A welding seam processing equipment for steel plate welding with the function of mobile grinding and spraying anti-corrosion paint

A technology for processing equipment and anti-corrosion paint, applied in metal processing equipment, grinding/polishing equipment, grinding machine parts, etc. The effect of labor volume, work efficiency improvement, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

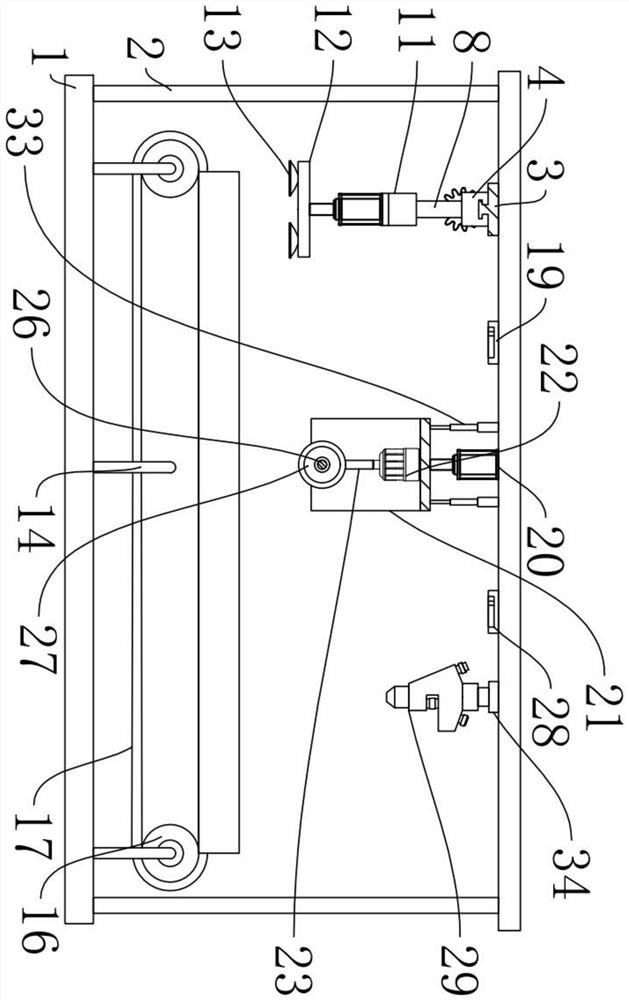

Image

Examples

Embodiment

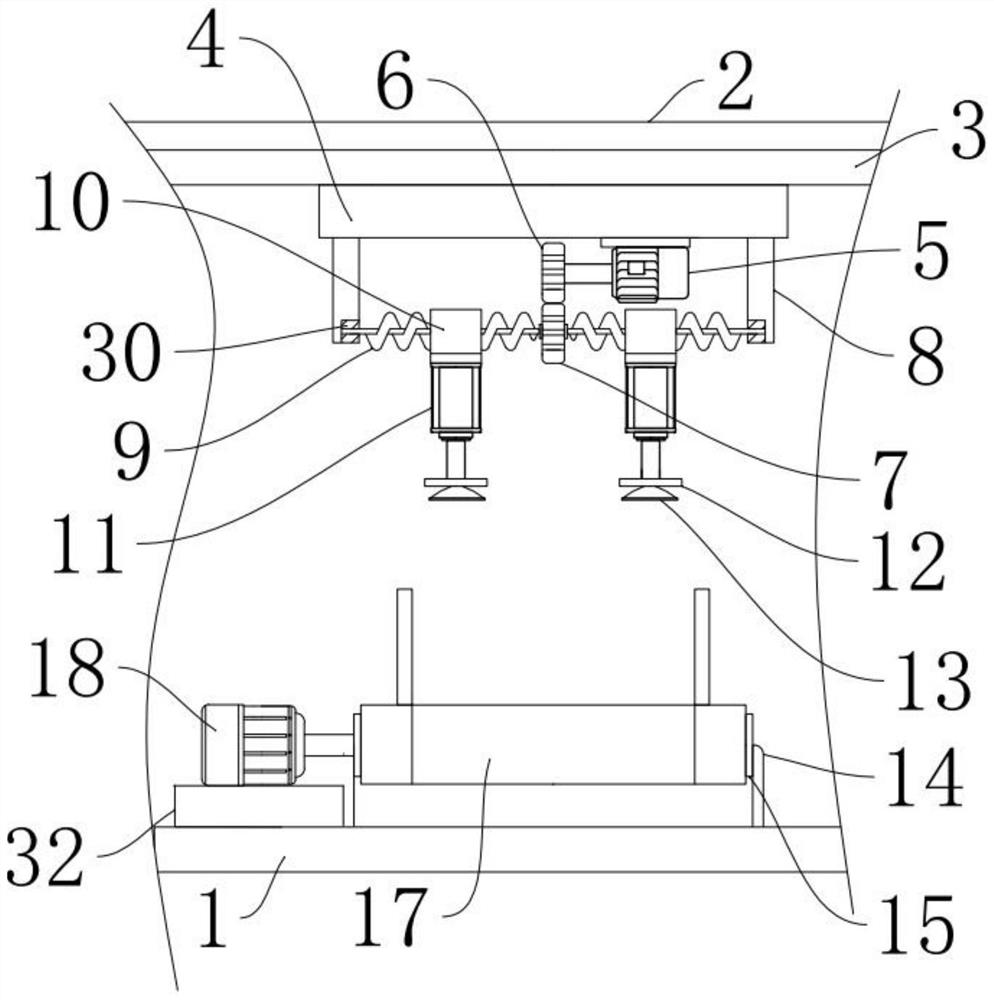

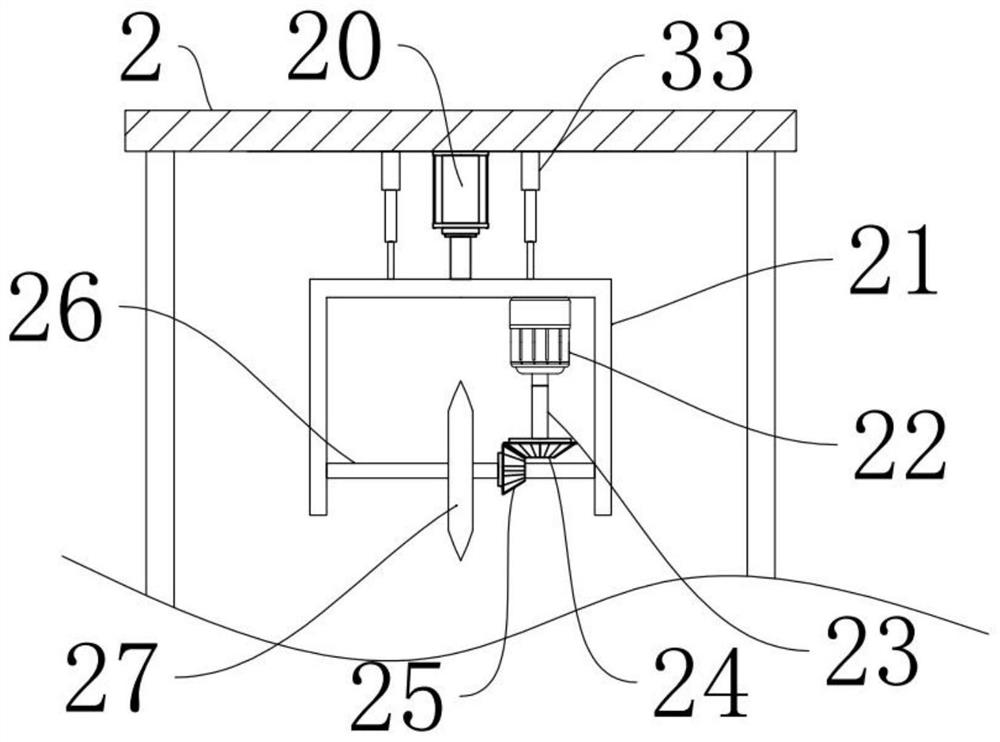

[0055] Embodiment: When in use, turn on the power, and the electric slider 4 slidingly fitted on the electric slide rail 3 receives the signal from the driver, and the electric slider 4 starts to move, and when it moves above the steel plate, it stops moving and is placed The electric push rod 11 on the lower wall of the movable block 10 receives the signal from the driver, and the driving end begins to extend, synchronously driving the horizontal plate 12 and the suction cup 13 under the horizontal plate 12 to move downward. When touching the steel plate, the driving end Stop elongation, the first servo motor 5 placed on the lower wall of the electric slider 4 receives the signal from the driver, the driving end starts to rotate counterclockwise, and the main gear 6 placed at the driving end of the first servo motor 5 synchronously drives the auxiliary gear meshed with it. The gear 7 and the threaded rod 9 embedded in the pinion 7 rotate synchronously. At this time, a pair of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com