Hot stamping high strength steel automobile body covering part and manufacturing method and system thereof

A technology of automobile body and manufacturing method, which is applied to vehicle parts, transportation and packaging, etc., which can solve the problems that the performance is difficult to meet the demand, and achieve the effect of excellent mechanical performance, beautiful appearance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

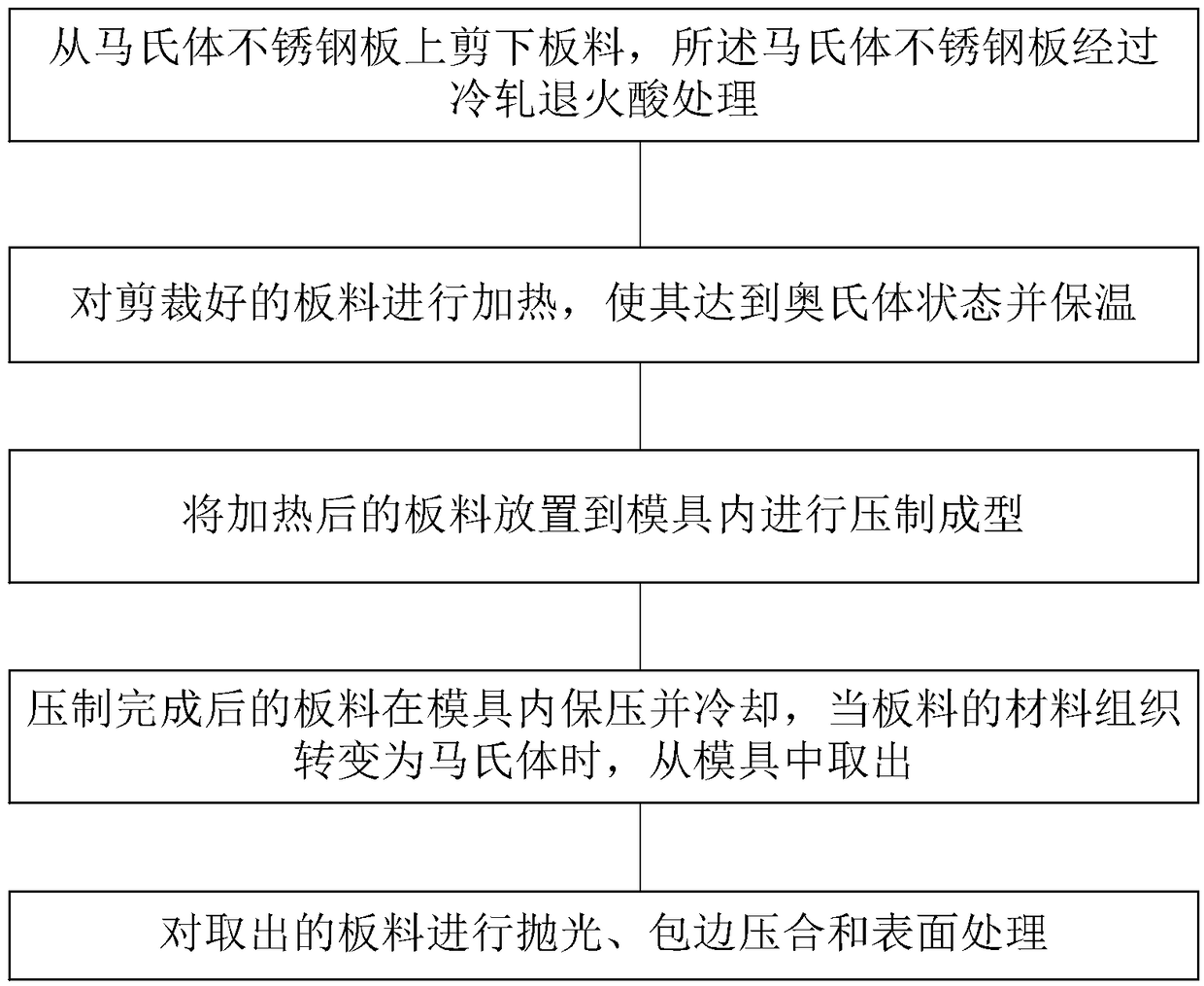

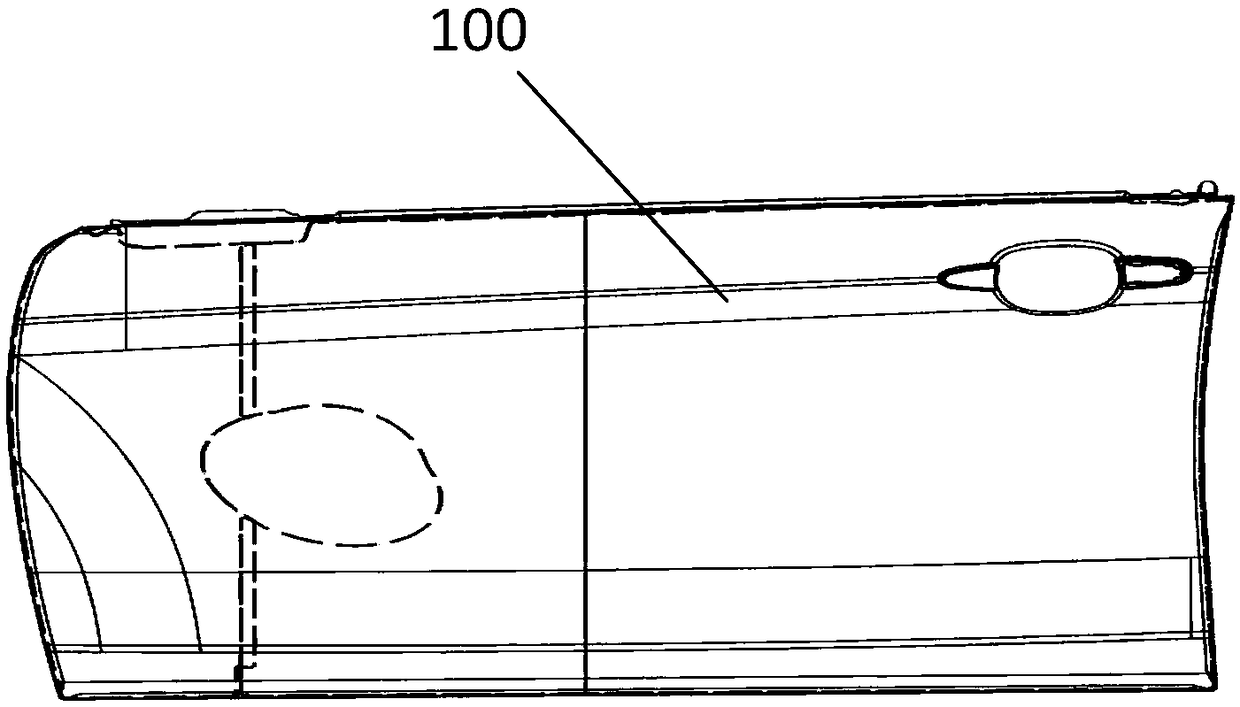

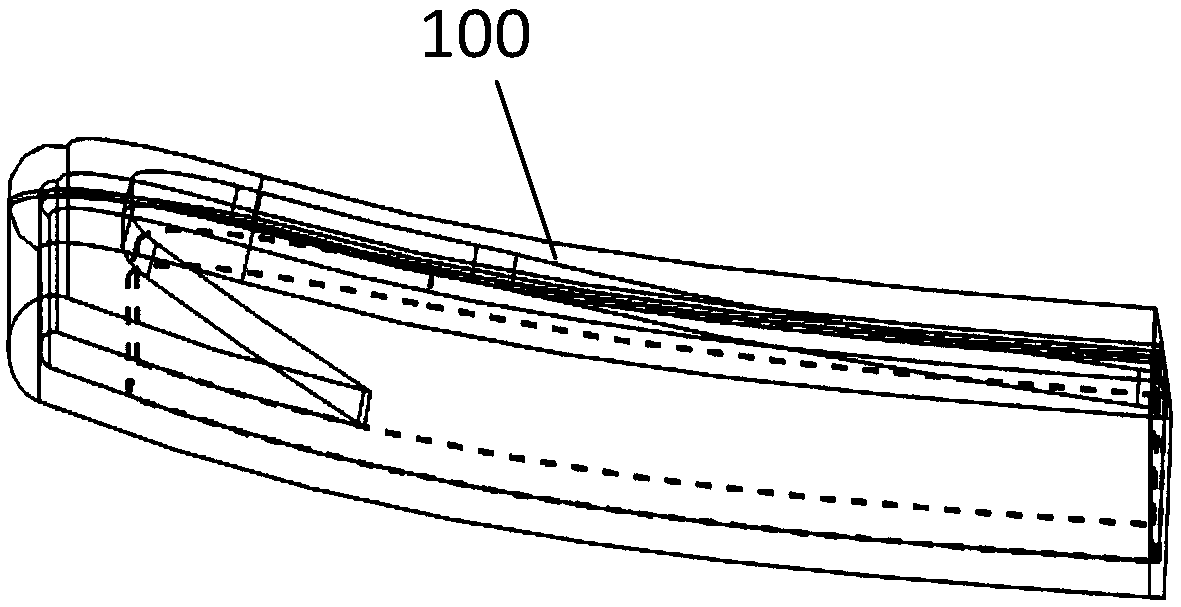

[0040] The part that the present embodiment needs to prepare is integral type car door panel 100, and structure is as follows Figure 1-2 shown.

[0041] First, a 3Cr13 martensitic stainless steel plate with a thickness of 0.55mm and cold-rolled, annealed and pickled, with a martensitic transformation temperature of 230°C, contains C: 0.32%, Si: 0.3%, Mn: 0.3%, Cr: 13%, Ni: 0.6%;

[0042] Then, put the cut sheet into the heating furnace to heat to 1050°C and keep it warm for 1min;

[0043] Then, put the sheet into the mold for pressing, the time for the sheet to be transferred from the heating furnace to the mold after heating is 6s, the time for the sheet to be placed in the mold to the start of pressing is 1s, and the time from the start of the mold to the end of the mold is 1s;

[0044] Then, the pressed sheet is kept in the mold for 6 seconds, and it is taken out from the mold when the sheet is cooled to close to room temperature and the material structure is transforme...

Embodiment 2

[0049] The parts required to be prepared in this embodiment are also an integral car door panel 100, with a structure such as Figure 1-2 shown.

[0050] First, a martensitic stainless steel plate with a thickness of 0.5mm and cold-rolled, annealed and pickled, with a martensitic transformation temperature of 280°C, contains C: 0.06%, Si: 0.3%, Mn: 1.1%, Cr : 12%, Ni: 0.6%, Nb: 0.5%,;

[0051] Then, put the cut sheet into the heating furnace to heat to 1050°C and keep it warm for 1min;

[0052] Next, put the sheet into the mold of the press for pressing. The time for the sheet to be transferred from the heating furnace to the mold after heating is 6 seconds. The time to the end is 1s;

[0053] Then, the pressed sheet is kept in the mold for 6 seconds, and it is taken out from the mold when the sheet cools close to room temperature;

[0054] Then, use laser heating to heat the flanging area, and then carry out edge-wrapping and pressing with the inner cover. The schematic d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com