A kind of micronano bioactive glass microsphere with high calcium phosphorus content and preparation method thereof

A technology of bioactive glass and phosphorus content, applied in the field of biomedical materials, can solve the problems of destroying the silicon-oxygen network, unable to obtain dispersive micro-nano bioactive glass, etc., achieving uniform particle size, excellent biomineralization activity, and solving calcium low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

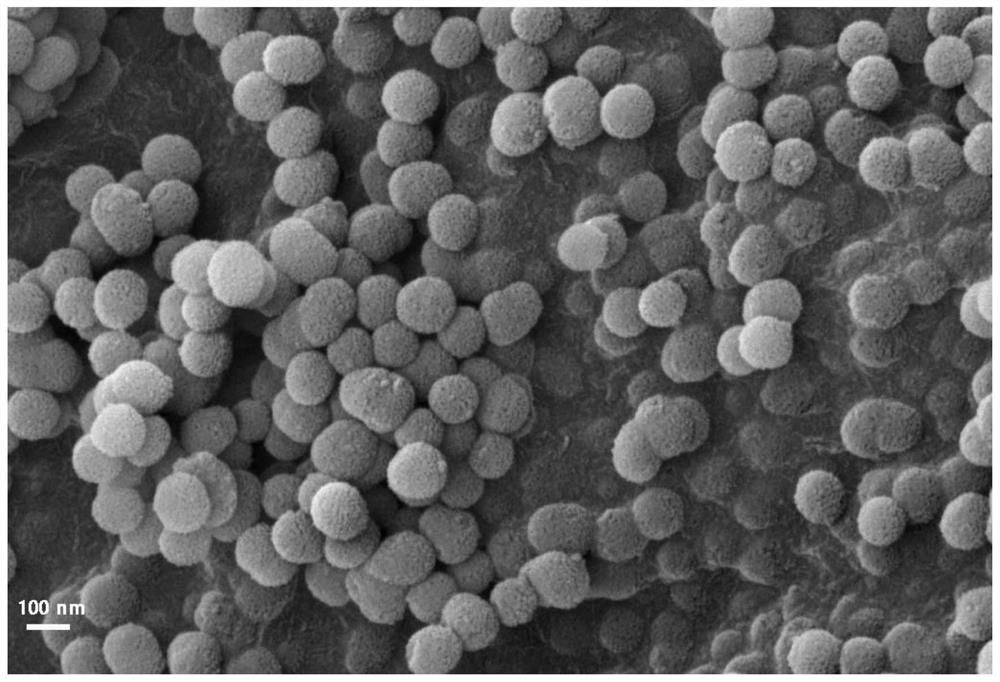

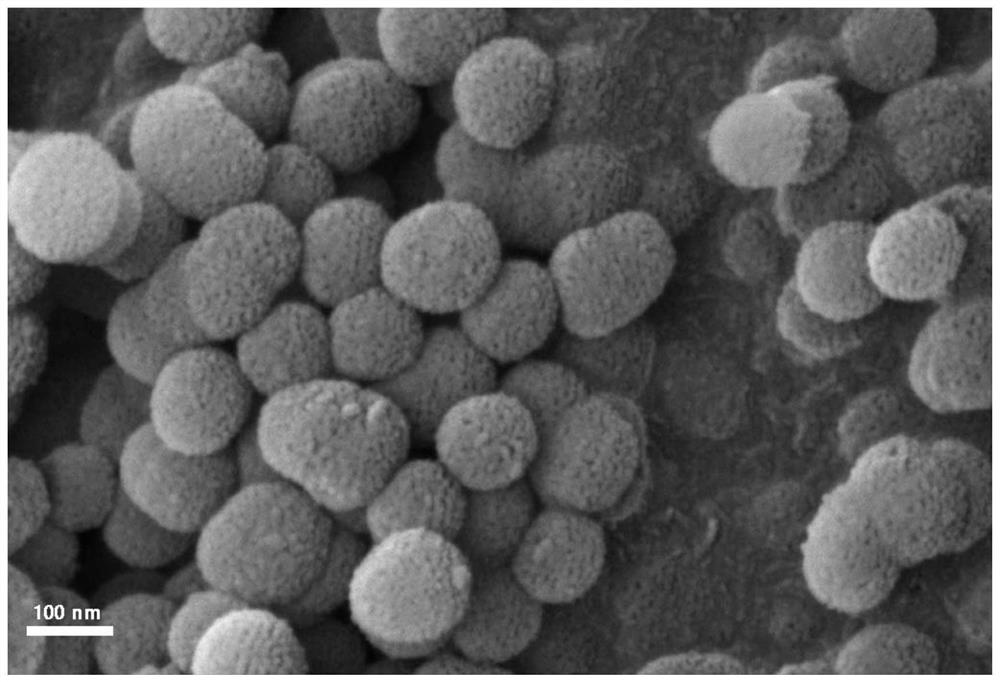

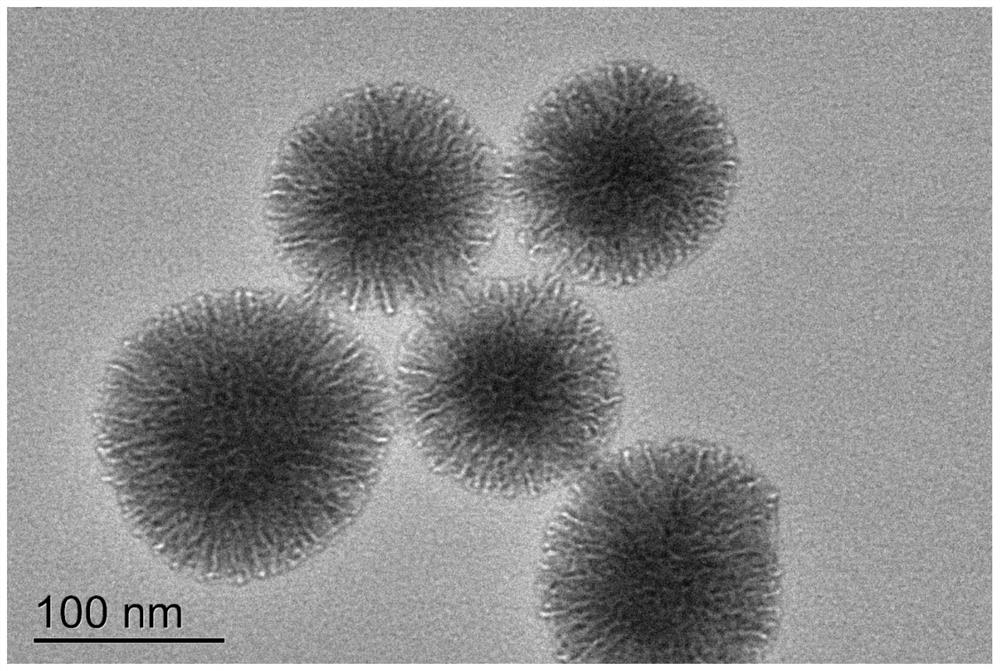

Image

Examples

Embodiment 1

[0038] A method for increasing the content of calcium and phosphorus in bioactive glass, the operation steps are as follows:

[0039] (1) Add 12g of cetyltrimethylammonium bromide and 0.36mL of triethanolamine to 108mL of deionized water in sequence, and stir at 60°C for 1 hour to completely dissolve them to form an aqueous phase solution.

[0040] (2) Add 12mL tetraethyl orthosilicate to 48mL cyclohexane, mix well to form an oil phase solution.

[0041] (3) Add the oil phase solution to the water phase solution dropwise to form a two-phase separation system with upper and lower layers. Stir the lower water phase at a stirring rate of 100 rpm at 60°C. After reacting for 3 hours, add 0.921 mL of triethyl phosphate, The reaction was continued for 9h to obtain a gel solution.

[0042] (4) Centrifuge the gel solution obtained in step (3), wash to obtain a wet gel precipitate, and then place the wet gel in a lyophilizer to freeze-dry for 2 days to obtain a gel powder.

[0043] (5...

Embodiment 2

[0046] A method for increasing the content of calcium and phosphorus in bioactive glass, the operation steps are as follows:

