Electroluminescent compound, OLED display panel and electronic equipment

A display panel and luminescence technology, which is applied to compounds of elements of group 5/15 of the periodic table, compounds containing elements of group 3/13 of the periodic table, luminescent materials, etc., can solve problems such as performance needs to be improved, and achieve improved The effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the compound provided by the present invention is prior art, and the synthetic method of following compound is provided exemplarily below:

[0067] (1)A 1 and A 2 When each is independently selected from a group containing a carbonyl group, the synthesis method is as follows (taking M3 as an example):

[0068]

[0069] Weigh S1(30mmol), S2(65mmol), Pd(OAc) 2 (1.5mmol), P(t-Bu) 3 (3mmol) and K 2 CO 3 (120mmol), add 120mL toluene to dissolve. Under nitrogen atmosphere, it was heated to 120° C. for 48 h. The reaction mixture was cooled to room temperature. The reaction mixture was poured into 600 mL of cold water and stirred for 6 h. Extract with dichloromethane (3 x 60 mL) and collect the organic phase. with anhydrous Na 2 SO 4 The organic phase is dried. The solvent was distilled off under reduced pressure to obtain a crude product. Finally, the sample was purified by column chromatography to obtain the target product M3 (23.4 mm...

Embodiment 1

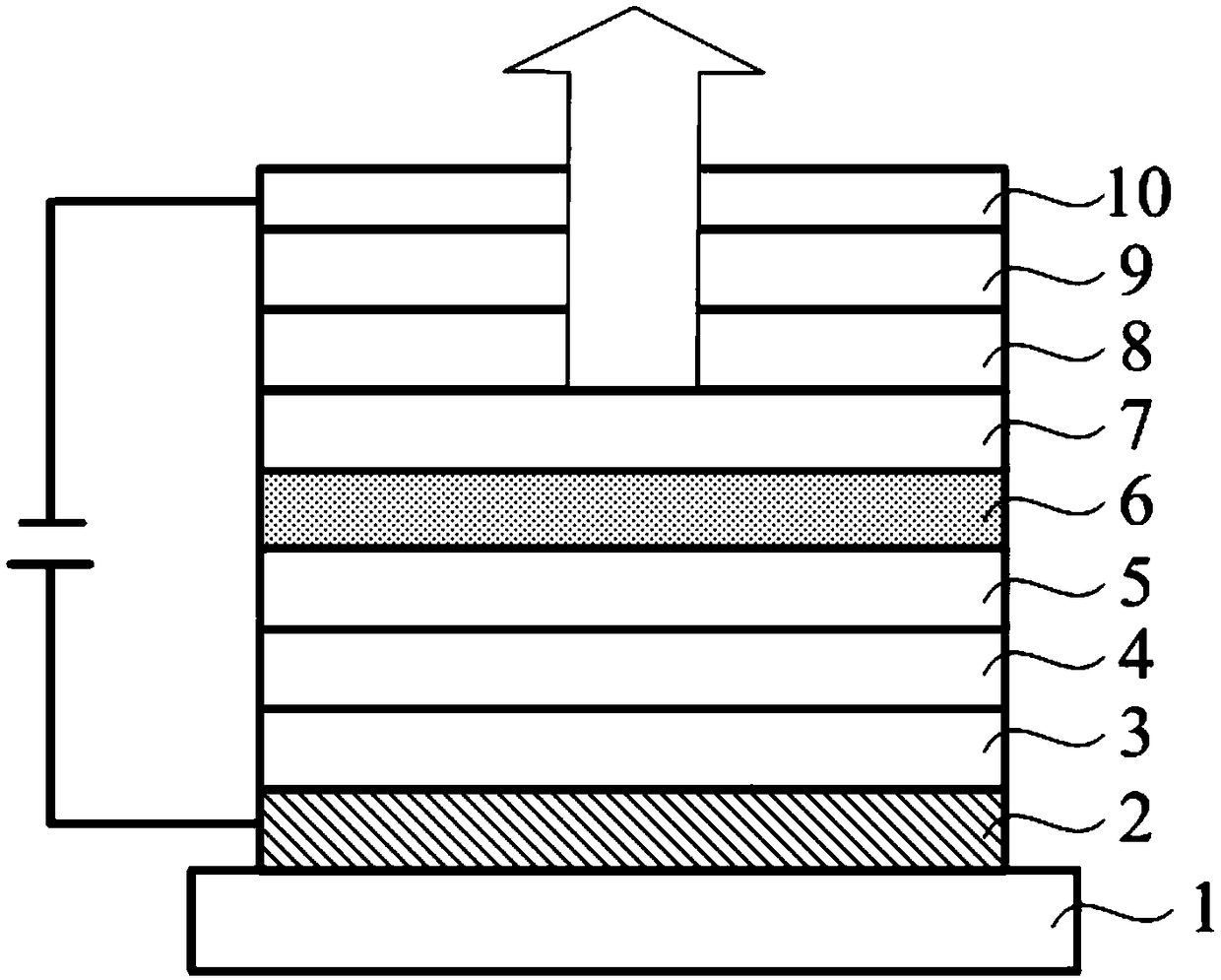

[0081] This embodiment provides an OLED display panel N1, such as figure 2 As shown, the display panel includes: a substrate 1, an ITO anode 2, a hole injection layer 3, a first hole transport layer 4, a second hole transport layer 5, a light emitting layer 6, a first electron transport layer 7, a second electron transport layer Transport layer 8, electron injection layer 9 and cathode 10 (aluminum electrode), wherein the thickness of ITO anode 2 is 10nm, the thickness of hole injection layer 3 is 5nm, the thickness of the first hole transport layer 4 is 50nm, the second hole The thickness of the hole transport layer 5 is 10nm, the thickness of the light emitting layer 6 is 20nm, the thickness of the first electron transport layer 7 is 5nm, the thickness of the second electron transport layer 8 is 20nm, the thickness of the electron injection layer 9 is 1nm, the aluminum electrode The thickness of 10 is 15 nm.

[0082] The preparation steps of the OLED display panel N1 are a...

Embodiment 2

[0095] The difference from Example 1 is that an OLED display panel N2 is provided, and compound M1 is replaced by compound M2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com