Preparation method of 1, 3-butylene glycol

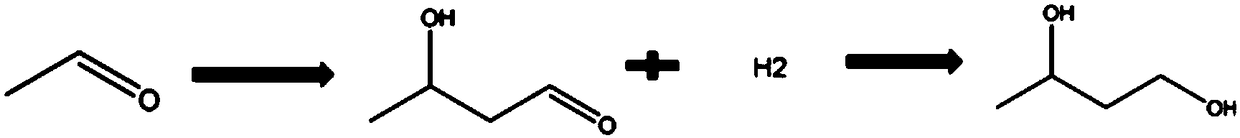

A technology of butanediol and acetaldehyde, which is applied in the chemical industry, can solve the problems of pungent odor, unsatisfactory yield and purity of 1,3-butanediol, etc., achieve high reaction conversion rate and yield, and overcome product Poor quality, avoid the effect of deep condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

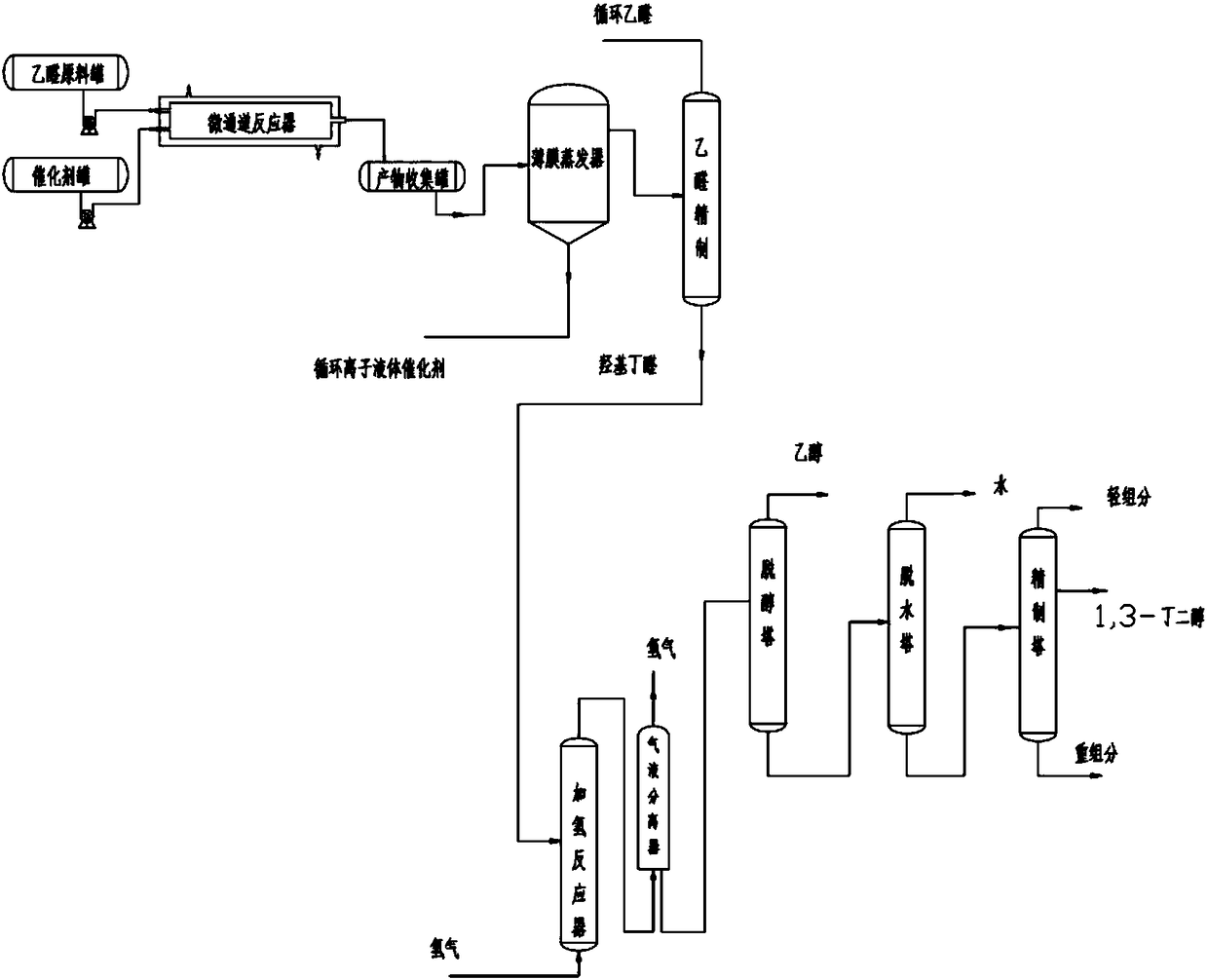

Method used

Image

Examples

Embodiment 1

[0039] (1) After acetaldehyde and water are mixed evenly according to the mass ratio of about 8:1, transport them to the material pretreatment tank, keep the temperature at 15°C, and carry out under the protection of nitrogen;

[0040] (2) Constant temperature of alkaline ionic liquid catalyst hydroxide 1-butyl-3-methylimidazolium salt to 15°C;

[0041] (3) acetaldehyde solution and ionic liquid catalyst in step (1), (2) are sent in the microchannel reactor;

[0042] (4) In the microchannel reactor, the acetaldehyde aqueous solution undergoes an aldol condensation reaction under the catalysis of an ionic liquid catalyst. The process controls the reaction temperature to 15° C., the reaction system PH11, and the reaction residence time of 5 minutes to obtain a crude product, mainly including unreacted Acetaldehyde (about 10% to about 20%), 3-hydroxybutyraldehyde (about 70% to 80%), a small amount of crotonaldehyde (about 0.3% to 0.5%), other impurities and water;

[0043] (5) S...

Embodiment 2

[0050] (1) After acetaldehyde and water are mixed evenly according to the mass ratio of about 9:1, transport them to the material pretreatment tank, keep the temperature at 20°C, and carry out under the protection of nitrogen;

[0051] (2) Constant temperature of alkaline ionic liquid catalyst hydroxide 1-butyl-3-methylimidazolium salt to 20°C;

[0052] (3) acetaldehyde solution and ionic liquid catalyst in step (1), (2) are sent in the microchannel reactor;

[0053] (4) In the microchannel reactor, the acetaldehyde aqueous solution undergoes an aldol condensation reaction under the catalysis of an ionic liquid catalyst. The process controls the reaction temperature to 20° C., the reaction system pH to 11.4, and the reaction residence time to 10 minutes to obtain a crude product, mainly containing Reaction of acetaldehyde (about 10% to about 20%), 3-hydroxybutyraldehyde (about 70% to 80%), a small amount of crotonaldehyde (about 0.3% to 0.5%), other impurities and water;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com