[0047] (1) Add 12g of cetyltrimethylammonium bromide and 0.36mL of triethanolamine to 108mL of deionized water in sequence, and stir at 60°C for 1 hour to completely dissolve them to form an aqueous phase solution.

[0048] (2) Add 12mL tetraethyl orthosilicate to 48mL cyclohexane, mix well to form an oil phase solution.

[0049] (3) Add the oil phase solution to the water phase solution dropwise to form a two-phase separation system with upper and lower layers. Stir the lower water phase at a stirring rate of 150 rpm at 65°C. After reacting for 2.5 hours, add 0.921 mL of triethyl phosphate , and continued to react for 9.5h to obtain a gel solution.

[0050] (4) Centrifuge the gel solution obtained in step (3), wash to obtain a wet gel precipitate, and then place the wet gel in a lyophilizer to freeze-dry for 2 days to obtain a gel powder.

[0051] (...

Embodiment 3

[0054] A method for increasing the content of calcium and phosphorus in bioactive glass, the operation steps are as follows:

[0055] (1) Add 12g of cetyltrimethylammonium bromide and 0.36mL of triethanolamine to 108mL of deionized water in sequence, and stir at 60°C for 1 hour to completely dissolve them to form an aqueous phase solution.

[0056] (2) Add 12mL tetraethyl orthosilicate to 48mL cyclohexane, mix well to form an oil phase solution.

[0057] (3) Add the oil phase solution to the water phase solution dropwise to form a two-phase separation system with upper and lower layers. Stir the lower water phase at a stirring rate of 150 rpm at 60°C. After reacting for 3 hours, add 1.223 mL of triethyl phosphate, The reaction was continued for 9h to obtain a gel solution.

[0058] (4) Centrifuge the gel solution obtained in step (3), wash to obtain a wet gel precipitate, and then place the wet gel in a lyophilizer to freeze-dry for 2 days to obtain a gel powder.

[0059] (5) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com