Cut the copper sheet into a 2cm×5cm rectangular small copper sheet, soak it in acetone, ethanol and ultrapure water for 10 minutes, and finally soak the copper sheet in 0.1mol / L HNO 3 Remove the oxide film on the surface; finally rinse with ultrapure water and dry at room temperature.

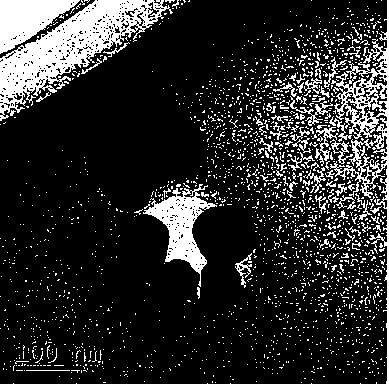

[0047] (2) Copper plated with nano-silver

[0048]Put the copper sheet in 0.02mol / L SnCl 2 and 0.02mol / L hydrochloric acid mixed solution for 1min, and dry at room temperature; secondly, the copper sheets were sequentially immersed in 0.01mol / L AgNO 3 Soak in a mixed solution with 0.5% hydroxyethyl cellulose for 5 minutes, and dry at room temperature; repeat the above steps once, and finally put the copper sheet in the SnCl 2 Soak in the solution for 1min, rinse with ultrapure water.

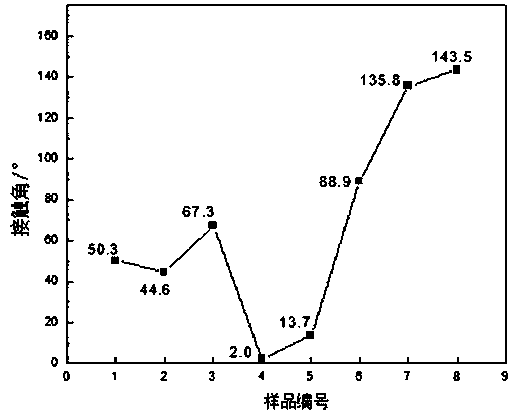

[0049] (3) Grafted mercapto compound

[0050] The prepared nano-silver-coated metal copper sheet was prepared at 1.0×10 -3 mol / L n-butanethiol ethanol solut...

Embodiment 2

[0064] (1) Pretreatment of copper sheet:

[0065] Cut the copper sheet into 2cm×5cm rectangular small copper sheet, soak in acetone, ethanol and ultra-pure water for 10min, and finally soak the copper sheet in 0.3mol / L HNO 3 Remove the oxide film on the surface; finally rinse with ultrapure water and dry at room temperature.

[0066] (2) Copper plated with nano-silver

[0067] Put the copper sheet in 0.04mol / L SnCl 2 and 0.03mol / L hydrochloric acid mixed solution for 4min, and dry at room temperature; secondly, the copper sheets were successively immersed in 0.01mol / L AgNO 3 Soak in a mixed solution with 0.5% hydroxyethyl cellulose for 5 minutes, and dry at room temperature; repeat the above steps once, and finally put the copper sheet in the SnCl 2 Soak in the solution for 1min, rinse with ultrapure water.

[0068] (3) Grafted mercapto compound

[0069] The prepared nano-silver-coated metal copper sheet was prepared at 1.0×10 -3 mol / L n-dodecanethiol ethanol solution so...

Embodiment 3

[0083] (1) Pretreatment of copper sheet:

[0084] Cut the copper sheet into 2cm×5cm rectangular small copper sheet, soak in acetone, ethanol and ultrapure water for 20min, and finally soak the copper sheet in 0.5mol / L HNO 3 Remove the oxide film on the surface; finally rinse with ultrapure water and dry at room temperature.

[0085] (2) Copper plated with nano-silver

[0086] Put the copper sheet in 0.05mol / L SnCl 2 and 0.05mol / L hydrochloric acid mixed solution for 7min, and dry at room temperature; secondly, the copper sheets were successively immersed in 0.01mol / L AgNO 3 Soak in a mixed solution with 0.5% hydroxyethyl cellulose for 5 minutes, and dry at room temperature; repeat the above steps once, and finally put the copper sheet in the SnCl 2 Soak in the solution for 1min, rinse with ultrapure water.

[0087] (3) Grafted mercapto compound

[0088] The prepared nano-silver-coated metal copper sheet was prepared at 1.0×10 -2 mol / L n-octadecylmercaptan ethanol solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com