A kind of preparation method of hydrophobically modified cellulose polymer micelles

A technology of cellulose polymer and hydrophobic modification, which is applied in the field of preparation of hydrophobically modified cellulose polymer micelles, can solve the problems of limited method of amphiphilic polymer, complicated reaction, difficult product handling, etc., and achieves good storage. Effects of Stability and Dilution Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing hydrophobically modified cellulose polymer micelles, a method for preparing hydrophobically modified cellulose polymer micelles, comprising the following specific steps:

[0036] Step 1, weighing raw materials:

[0037] Step 2, prepare cellulose solution:

[0038] Adding the weighed sodium hydroxide and urea into water in sequence to obtain a mixed solution of sodium hydroxide and urea, precooling; then throwing in cellulose, and stirring the obtained cellulose solution;

[0039] Step 3, preparation of cellulose gelatin polymer:

[0040] Add gelatin aqueous solution dropwise to the cellulose solution, stir at room temperature for 1 hour, add epichlorohydrin while stirring, react for 3 to 5 hours, undergo dialysis, dispersion, standing, and separation to obtain a water-soluble cellulose gelatin polymer;

[0041] Step 4, preparation of hydrophobically modified cellulose polymer:

[0042] Add brominated long-chain alkyl grou...

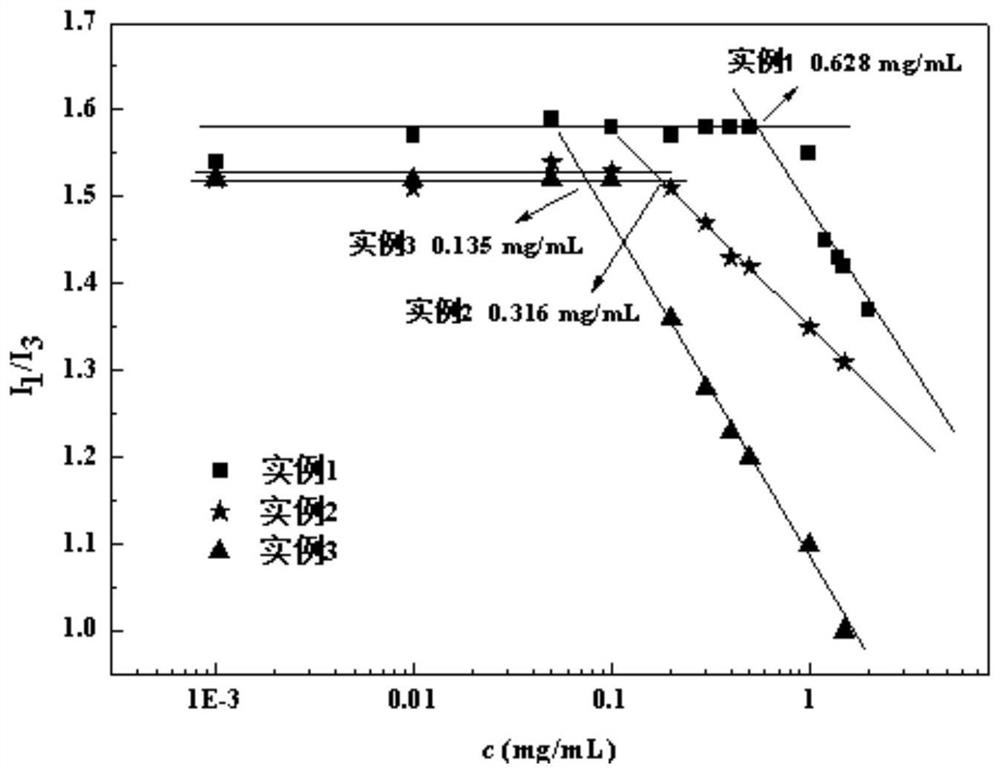

Embodiment 1

[0060]Dissolve 2 g of cellulose in 98 g of sodium hydroxide and urea mixed solution precooled to -12°C to obtain a cellulose solution; add 2.78 g of an 8% gelatin aqueous solution dropwise to the cellulose solution, and stir at room temperature for 1 h. Subsequently, 6 g of epichlorohydrin was added dropwise, the reaction was continued for 3 h, and then the water-soluble cellulose gelatin polymer was obtained through dialysis, dispersion, standing, and separation;

[0061] Weigh 20g of cellulose gelatin polymer aqueous solution in a 100mL three-necked flask, adjust the pH of the system to 11, add n-octane bromide dropwise, wherein the molar ratio of n-octane bromide to cellulose glucose unit is 6:1, and control the reaction The temperature is 40°C, stirred for 8 hours, stopped the reaction, neutralized with hydrochloric acid, and after the system temperature dropped to room temperature, the reaction product was precipitated with absolute ethanol and washed 3 times, and vacuum-d...

Embodiment 2

[0067] Dissolve 3 g of cellulose in 97 g of sodium hydroxide and urea mixed solution precooled to -11°C to obtain a cellulose solution; add 8.82 g of an aqueous gelatin solution with a mass fraction of 8.5% to the cellulose solution dropwise, and stir at room temperature for 1 h. Subsequently, 7.5 g of epichlorohydrin was added dropwise, and the reaction was continued for 3.5 h, followed by dialysis, dispersion, standing, and separation to obtain a water-soluble cellulose gelatin polymer;

[0068] Weigh 20g of cellulose gelatin polymer aqueous solution in a 100mL three-neck flask, adjust the pH of the system to 12, add bromododecane dropwise, wherein the molar ratio of bromododecane to cellulose glucose unit is 8:1, and control the reaction The temperature is 50°C, stirred for 7 hours, stopped the reaction, neutralized with hydrochloric acid, and after the system temperature dropped to room temperature, the reaction product was precipitated with absolute ethanol and washed 4 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com