Aliphatic polythioester preparation method

A polythioester and aliphatic technology is applied in the field of preparation of aliphatic polythioesters, which can solve problems such as being unsuitable for large-scale production of polythioesters, and achieve precise regulation of polymer structure and simple and easy polymerization method. The effect of various operations and product types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

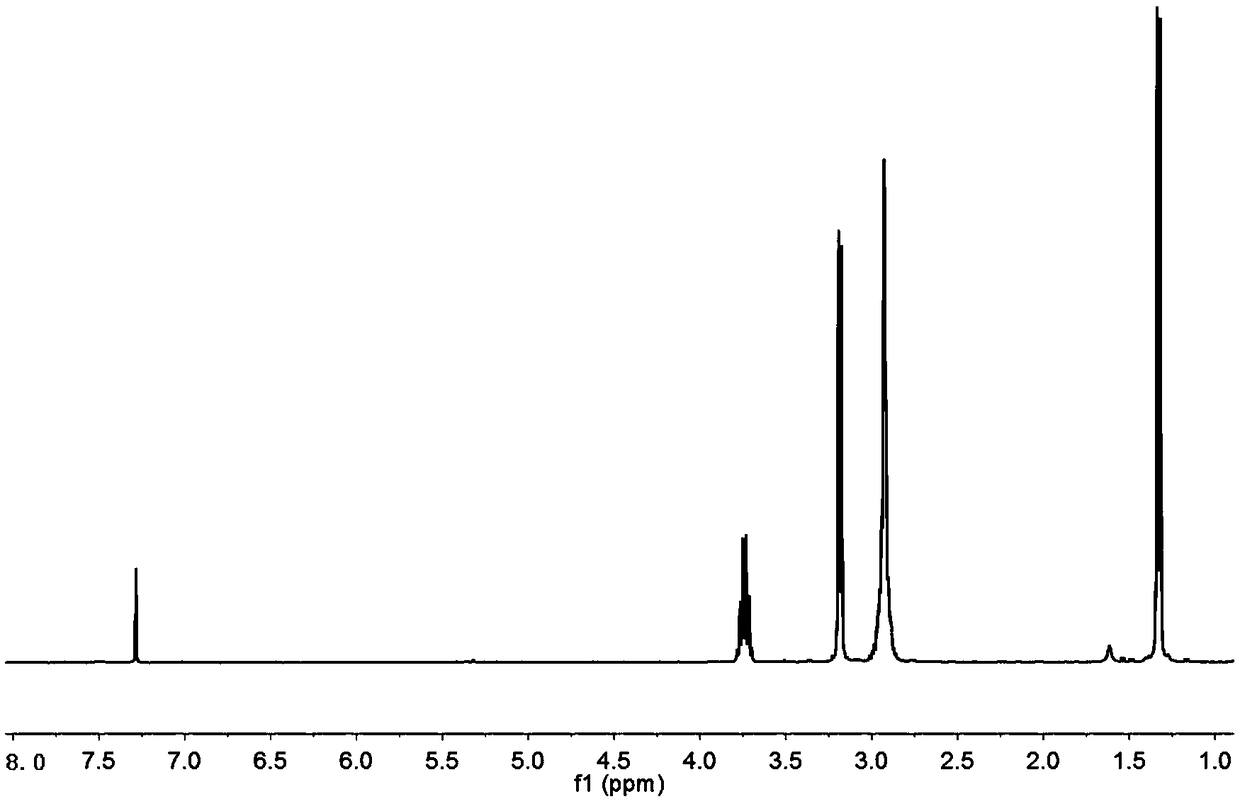

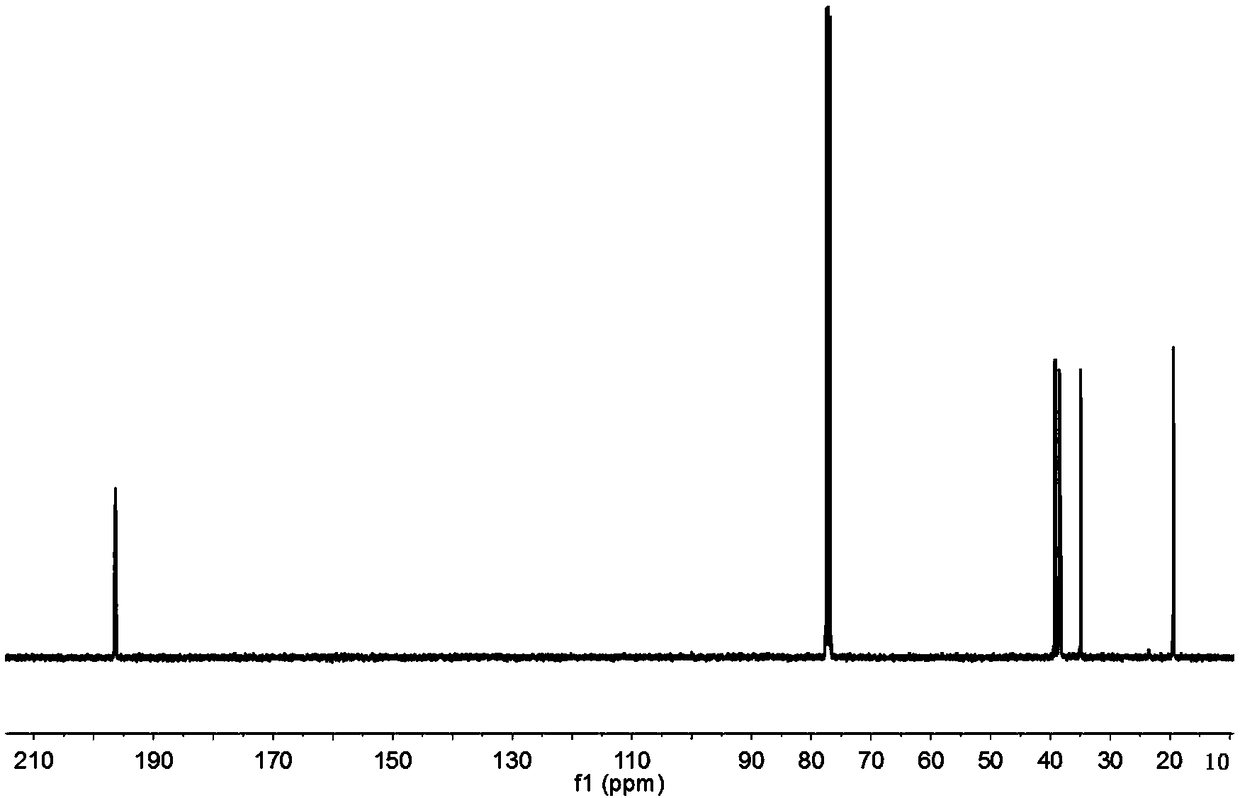

Embodiment 1

[0033] Dry the 100mL pressure-resistant glass bottle equipped with a magnet at 130°C for more than 12 hours, vacuumize it until it cools down to room temperature, and flush it with nitrogen to prepare for use. Under the protection of nitrogen, weigh a certain amount of initiator bis(triphenylphosphoryl) ammonium chloride, cyclothioalkane 1a and aliphatic thioanhydride 2a at room temperature, cyclothioalkane, aliphatic thioanhydride and initiator The molar ratio is 2000:1000:1. It was then placed in an oil bath at 25°C and magnetic stirring was started. Reaction 4h, stop stirring. A very small amount of the reaction mixture was removed for the 1 H NMR and GPC tests. 1 H NMR test showed that the conversion rate of aliphatic thioanhydride was >99%, and GPC test showed that the polymer molecular weight was 23400 g / mol. Purify the remaining reaction polymer. Purification of the polymer: first dissolve the crude product in a small amount of dichloromethane, then add a large amou...

