Matte lip glaze and preparation process thereof

A lip glaze and matte technology, which is applied in the field of matte lip glaze and its preparation process, can solve the problems of not easy to fade, not easy to take off makeup, damage, etc., and achieve the effect of prolonging the shelf life, good durability, and high chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

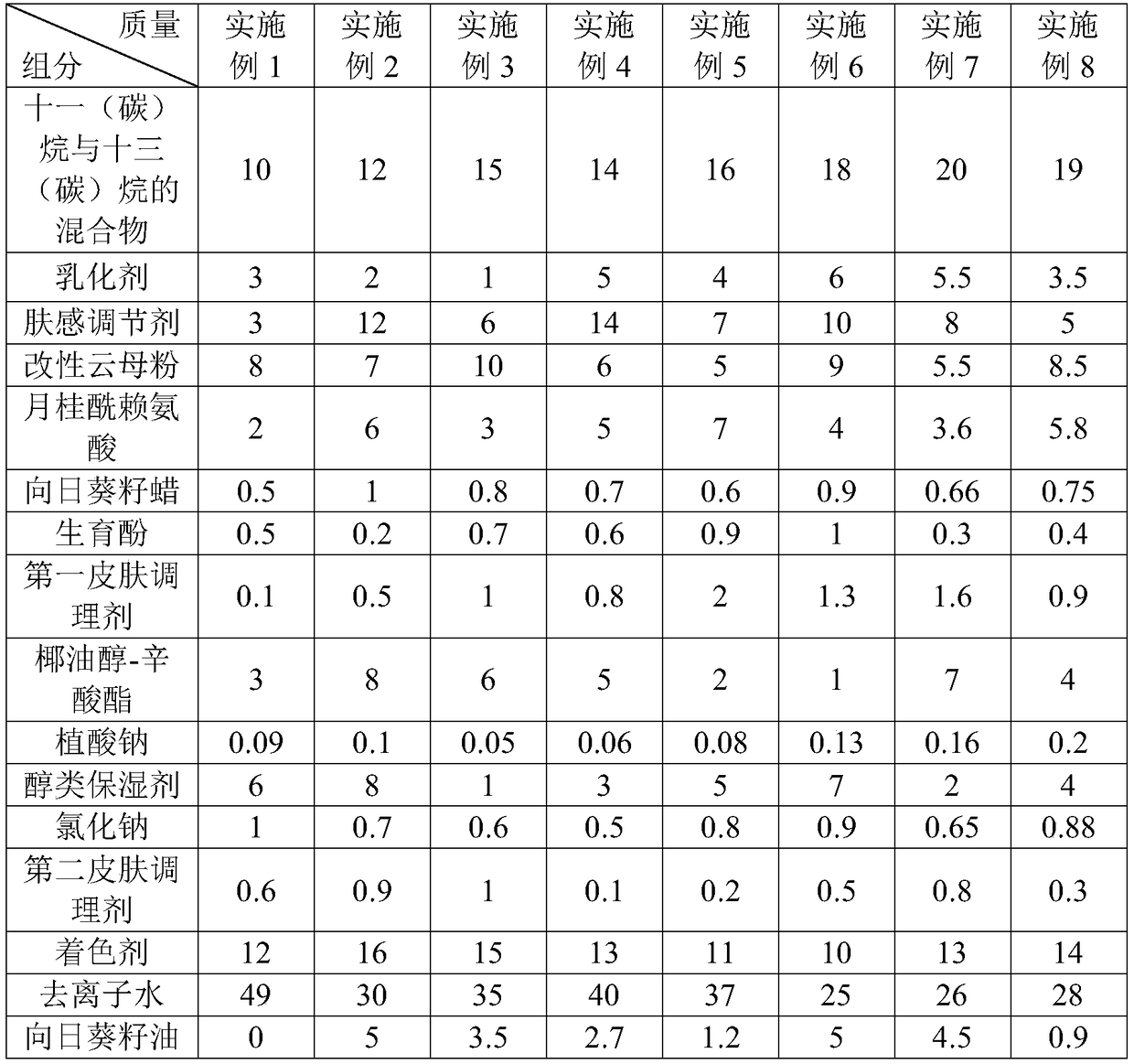

[0077] Embodiment 1: A kind of matte lip glaze, the components included and the corresponding quality thereof are shown in Table 1, and are prepared through the following steps:

