High-temperature-resistant wave-transparent heat insulation tile and preparation method thereof

A heat-insulating tile and high-temperature-resistant technology, applied in the field of high-temperature-resistant wave-transmitting heat-insulating tile and its preparation, can solve the problem of poor comprehensive performance, inability to meet the requirements for use in the aviation and aerospace fields, and the inability of heat-insulating tile materials to take into account density, strength, Thermal conductivity, wave penetration and other performance issues, to achieve the effects of improved mechanical properties, smooth and delicate appearance, strong design and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

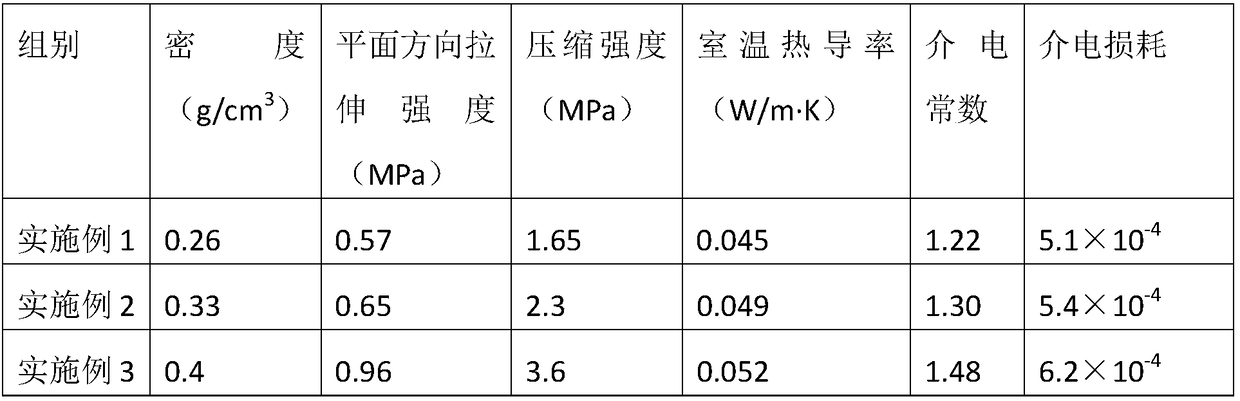

Embodiment 1

[0040] The high-temperature-resistant wave-transmitting thermal insulation tile of this embodiment includes the following components in parts by weight: 70 parts of quartz glass fiber; 25 parts of quartz fiber cotton; 5 parts of sintering aid; 8 parts of starch.

[0041] Wherein, the sintering aid is formed by mixing boron nitride and glass glaze in a weight ratio of 1:5. The diameter of the quartz glass fiber is 1-10um, the length is 2-5mm, SiO 2 Weight content ≥ 99%; the diameter of the quartz fiber cotton is 1-5um, SiO 2 Weight content ≥ 99%.

[0042] Its preparation method is as follows:

[0043] (1) Preparation of sintering aid slurry: take boron nitride, glass glaze and starch in selected parts by weight, disperse them in a solvent, and mix them uniformly to obtain sintering aid slurry; wherein, the solvent is Dehydrated alcohol; The consumption of described dehydrated alcohol is 80 parts;

[0044] (2) Dispersion of fibers: get quartz glass fiber and quartz fiber cot...

Embodiment 2

[0049] The high-temperature-resistant wave-transmitting thermal insulation tile of this embodiment includes the following components in parts by weight: 72 parts of quartz glass fiber; 20 parts of quartz fiber cotton; 8 parts of sintering aid; and 8 parts of starch.

[0050]Wherein, the sintering aid is formed by mixing boron nitride and glass glaze in a weight ratio of 1:4. The diameter of the quartz glass fiber is 1-10um, the length is 2-5mm, SiO 2 Weight content ≥ 99%; the diameter of the quartz fiber cotton is 1-5um, SiO 2 Weight content ≥ 99%.

[0051] Its preparation method is as follows:

[0052] (1) Preparation of sintering aid slurry: take boron nitride, glass glaze and starch in selected parts by weight, disperse them in a solvent, and mix them uniformly to obtain sintering aid slurry; wherein, the solvent is Dehydrated alcohol; The consumption of described dehydrated alcohol is 90 parts;

[0053] (2) Dispersion of fibers: get quartz glass fiber and quartz fiber ...

Embodiment 3

[0058] The high-temperature-resistant wave-transmitting thermal insulation tile of this embodiment includes the following components in parts by weight: 70 parts of quartz glass fiber; 20 parts of quartz fiber cotton; 10 parts of sintering aid; 10 parts of starch.

[0059] Wherein, the sintering aid is formed by mixing boron nitride and glass glaze in a weight ratio of 1:4. The diameter of the quartz glass fiber is 1-10um, the length is 2-5mm, SiO 2 Weight content ≥ 99%; the diameter of the quartz fiber cotton is 1-5um, SiO 2 Weight content ≥ 99%.

[0060] Its preparation method is as follows:

[0061] (1) Preparation of sintering aid slurry: take boron nitride, glass glaze and starch in selected parts by weight, disperse them in a solvent, and mix them uniformly to obtain sintering aid slurry; wherein, the solvent is Dehydrated alcohol; The consumption of described dehydrated alcohol is 90 parts;

[0062] (2) Dispersion of fibers: get quartz glass fiber and quartz fiber c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com