Embodiment 2

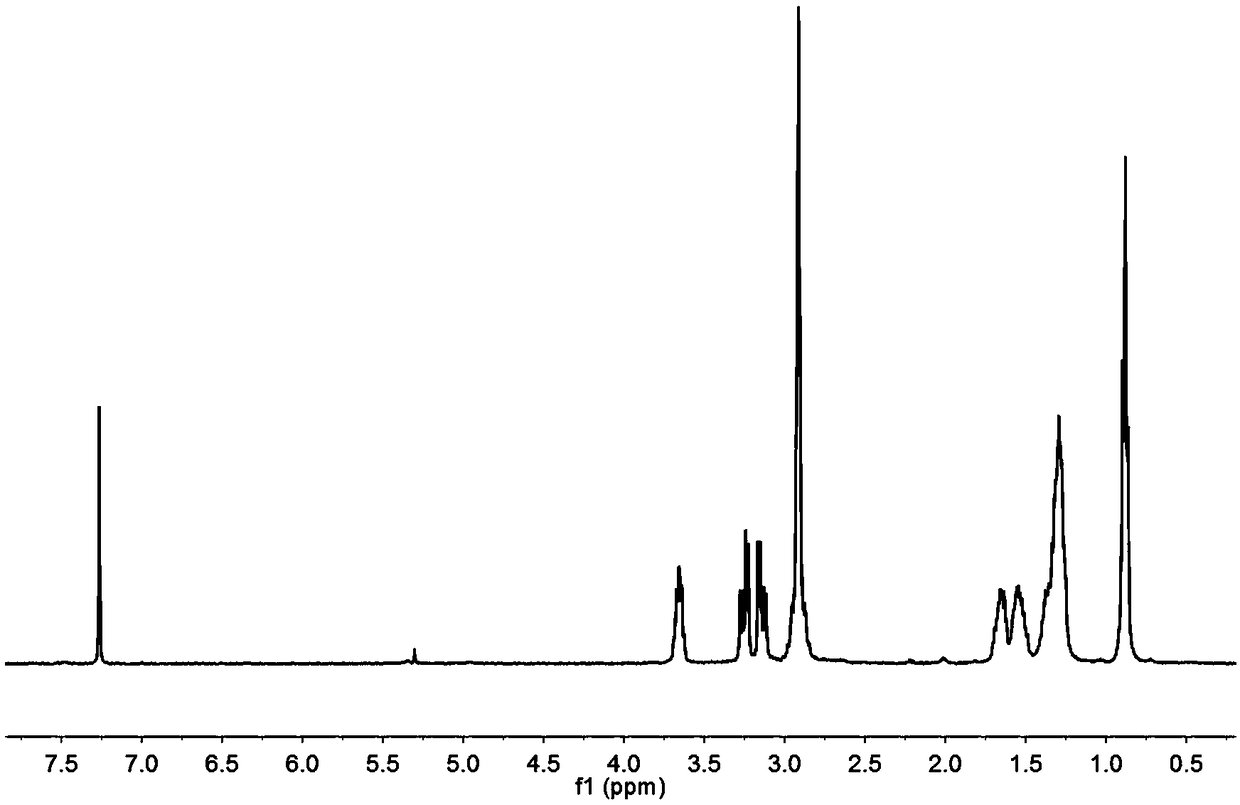

[0035] Dry the 100mL pressure-resistant glass bottle equipped with a magnet at 130°C for more than 12 hours, vacuumize it until it cools down to room temperature, and flush it with nitrogen to prepare for use. Under nitrogen protection, take by weighing a certain amount of initiator bis(triphenylphosphoryl) ammonium acetate, epithioalkane 1a and aliphatic thioanhydride 2c at room temperature, the mixture of epithioalkane, aliphatic thioanhydride and initiator The molar ratio is 2000:1000:1. It was then placed in an oil bath at 25°C and magnetic stirring was started. Reaction 4h, stop stirring. A very small amount of the reaction mixture was removed for the 1 H NMR and GPC tests. 1 H NMR test showed that the conversion rate of aliphatic thioanhydride was >99%, and GPC test showed that the polymer molecular weight was 31200 g / mol. Purify the remaining reaction polymer. Purification of the polymer: first dissolve the crude product in a small amount of dichloromethane, then ad...

Embodiment 3

[0037] Dry the 100mL pressure-resistant glass bottle equipped with a magnet at 130°C for more than 12 hours, vacuumize it until it cools down to room temperature, and flush it with nitrogen to prepare for use. Under nitrogen protection, room temperature takes by weighing a certain amount of initiator bis(triphenylphosphoryl) ammonium nitrate, epithioalkane 1b and aliphatic thioanhydride 2a, the mixture of epithioalkane, aliphatic thioanhydride and initiator The molar ratio is 2000:1000:1. Then put it into an oil bath at 40°C and start magnetic stirring. Reaction 2h, stop stirring. A very small amount of the reaction mixture was removed for the 1 H NMR and GPC tests. 1 H NMR test showed that the conversion rate of aliphatic thioanhydride was >99%, and GPC test showed that the polymer molecular weight was 40800 g / mol. Purify the remaining reaction polymer. Purification of the polymer: first dissolve the crude product in a small amount of dichloromethane, then add a large amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com