Preparation method of high-potential cathode material of lithium ion battery

A positive electrode material and high potential technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance and low potassium content, and achieve the effects of low cost, reduced reaction rate, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

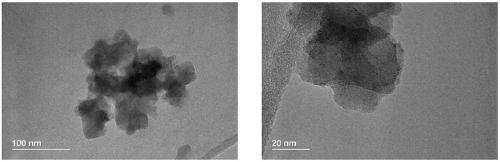

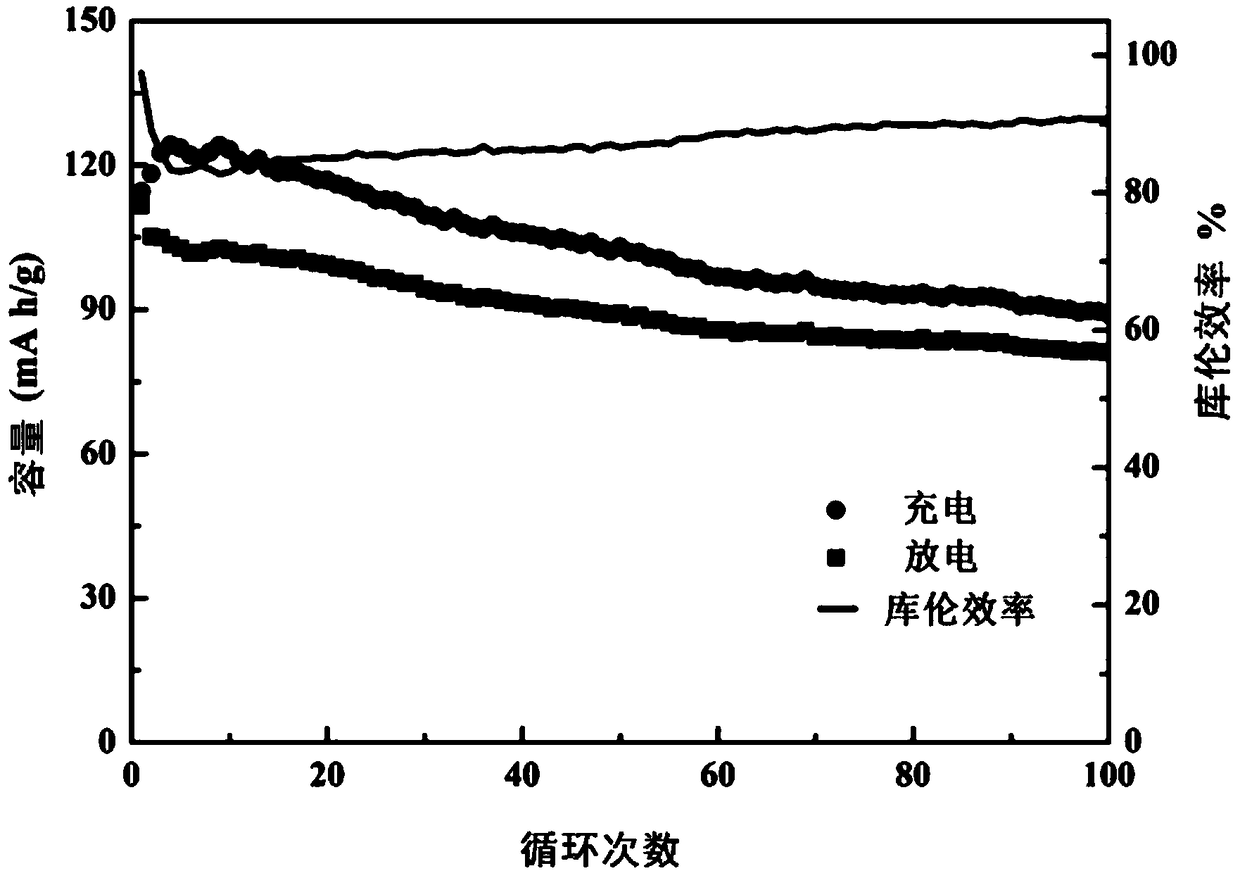

Image

Examples

preparation example Construction

[0030] In an embodiment, a method for preparing a high-potential cathode material for a potassium ion battery includes the following steps:

[0031] Step S1: Add potassium ferrocyanide to deionized water to dissolve to form solution A;

[0032] Step S2, adding iron salt, potassium citrate, citric acid and iron powder as iron sources to deionized water to form a mixed solution B;

[0033] Step S3: Drop the solution A into the mixed solution B and stir continuously;

[0034] Step S4, after the reaction is over, stand still;

[0035] Step S5: Collect the precipitate and dry it.

[0036] Since citric acid and iron powder react to generate hydrogen during the synthesis process, the device spontaneously forms a positive pressure atmosphere to protect the device, avoid oxygen entering the oxidized sample during synthesis, and increase the potassium content and initial capacity of Prussian blue. At the same time, the addition of reducing agents and complexing agents such as citric acid reduces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com