Organic fertilizer special for Chinese flowering cabbage and preparation method thereof

A technology of organic fertilizer and Chinese cabbage, applied in the direction of organic fertilizer, application, phosphate fertilizer, etc., can solve the problems of low yield of Chinese cabbage, long growth cycle, etc., and achieve the effect of increasing survival rate, high nutrient content, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

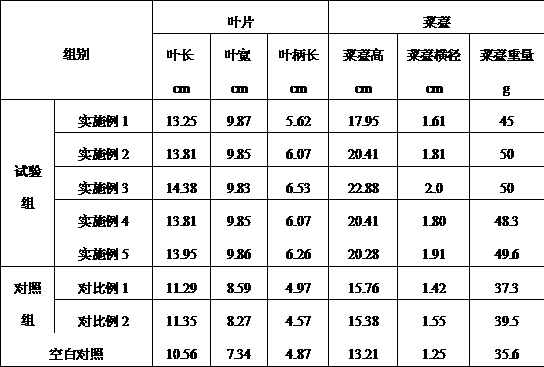

Examples

Embodiment 1

[0022] A special organic fertilizer for cabbage, comprising the following raw materials in parts by weight: 50-90 parts of fungus residue, 50-90 parts of peanut bran, 50-90 parts of chicken manure, 50-90 parts of soybean meal, straw, dihydrogen phosphate 15-30 parts of sodium, 3-5 parts of borax, 3-5 parts of sodium selenate, 3-5 parts of EDTA chelated iron.

[0023] In parts by weight, the following raw materials are included: 60-80 parts of fungus residue, 60-80 parts of peanut bran, 60-80 parts of chicken manure, 60-80 parts of soybean meal, 20-25 parts of sodium dihydrogen phosphate, 3.5-4.5 parts of borax 3.5-4.5 parts of sodium selenate, 3.5-4.5 parts of EDTA chelated iron.

[0024] The following raw materials are included in parts by weight: 70 parts of fungus residue, 70 parts of peanut bran, 70 parts of chicken manure, 70 parts of soybean meal, 22 parts of sodium dihydrogen phosphate, 4 parts of borax, 4 parts of sodium selenate, EDTA chelated iron 4 parts.

[0025]...

Embodiment 2

[0030] A special organic fertilizer for cabbage, comprising the following raw materials in parts by weight: 50-90 parts of fungus residue, 50-90 parts of peanut bran, 50-90 parts of chicken manure, 50-90 parts of soybean meal, straw, dihydrogen phosphate 15-30 parts of sodium, 3-5 parts of borax, 3-5 parts of sodium selenate, 3-5 parts of EDTA chelated iron.

[0031] In parts by weight, the following raw materials are included: 60-80 parts of fungus residue, 60-80 parts of peanut bran, 60-80 parts of chicken manure, 60-80 parts of soybean meal, 20-25 parts of sodium dihydrogen phosphate, 3.5-4.5 parts of borax 3.5-4.5 parts of sodium selenate, 3.5-4.5 parts of EDTA chelated iron.

[0032] The following raw materials are included in parts by weight: 70 parts of fungus residue, 70 parts of peanut bran, 70 parts of chicken manure, 70 parts of soybean meal, 22 parts of sodium dihydrogen phosphate, 4 parts of borax, 4 parts of sodium selenate, EDTA chelated iron 4 parts.

[0033]...

Embodiment 3

[0038] A special organic fertilizer for cabbage, comprising the following raw materials in parts by weight: 50-90 parts of fungus residue, 50-90 parts of peanut bran, 50-90 parts of chicken manure, 50-90 parts of soybean meal, straw, dihydrogen phosphate 15-30 parts of sodium, 3-5 parts of borax, 3-5 parts of sodium selenate, 3-5 parts of EDTA chelated iron.

[0039] In parts by weight, the following raw materials are included: 60-80 parts of fungus residue, 60-80 parts of peanut bran, 60-80 parts of chicken manure, 60-80 parts of soybean meal, 20-25 parts of sodium dihydrogen phosphate, 3.5-4.5 parts of borax 3.5-4.5 parts of sodium selenate, 3.5-4.5 parts of EDTA chelated iron.

[0040] The following raw materials are included in parts by weight: 70 parts of fungus residue, 70 parts of peanut bran, 70 parts of chicken manure, 70 parts of soybean meal, 22 parts of sodium dihydrogen phosphate, 4 parts of borax, 4 parts of sodium selenate, EDTA chelated iron 4 parts.

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com