[0078] Step 1, the mixture of undecane and tridecane, emulsifier, skin feel modifier, modified mica powder (UNI-MICA 1250LL) with a water contact angle of 138.52°, lauroyl lysine acid, sunflower seed wax, vegetable oil humectant, tocopherol, first skin conditioner, cocoyl-caprylate heated to 65°C and kept warm to form a first mixture;

[0079] heating deionized water, sodium stearyl glutamate, sodium phytate, alcohol moisturizer, and sodium chloride to 65°C and keeping it warm to form a second mixture;

[0080] Heat the colorant to 70°C and keep it warm;

[0081] thoroughly mixing the preservative, the second skin conditioning agent, and the fragrance to form a third mixture;

[0082] Step 2: mix the heat-preserved coloring agent with the first mixture and homogenize it into a state of uniform text...

Embodiment 2-8

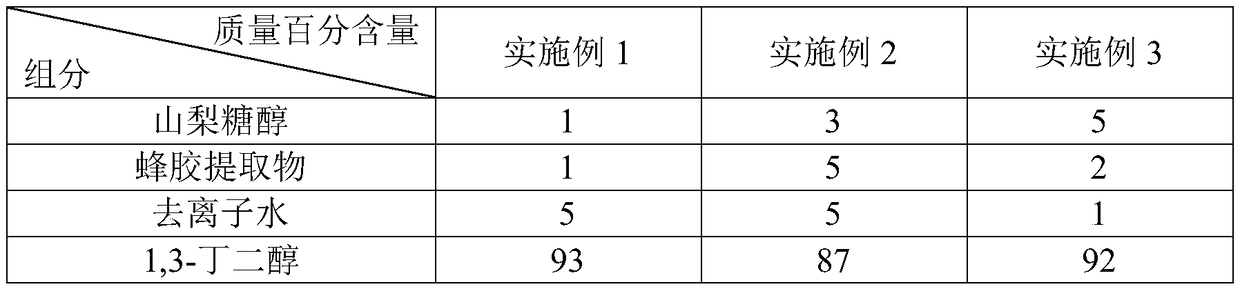

[0091] Embodiment 2-8: a matte lip glaze, the difference from embodiment 1 is that the components included and their corresponding qualities are shown in Table 1.

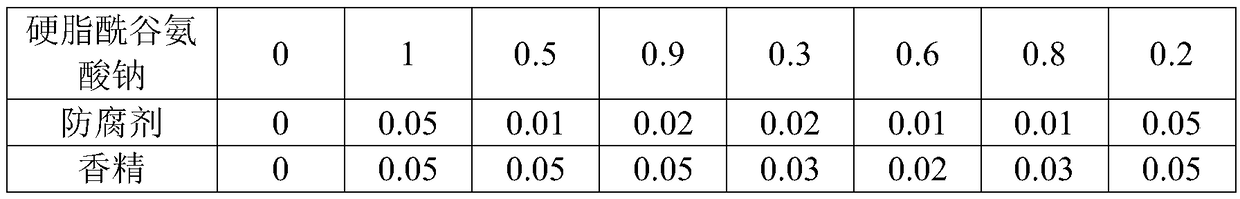

[0092] Table 2 shows the mass percent content of each component in the first skin conditioner in Example 2-3.

[0093] In embodiment 2, the mixture of undecane and tridecane consists of 50wt% undecane, 500ppm tocopherol, 20ppm sunflower seed oil, tridecane in the remaining mass percentage (carbon) alkane composition; the particle diameters of modified mica powder and mica powder are 800 mesh and 1000 mesh respectively, and the water contact angle of modified mica powder UNI-MICA 1250LL is 138.52°.

[0094] In embodiment 3, the mixture of undecane and tridecane consists of 60wt% undecane, 400ppm tocopherol, 25ppm sunflower seed oil, tridecane in the remaining mass percentage (carbon) alkane composition. The particle sizes of modified mica powder and mica powder are 1000 mesh and 2000 mesh respectively, and the wat...

Embodiment 9

[0100] Embodiment 9: A matte lip gloss, the difference from embodiment 1 is that the emulsifier is sorbitan sesquioleate and sorbitan trioleate with a mass ratio of 1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com